Wine Pumps: Precision Pumping for the Winemaking Industry 2025

In the world of winemaking, precision, hygiene, and gentle handling are non-negotiable. Whether you’re transferring must during fermentation or racking delicate vintages into barrels, a wine pump is an essential part of maintaining quality and preserving the character of your wine.

At MultiTorque, we supply and service high-quality pumps for a wide range of food and beverage applications—including wine production. From boutique vineyards to commercial wineries across Australia, we deliver pumps that are engineered for performance, durability, and most importantly, the gentle transfer that wine demands.

🔗 Visit MultiTorque

🔗 Follow us on LinkedIn

What is a Wine Pump?

A wine pump is a sanitary pump used in the winemaking process to transfer wine or grape must from one container to another. It is specially designed to handle liquid with a high risk of oxidation or contamination, and to move wine without damaging its taste, aroma, or structure.

Unlike general-purpose industrial pumps, wine pumps are made from food-grade materials, often with gentle pumping action to avoid disturbing delicate compounds or tannins in the wine.

Common Applications for Wine Pumps

Wine pumps are used at multiple stages of the winemaking process:

| Stage | Use of Wine Pump |

|---|---|

| Crush & Fermentation | Transferring grape must to fermentation tanks |

| Pump Over (Remontage) | Circulating wine over grape skins for extraction |

| Racking | Moving wine off lees into clean containers |

| Filtration & Bottling | Transferring clarified wine to filtration systems or bottling lines |

| Barrel Transfers | Gently moving wine in and out of oak barrels |

Types of Wine Pumps

Different phases of winemaking require different pump types, and selecting the right one can make a big difference in wine quality.

🍷 1. Flexible Impeller Pumps

- Ideal for low to medium-viscosity liquids

- Gentle on product, self-priming

- Often reversible for easy racking and cleaning

- Commonly used in small wineries or for barrel work

🍇 2. Peristaltic Pumps

- Best for delicate must or wines with solids

- Fluid never contacts moving parts (high hygiene)

- Extremely gentle with zero shear

- Common in premium winemaking environments

💧 3. Diaphragm Pumps (AODD)

- Air-operated, ideal for portable wine pumps

- Can handle solids and foamy liquids

- Food-grade construction with minimal oxidation

🔄 4. Centrifugal Pumps (Sanitary)

- High-volume applications

- Used in bottling and filtration

- Not as gentle—best suited for later stages

What Makes a Good Wine Pump?

When sourcing a wine pump, look for the following:

✅ Food-Grade Materials

Stainless steel 316, EPDM seals, or other sanitary materials ensure no contamination of the wine.

✅ Gentle Handling

Low-shear or non-contact pumping prevents oxidation and protects wine integrity.

✅ Easy to Clean (CIP)

Winery equipment needs frequent cleaning. A wine pump should support Clean-in-Place (CIP) or be easy to disassemble.

✅ Reversible Flow

Great for filling and draining barrels or tanks, and gives greater flexibility in layout.

✅ Mobility

Portable trolley-mounted pumps are ideal for wineries that need to move equipment between tanks, crush pads, and barrels.

Industries We Serve

At MultiTorque, we work with a wide range of businesses in the food and beverage sector, including:

- Boutique vineyards & cellar doors

- Large commercial wineries

- Contract winemakers

- Breweries and cider houses

- Juice and beverage manufacturers

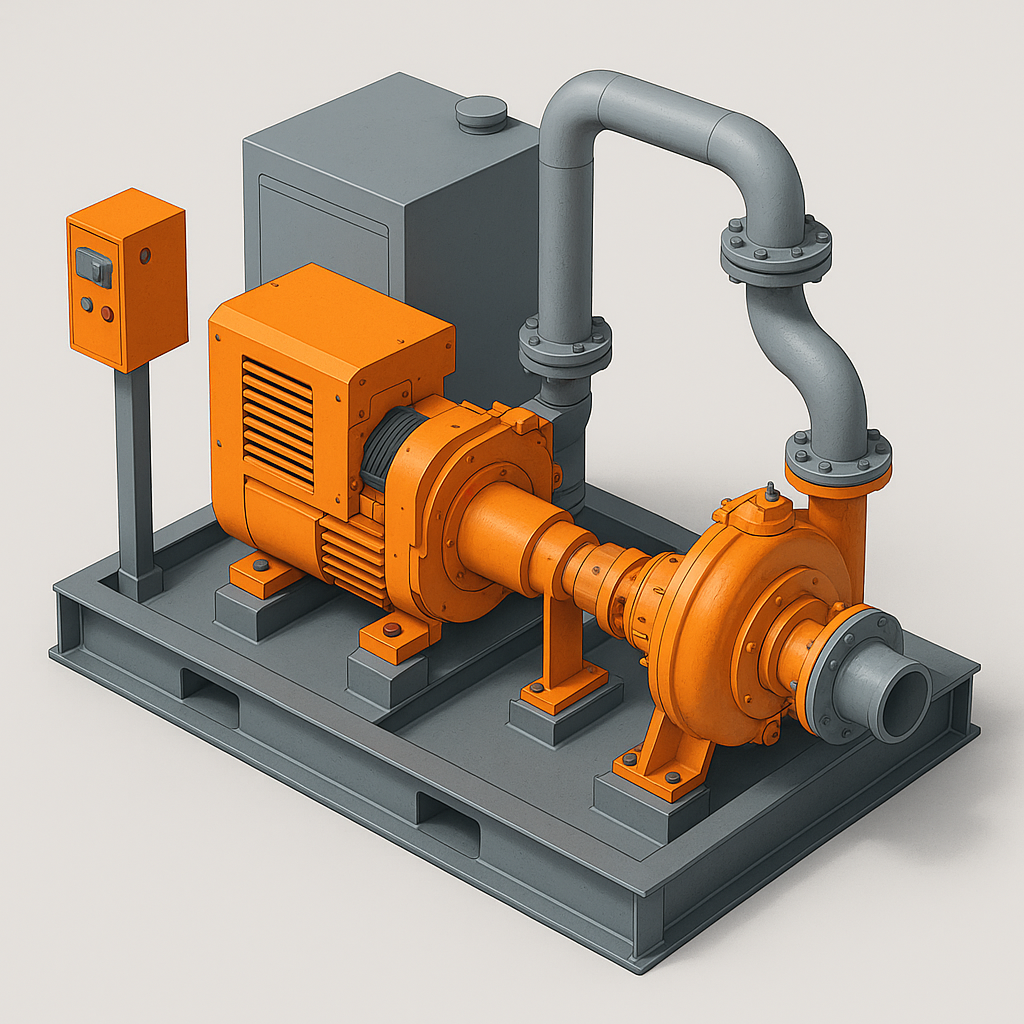

Custom Pumping Solutions for Wineries

No two wineries are the same. That’s why we offer custom wine pump packages including:

- Portable pump skids on stainless trolleys

- Barrel transfer setups with hoses and fittings

- Integrated control panels for speed and flow control

- Food-grade hose and clamp kits

- Air compressors for AODD systems

- Replacement seals, impellers, and spares

Whether you’re scaling up production or upgrading ageing infrastructure, we’ll help you choose the right wine pump for your needs—and support it long after install.

Servicing & Repairs

Wine pumps operate during peak harvest times—so downtime is not an option. That’s why MultiTorque offers:

- Scheduled servicing during off-season

- Emergency pump rebuilds in our Perth & Brisbane workshops

- Seal and impeller replacements

- Hygienic cleaning, testing, and reassembly

We also carry spare parts for major pump brands, and offer fast turnaround for urgent winery repairs.

Why Choose MultiTorque?

With over 15 years of experience supplying pumps to Australian industries, we’ve become a trusted partner for reliable pumping systems—whether you’re bottling wine or dewatering a mine.

🛠️ Expert Support

We’re not just salespeople—we’re pump technicians. We help you spec, size, and maintain your equipment.

🍷 Wine Industry Knowledge

We understand the unique pressures and seasonality of winemaking, and offer equipment tailored for vintage time.

🇦🇺 National Support

From Margaret River to the Hunter Valley, we supply and support winemakers across Australia.

Ready to Upgrade Your Winery’s Pumping System?

If you need a pump that’s gentle on your wine but tough on performance, talk to MultiTorque today. We’ll match you with a solution built to last—and built for flavour.

📞 Call us at 1300 726 525

📧 Email: sales@multitorque.com

🌐 www.multitorque.com.au

🔗 Follow us on LinkedIn