Vane Pump Systems: Smooth, Reliable Fluid Transfer for Industrial Use 2025

When you need precise, pulse-free flow and dependable performance, a vane pump is one of the best choices available. Commonly used in fuel systems, hydraulic applications, and chemical transfer, vane pumps deliver consistent pressure, excellent suction capabilities, and long-term durability—even in demanding industrial settings.

At MultiTorque, we supply and service high-quality vane pumps across Australia, including custom systems tailored to mining, manufacturing, transport, and more. With 15+ years of pump expertise, we make sure your equipment runs at full torque, all day, every day.

What Is a Vane Pump?

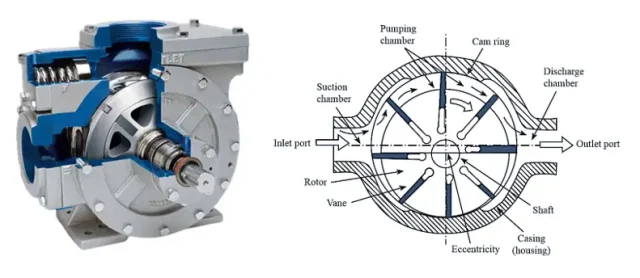

A vane pump is a type of positive displacement pump that uses vanes mounted to a rotor. As the rotor turns inside a cavity, the vanes slide in and out to trap and move fluid from the inlet to the outlet.

Vane pumps are known for:

-

Smooth and quiet operation

-

Self-priming capabilities

-

Steady, low-pulsation flow

-

Excellent suction performance

They can handle a wide variety of fluids, from light oils and fuels to viscous chemicals and refrigerants.

How Vane Pumps Work

The rotor spins inside an offset cam ring, creating chambers that expand and contract as the vanes rotate. This action:

-

Draws fluid in through the inlet

-

Traps the fluid between vanes

-

Forces it out through the outlet under pressure

The vanes maintain contact with the cam ring through centrifugal force, springs, or hydraulic pressure, depending on the model.

Applications of Vane Pumps

Vane pumps are widely used across multiple industries due to their reliability and ability to handle both thin and thick fluids.

🔧 Common applications include:

-

Fuel transfer systems (diesel, petrol, aviation fuel)

-

Hydraulic power units

-

Chemical dosing and transfer

-

Lubrication systems

-

Refrigeration and HVAC systems

-

Automated spray and wash systems

-

Mobile machinery like road sweepers and mining trucks

Whether you’re running a fixed plant or a mobile setup, a vane pump provides the consistency your system needs.

Key Benefits of Vane Pumps

-

✅ Pulse-Free Output – Ideal for applications needing steady flow without fluctuations

-

✅ Self-Priming – Excellent suction for dry-start and intermittent flow conditions

-

✅ Compact Design – Space-saving in mobile or confined installations

-

✅ Wear-Resistant Options – Available in materials that handle corrosive or abrasive media

-

✅ Quiet Operation – Lower noise levels than many other pump types

-

✅ Easy Maintenance – Simple internal design for fast servicing

Vane Pump vs Gear Pump: Which to Choose?

While gear pumps are also popular for transferring oil, fuel, and chemicals, vane pumps offer several unique advantages:

-

Better suction and priming capabilities

-

Smoother, quieter operation

-

Lower internal wear under low-viscosity conditions

If you’re working with light fuels or want lower noise and vibration, a vane pump is often the superior option.

Custom Pump Solutions at MultiTorque

At MultiTorque, we don’t just sell pumps—we build complete systems. Whether you need a standalone pump or a fully integrated setup, we can design and deliver:

-

Vane pump skids

-

Hose and nozzle kits

-

Electrical or diesel-powered configurations

-

Mobile trailers and pump carts

-

Control panels and automation options

All backed by our in-house team and expert after-sales support across Australia.

Get a Pump That Performs

If you’re looking for a vane pump that delivers quiet, consistent performance under pressure, MultiTorque has your back. Our pump experts will help you choose the right model, install it correctly, and keep it running like new.

📞 Call 1300 726 525

🌐 Visit www.multitorque.com.au

🔗 Follow us on LinkedIn

📧 Email: sales@multitorque.com