Starter Pneumatic: Reliable Engine Starting Solutions for Heavy-Duty Applications 2025

In industries where reliability and safety are critical, pneumatic starters (often called starter pneumatic systems) play a vital role in ensuring diesel and gas engines start smoothly and efficiently. At MultiTorque, we specialize in supplying, servicing, and repairing starter pneumatic systems for a wide range of industrial applications across Australia.

What Is a Starter Pneumatic?

A starter pneumatic is an air-powered device designed to initiate engine rotation in diesel or gas engines. Unlike traditional electric starters, pneumatic starters utilize compressed air to drive a motor that engages with the engine’s flywheel, cranking the engine until it starts.

This technology is especially valued in environments where electrical sparks pose safety risks or where electrical power availability is limited or unreliable.

How Does a Starter Pneumatic Work?

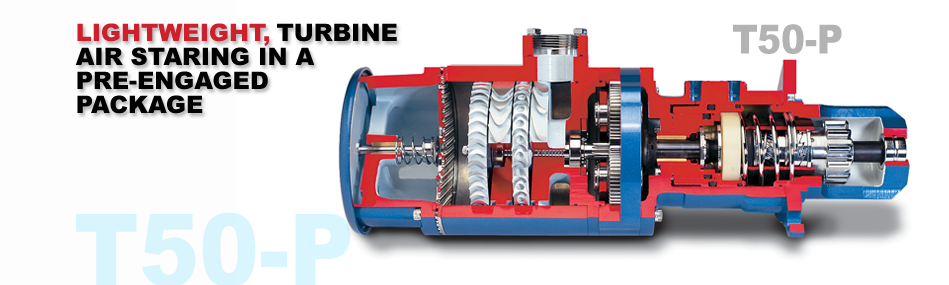

The pneumatic starter system operates by directing compressed air into a motor that converts air pressure into rotational mechanical force. The motor spins a pinion gear which meshes with the engine’s flywheel ring gear, turning the engine over to start combustion.

Key components include:

- Compressed air source (tank or compressor)

- Starter motor powered by compressed air

- Control valves to regulate air flow

- Pinion gear that engages the engine flywheel

- Air filtration and lubrication systems

Advantages of Pneumatic Starters

1. Safe in Hazardous Environments

Pneumatic starters generate no sparks, making them ideal for explosive atmospheres like oil refineries, gas plants, and mining sites.

2. High Reliability

They perform well in extreme temperatures and dusty or wet conditions where electric starters may fail.

3. Low Maintenance

Fewer electrical components mean less maintenance and downtime.

4. Multiple Start Attempts

Compressed air can power multiple start attempts without recharging, vital in remote or off-grid operations.

Common Applications of Starter Pneumatic Systems

- Mining equipment such as excavators and pumps

- Oil and gas rigs and offshore platforms

- Marine diesel engines

- Construction machinery

- Backup generators and power plants

Why Choose MultiTorque for Your Starter Pneumatic Needs?

- Over 15 years of experience in pneumatic starter supply and service

- Expertise with top brands and custom solutions

- Nationwide support including repairs, parts, and system design

- Commitment to safety, reliability, and customer satisfaction

Maintenance and Troubleshooting Tips

To keep your starter pneumatic system in top shape:

- Regularly inspect air filters and replace as needed

- Ensure air supply is dry and clean to prevent internal damage

- Lubricate moving parts per manufacturer guidelines

- Check control valves and hoses for leaks

- Monitor pinion gear engagement and wear

MultiTorque offers comprehensive service plans to help you avoid costly downtime.

Contact MultiTorque Today

Need a robust starter pneumatic system or expert servicing? MultiTorque is your trusted partner.

📞 Call us at 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit www.multitorque.com.au

🔗 Connect on LinkedIn: MultiTorque Industries