Optimising Slurry Pump Systems for Industrial and Mining Operations 2025

When you need to move abrasive, solid-laden materials reliably—whether in mining, dredging, or wastewater treatment—a slurry pump system is essential. At MultiTorque, we specialise in delivering rugged, custom-designed slurry pump systems built for Australia’s most demanding environments.

🔧 What Is a Slurry Pump System?

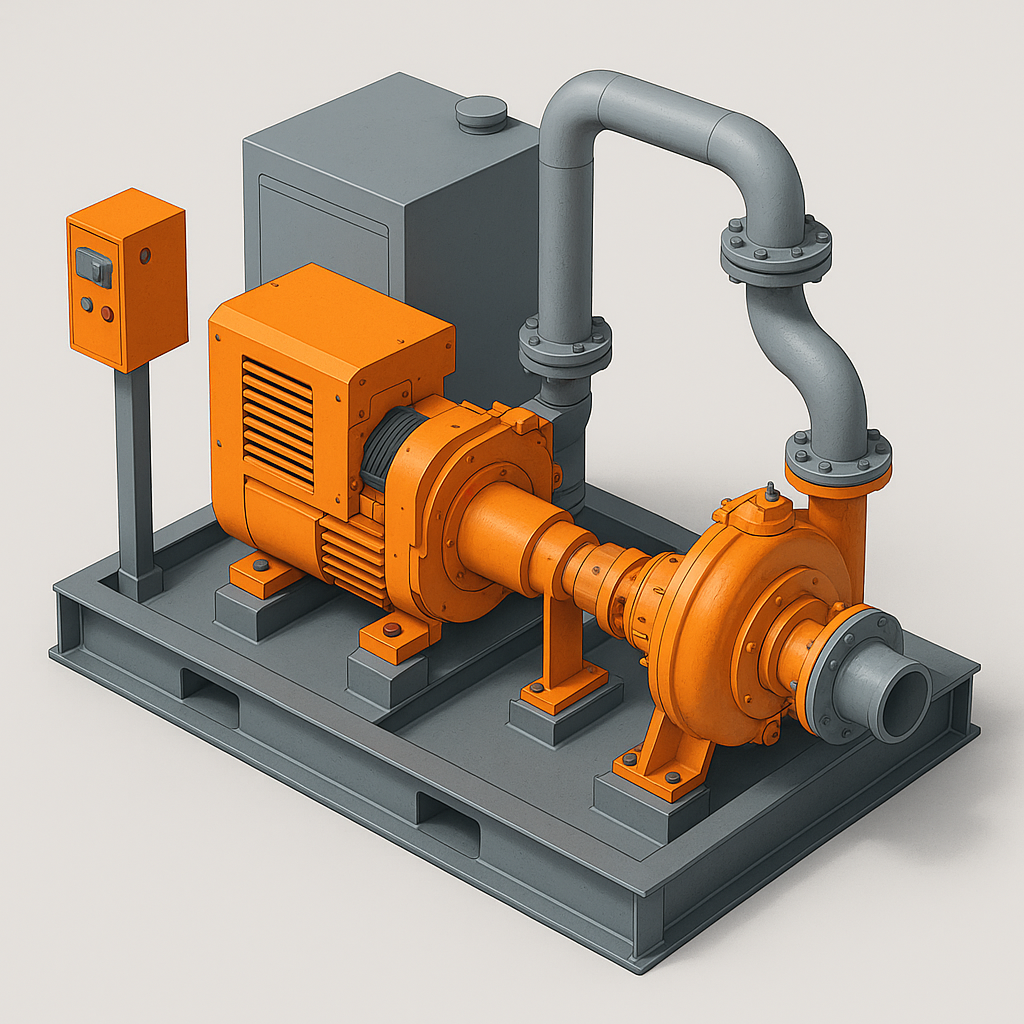

A slurry pump system typically includes a heavy-duty centrifugal or positive-displacement pump, skid-mounted or trailer-mounted, equipped with wear-resistant impellers, liners, controls, and piping. These systems are designed to handle high-solids content with minimal downtime—unlike standard pumps, slurry pumps are forged for durability under extreme conditions

⛏️ Why Correctly Specifying Matters

A poorly specified system leads to high energy use, frequent wear, and costly breakdowns. Australian mines commonly use slurry pumps around the clock, demanding precision in pump selection to match best efficiency point (BEP) performance miningmagazine.com.au. Ensuring optimal BEP lowers long-term costs and extends component life.

🛠️ System Configurations: What to Choose

1. Centrifugal Slurry Pumps

Optimal for high-flow operations, these are available in horizontal, vertical, and submersible designs. Submersible types offer cleaner installations and quiet operation

2. Positive-Displacement and Progressive-Cavity Pumps

Better suited for high-viscosity or precision dosing jobs, these are ideal for chemical or oil-laden slurries—they’re dependable and accurate

3. Chopper & Rotary-Lobe Pumps

When solids cause clogs, chopper pumps macerate the slurry to prevent blockages, while rotary-lobe pumps offer low-shear handling in food or wastewater applications

🌍 Applications We Serve

Mining & Quarrying – For tailings, mill discharge, and heavy grit, slurry pump systems are indispensable. High chrome impellers and chromium steel liners resist abrasive damage .

Dredging & Water Management – Slurry pumps help dredge ponds and remove sediments, efficiently managing water-based mining and industrial cleaning .

Wastewater & Agriculture – Sludge, manure, or biosolids? With chopper or submersible designs, these systems reduce downtime and improve operational consistency .

🏆 Real‑World Success Stories

- Mining Magazine Australia reported that optimally specified slurry pumps can vastly cut operating costs while boosting reliability—achieved by aligning pump performance with site conditions esitechgroup.com+12miningmagazine.com.au+12metso.com+12.

- Weir Minerals/Warman MCR 250 saw a 130% increase in wear life and annual savings of US $70,000 at a gold mine, thanks to proper pump selection and pump box level control global.weir.

- ESI Technologies replaced a failing centrifugal slurry pump with a Goulds XHD unit, extending wear part life from 8–10 weeks to over 35 weeks—a 5× improvement esitechgroup.com.

- Sulzer SNS pump proved more efficient in mine dewatering compared to standard slurry pumps, saving EUR 24,000 per year in energy per unit sulzer.com.

🧩 MultiTorque’s Approach to Slurry Pump Systems

At MultiTorque, we don’t just install pumps—we provide fully engineered slurry pump solutions:

✔️ Custom Engineering & Fabrication

Whether you need horizontal, vertical, submersible, or skid-mounted systems, we tailor each solution. We integrate control panels, telemetry, variable-frequency drives, and chemical-resistant materials for rugged performance.

✔️ Proper Specification

We examine slurry composition, flow needs, head pressure, and solids content to specify the ideal pump type, material, and power source—optimised around BEP.

✔️ Service & Ongoing Support

We offer regular maintenance, wear-part swapping, rebuilds, and diagnostics. From our Brisbane and Perth branches, we support clients nationwide.

✔️ Trial, Test, Iterate

Using intelligence from customers and local conditions, we support ongoing optimisation—like pump box level control and predictive wear analysis.

⚙️ Maintenance Best Practices

Regular inspection and performance checks are vital:

- Replacing liners and impellers before performance drops

- Monitoring vibration, flow, pressure anomalies

- Keeping spares on-site for rapid swaps

- Scheduling rebuilds to prevent unexpected outages vogelsang.info+15razor-labs.com+15multitorque.com.au+15multitorque.com.auglobal.weircedronmagazine.com+2esitechgroup.com+2multitorque.com.au+2

🌟 Benefits of Partnering with MultiTorque

- Lower operational costs through energy-efficient, well-specified systems

- Reduced maintenance downtime with wear-resistant pump components

- Higher uptime via custom systems built for reliability

- Australia-wide support plus local technical expertise

📞 Get Your Slurry Pump System Right

If you’re ready to upgrade or install a slurry pump system, MultiTorque can guide you—end to end. From design and build to maintenance and optimisation, we ensure your operation stays running.

🔗 Learn more about our slurry pump capabilities here:

Why Mine Slurry Pumps Are Essential multitorque.com.au

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au