Skid Pump Systems: The Custom-Built Powerhouse for Industrial Pumping 2025

When it comes to industrial fluid management, there’s one piece of gear that stands out for reliability, transportability, and raw power: the skid pump. Built to handle aggressive applications—from mine dewatering to chemical transfer—skid-mounted pump systems offer rugged, mobile solutions that perform in the harshest environments.

At MultiTorque, we’ve been designing, supplying, and servicing skid pump systems across Australia for over 15 years. Whether you need a diesel-driven dewatering unit or a complete electric pump skid with custom automation, we build systems that work where others fail.

🔍 What Is a Skid Pump?

A skid pump is a complete pumping unit mounted on a skid base—typically a steel frame designed for easy transport and stability. The system may include:

- The pump itself (centrifugal, progressive cavity, gear, diaphragm, etc.)

- Drive system (diesel engine, electric motor, or hydraulic drive)

- Base skid frame with lifting lugs or forklift pockets

- Optional features like hose reels, control panels, valves, and fluid tanks

Skid pump systems are popular in industries where mobility and durability are essential. MultiTorque custom-builds these units to meet site-specific requirements, environmental standards, and operator preferences.

🛠️ Common Applications of Skid Pumps

We’ve seen skid pump systems used across virtually every major industrial sector. Some of the most common use cases include:

⛏️ Mining & Quarrying

- Mine dewatering

- Slurry and tailings transfer

- Diesel-powered skids for remote operations

🛢️ Oil & Gas

- Chemical injection skids

- Transfer of hydrocarbons or drilling fluids

- Explosion-proof electric pump skids

🚧 Civil Construction

- Bypass pumping for sewer and stormwater

- Emergency dewatering

- Jetting and flushing skids

🚜 Agriculture & Irrigation

- Fertigation or chemical dosing

- Large-volume water supply

- Portable irrigation pump skids

🏭 Industrial & Manufacturing

- High-pressure wash-down skids

- Process fluid transfer

- Tank and chemical blending stations

🔧 Key Features of MultiTorque Skid Pump Systems

At MultiTorque, we don’t just supply pumps—we engineer fully integrated systems designed to handle your specific workload. Here’s what sets our skid pump solutions apart:

✅ 1. Custom-Built to Spec

Every skid is designed based on:

- Fluid type

- Flow rate and pressure requirements

- Power availability (diesel, electric, hydraulic)

- Environmental or safety standards

If you need a low-shear progressive cavity skid for thick sludge or a high-volume centrifugal unit for stormwater, we can build it.

✅ 2. Rugged Frames and Mounting

Our steel skid bases are built to handle real-world work environments. We offer:

- Galvanised, painted, or stainless steel options

- Built-in lifting lugs

- Forklift access for easy transport

- Optional wheel kits for towable skids

✅ 3. Pump & Drive Flexibility

We work with leading pump brands like:

- Wilden

- Orbit

- NOV

- Napco

- Tuthill

And we pair them with drives from: - Kubota, Yanmar, or Perkins (diesel)

- ABB or TECO motors (electric)

✅ 4. Onboard Control & Monitoring

We offer:

- Starter panels

- VSDs (Variable Speed Drives)

- Flow meters and pressure gauges

- Remote monitoring and telemetry options

Need a plug-and-play unit with PLC automation? We’ve got you covered.

✅ 5. Ready for Harsh Environments

Our pump skids are built for:

- Mining dust and vibration

- Chemical resistance

- Extreme heat or cold

- Corrosive environments (marine or chemical sectors)

🔄 Pump Skid Servicing, Upgrades & Retrofits

Already have a skid pump but need an upgrade? MultiTorque offers:

- Full skid refurbishments

- Pump replacements

- Engine swaps or VSD retrofits

- Hose and fitting replacements

- Control panel upgrades

We can breathe new life into old gear and extend your pump investment with minimal downtime.

🧪 Skid Pump Fluid Compatibility

We build skids to handle:

- Water and wastewater

- Sludge and slurry

- Diesel, oil, and fuel blends

- Caustic and acidic chemicals

- Food-grade liquids (on request)

- Fertilisers and pesticides

Not sure what materials you need? We’ll help you select pump internals and seals that suit your application perfectly.

🛒 Why Choose MultiTorque for Skid Pump Systems?

At MultiTorque, we’ve earned a reputation for building high-performance, low-hassle pumping systems for Australia’s most demanding worksites. Here’s why clients choose us:

✅ 15+ Years of Industry Experience

We know your pressures, flow rates, environmental regs, and deadlines—we’ve been doing this for over a decade across mining, ag, oil & gas, and civil.

✅ Custom-Engineered Solutions

We don’t sell cookie-cutter gear. Every unit we build is designed around your specs and operating conditions.

✅ End-to-End Support

From pump selection and skid fabrication to on-site commissioning and training—our team supports you every step of the way.

✅ Local Expertise, National Reach

We’re proudly Australian-owned with operations in Perth and Brisbane, and we ship and service nationwide.

✅ Repairs, Spares & Servicing

Need urgent pump parts or a service tech on site? Call us—we offer fast turnaround on spares, hose replacements, and diagnostics.

🔗 Internal & Social Links

👉 Explore our full range of industrial pump systems and services at:

🌐 www.multitorque.com.au

👉 Connect with us on LinkedIn for updates, builds, and client wins:

🔗 MultiTorque on LinkedIn

🧠 Things to Consider When Specifying a Skid Pump

When planning your next pump skid, consider:

- What fluid are you pumping?

- Required flow rate and pressure?

- Power availability on site?

- Mobility requirements (forkliftable, towable)?

- Compliance standards (e.g., MSHA, AS4024)?

Our team will guide you through all of this and help design a system that’s built for performance and reliability.

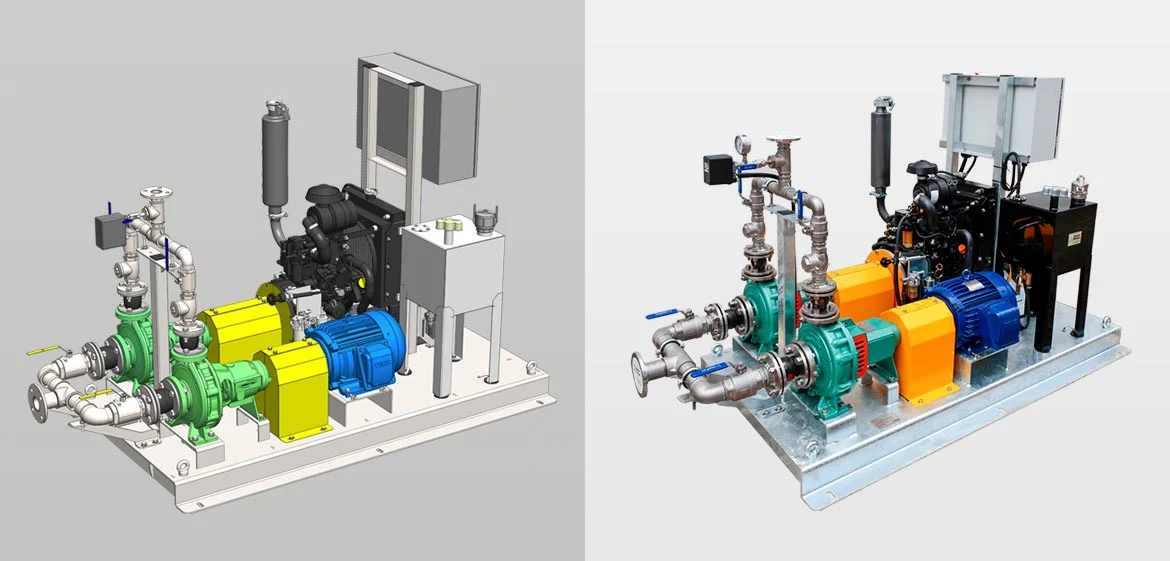

📸 Custom Projects: Real-World Builds by MultiTorque

Some of our recent projects include:

- ✅ Diesel-driven mine dewatering skid with heavy-duty Orbit pump and custom trailer

- ✅ Electric chemical transfer skid with NOV progressive cavity pump and stainless steel frame

- ✅ Skid-mounted air motor starter station integrated with a Wilden pump for explosive environments

Want to see more? Follow us on LinkedIn to view completed builds and behind-the-scenes shop footage.

📞 Get a Custom Skid Pump System Built for Your Operation

If you need a pump skid that won’t quit—no matter the mud, the mess, or the mileage—MultiTorque is your solution. Whether it’s mining, civil, ag, or chemical handling, we’ll spec, build, and deliver exactly what you need.

📍 MultiTorque

📞 1300 726 525

📧 sales@multitorque.com

👉 Visit us online: www.multitorque.com.au

👉 Follow us on LinkedIn: MultiTorque on LinkedIn