Seepex Pump Solutions for Industrial Applications: Quality You Can Trust 2025

Seepex is a globally recognized name in the pump industry, particularly known for its innovative progressive cavity pump designs. At MultiTorque, we’re proud to supply and support Seepex pump solutions for a wide range of industries across Australia. Whether you’re in mining, wastewater treatment, food processing, or chemical manufacturing, Seepex pumps offer the precision, reliability, and efficiency you need.

In this article, we’ll break down the benefits of Seepex pumps, common models and applications, maintenance tips, and why MultiTorque is your trusted partner for all Seepex pump requirements.

Contact MultiTorque

📍 Visit us online: www.multitorque.com.au

📧 Email: sales@multitorque.com

📞 Call us: 1300 726 525

🔗 Connect with us on LinkedIn

What Is a Seepex Pump?

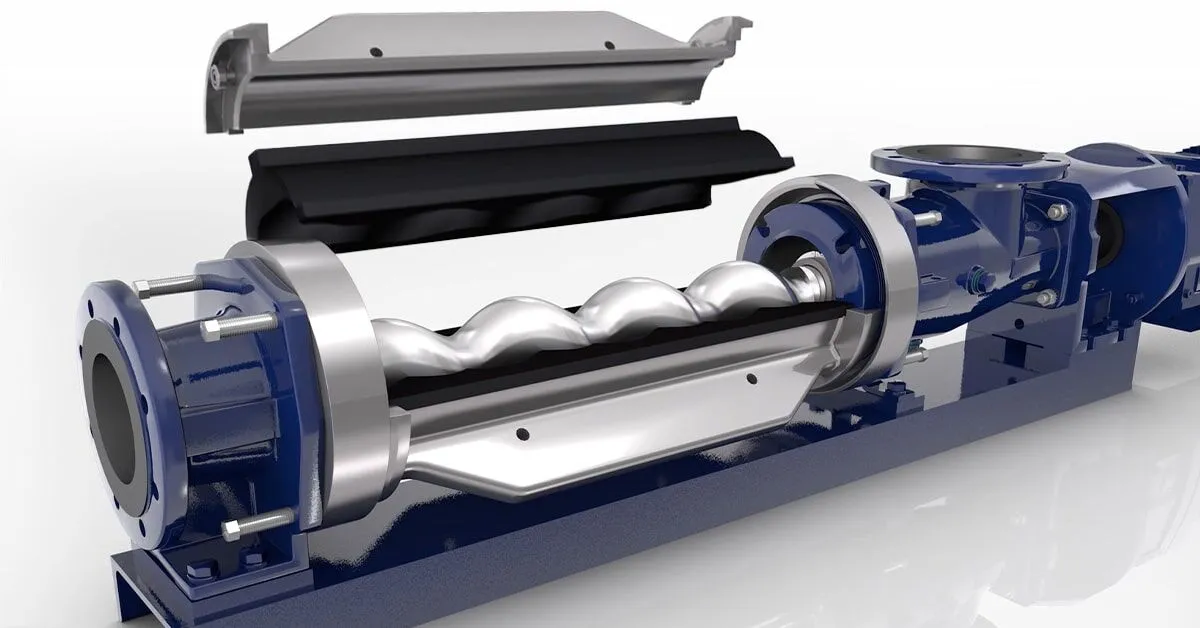

A Seepex pump is a type of progressive cavity pump, a positive displacement pump that moves fluids through a sequence of small, fixed-shaped cavities. These pumps are ideal for handling high-viscosity fluids, abrasive slurries, and sensitive media that require minimal pulsation and shear.

Seepex pumps are engineered with German precision, and their modular design allows for easy servicing, flexibility, and customization based on industry-specific needs.

Key Advantages of Seepex Pumps

- Modular Design

The Seepex modular system enables users to replace individual components rather than the entire pump, reducing maintenance costs and downtime. - Low Pulsation Flow

Progressive cavity pumps like Seepex offer continuous, low-pulsation flow, making them ideal for dosing and metering applications. - Handles Viscous and Abrasive Fluids

From thick sludge to abrasive slurries, Seepex pumps handle challenging fluids without clogging or wear common in other pump types. - Energy Efficiency

The pump design allows for energy-efficient operation, saving on long-term power consumption across industrial processes. - Customization for Specific Industries

Seepex offers tailored solutions for the food, pharmaceutical, oil and gas, chemical, and wastewater sectors.

Common Seepex Pump Applications

- Wastewater Treatment Plants: For sludge transfer and dewatering.

- Mining and Mineral Processing: For abrasive slurry handling.

- Food and Beverage: For sanitary-grade fluid transfer.

- Chemical and Petrochemical: For precise dosing of hazardous chemicals.

- Agriculture and Irrigation: For nutrient-rich slurry transfer.

Top Seepex Pump Models

- BN Range – General-purpose progressive cavity pumps.

- MD Range – Metering pumps designed for precision dosing.

- BTEX Range – Hopper-style pumps for viscous and non-flowable media.

- SCT (Smart Conveying Technology) – Innovative design for easy rotor/stator maintenance without dismantling pipelines.

Each of these models can be customized with different materials of construction, rotor/stator geometries, and drive options.

Maintenance Tips for Seepex Pumps

Maintaining a Seepex pump ensures a longer lifespan and reduces unscheduled downtime. Here are some tips from the MultiTorque workshop:

- Routine Inspection: Regularly check for signs of wear on the rotor and stator.

- Lubrication: Ensure that bearings and seals are adequately lubricated to avoid dry run failures.

- Spare Parts: Always keep key spare parts like stators, rotors, and seals on hand for rapid repair.

- Proper Cleaning: For food-grade models, follow CIP (clean-in-place) protocols to meet hygiene requirements.

- Monitor Flow Rates: Unexpected drops in flow could signal internal wear or blockage.

MultiTorque offers full workshop servicing for all Seepex pump models at our Queensland and Perth locations.

Why Buy Seepex Pumps from MultiTorque?

At MultiTorque, we don’t just sell pumps—we supply peace of mind. Here’s why more industries across Australia choose us:

- Local Stock: We source and stock Seepex pumps and genuine parts locally, reducing lead times.

- Expert Support: Our team understands the unique challenges of each industry and helps you select the right Seepex pump for the job.

- Custom Solutions: Need a skid-mounted or trailer-mounted Seepex pump unit? We custom-build solutions for your specific application.

- Workshops in Perth and Brisbane: In-house repair and servicing of all Seepex pumps—no third parties.

- Long-Term Relationships: We’ve built our name on trust, reliability, and ongoing support—not just one-time sales.

Industry Standards and Quality

Seepex pumps are manufactured to meet global quality standards such as ISO 9001, ATEX certification for explosive atmospheres, and 3A sanitary standards for food and pharma applications. That makes them not only efficient but also compliant with industry safety and regulatory requirements.

Aftermarket Parts and Upgrades

MultiTorque can supply both OEM Seepex parts and high-quality aftermarket alternatives. We also offer upgrades such as:

- Smart Conveying Technology (SCT) kits.

- Seal conversions for difficult applications.

- Energy-efficient motors to reduce operating costs.

- Custom pump packages with VFDs and pressure sensors.

Need help identifying your Seepex pump model? Contact our team today for a free assessment and quote.

Final Thoughts

If you’re searching for a reliable and efficient progressive cavity pump, a Seepex pump is an excellent choice. At MultiTorque, we bring you the best of both worlds—German engineering backed by local Australian service.

Whether you’re upgrading an existing system or sourcing a brand-new pump package, our team is here to help you select the right Seepex pump, provide servicing, and supply all required components.

Get in touch with MultiTorque today to talk about your Seepex pump requirements.

Contact MultiTorque

📍 Visit us online: www.multitorque.com.au

📧 Email: sales@multitorque.com

📞 Call us: 1300 726 525

🔗 Connect with us on LinkedIn