Sanitary Rotary Lobe Pump: Hygienic, Reliable, and Built for Clean Processing 2025

In industries where hygiene and contamination control are critical, equipment must meet the highest standards of cleanliness without sacrificing performance. The sanitary rotary lobe pump is a leading choice for food, beverage, dairy, cosmetics, and pharmaceutical operations due to its clean-in-place (CIP) capability, gentle fluid handling, and stainless-steel construction.

At MultiTorque, we supply and support sanitary rotary lobe pumps across Australia, delivering precision-engineered systems built to comply with strict hygiene standards and withstand the rigours of daily operation. Whether you’re processing yoghurt, pumping lotions, or filling bottles with syrup, we’ve got the gear and know-how to keep your line flowing.

🔗 Visit MultiTorque Homepage

🔗 Follow MultiTorque on LinkedIn

What Is a Sanitary Rotary Lobe Pump?

A sanitary rotary lobe pump is a type of positive displacement pump designed specifically for hygienic applications. It operates by rotating two synchronized lobes inside a housing, creating sealed cavities that move fluid smoothly from the inlet to the outlet.

What makes it “sanitary” is the clean-friendly design—polished stainless steel surfaces, no dead zones, CIP/SIP capability, and compliance with standards like 3A, EHEDG, and FDA.

These pumps are ideal for environments where cross-contamination must be avoided, and where the product’s integrity must be preserved during transfer.

Key Features and Benefits

✅ Hygienic Design

- 316L stainless steel construction

- Polished internal surfaces to Ra < 0.8μm

- Tri-clamp or DIN sanitary fittings

- No crevices or dead zones that trap bacteria

✅ Clean-in-Place (CIP) & Steam-in-Place (SIP)

Sanitary rotary lobe pumps can be cleaned and sterilized without dismantling, saving time and maintaining compliance with hygiene standards.

✅ Gentle Fluid Handling

Minimal shear makes these pumps ideal for delicate fluids like cream, cheese curds, and emulsions.

✅ Versatile Flow Rates

Capable of dosing low volumes or moving high-viscosity products in bulk, with options for variable frequency drives (VFDs).

✅ Reversible Operation

Can run forward or reverse without damaging product integrity—perfect for filling, emptying, or flushing lines.

Industries That Use Sanitary Rotary Lobe Pumps

MultiTorque supplies sanitary lobe pumps to a wide variety of process-critical, contamination-sensitive sectors:

- Food & Beverage – Dairy, sauces, syrup, chocolate, and wine

- Dairy Processing – Milk, cream, yoghurt, cheese curd, and whey

- Pharmaceutical – Liquid medicines, ointments, creams, and gels

- Cosmetics & Personal Care – Lotions, shampoos, conditioners, and serums

- Brewery & Distillery – Yeast slurries, malt extract, and tank transfers

- Plant-Based & Vegan Products – Nut milk, plant-based creams, and vegan sauces

Wherever hygiene meets heavy-duty pumping, rotary lobe pumps deliver smooth, reliable results.

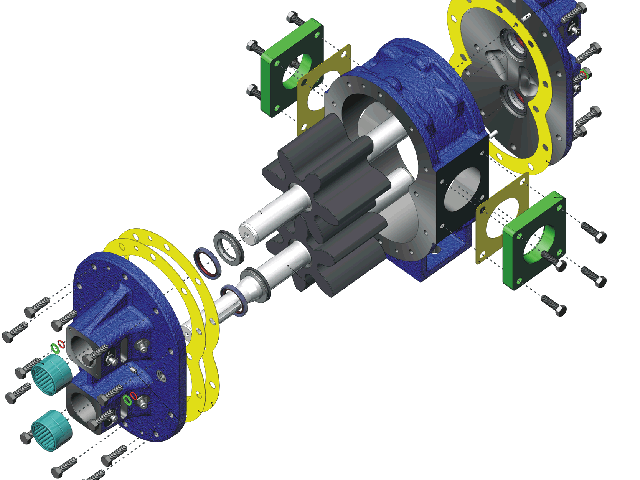

Components of a Sanitary Lobe Pump

Understanding the key components helps you maintain performance and identify replacement parts:

- Lobes – Bi-wing, tri-lobe, or multi-lobe configurations designed for gentle product movement

- Pump Casing – Constructed from 316L stainless steel, often electro-polished

- Seal Systems – Single or double mechanical seals made from hygienic materials

- Ports – Tri-clamp, SMS, DIN, or RJT connections for easy line integration

- Gearbox & Motor – Designed for low-speed operation with torque control

MultiTorque provides full support on parts, rebuilds, and custom configurations.

Sanitary vs. Industrial Rotary Lobe Pumps

While both pump types share a common operating principle, sanitary rotary lobe pumps are engineered for hygiene, washdown environments, and contamination prevention. Here’s how they differ:

| Feature | Industrial Lobe Pump | Sanitary Lobe Pump |

|---|---|---|

| Materials | Cast iron / SS304 | 316L stainless steel |

| Internal Surface Finish | Unpolished or rough | Mirror-polished |

| CIP/SIP Compatibility | Often no | Standard |

| Regulatory Compliance | None | 3A, EHEDG, FDA |

| Applications | Oil, slurry, wastewater | Food, pharma, cosmetics |

If you’re processing consumable or skin-contact products, sanitary is the only safe choice.

Custom Systems and Trailer Builds

At MultiTorque, we do more than just supply pumps—we build fully integrated pump skid systems and mobile pump trailers that are hygienic, efficient, and site-ready. Our builds include:

- Stainless steel frames and piping

- VFDs, flow meters, and control panels

- Cleanable drain pans and catch trays

- CIP lines and bypass systems

- Quick-disconnect tri-clamp fittings

Whether you need a compact dosing system or a full mobile production unit, we can engineer it to suit your operation.

Servicing, Parts, and Support

Hygienic processes rely on properly maintained pumps. MultiTorque offers:

- Seal replacements

- Lobe and casing repairs

- Pump strip-downs and rebuilds

- On-site service for food/pharma facilities

- Genuine and compatible spare parts

We support leading brands such as Fristam, Alfa Laval, Waukesha, and Ampco, and we can supply OEM or high-quality alternatives to suit your budget and lead time.

Why Choose MultiTorque?

- 🛠️ Over 15 years supplying rotary lobe pumps across Australia

- ✅ Hygiene-compliant pumps ready for dairy, pharma, and food processing

- 🚛 Fast delivery to Perth, Brisbane, and regional sites

- 🧪 Expertise in product compatibility and sanitary standards

- 💡 Custom pump packages, built to spec

- 🧰 Dedicated service teams for planned and emergency maintenance

How to Get Started

Want a hygienic pump that protects your product and meets your compliance needs? Let MultiTorque handle it.

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 LinkedIn: Follow MultiTorque Industries

We’ll guide you through selection, sizing, materials, and configuration.

Final Thoughts

A sanitary rotary lobe pump is the gold standard for clean, gentle, and efficient fluid transfer in hygiene-critical industries. Whether you’re dosing enzymes into a dairy line or transferring lotions in a cosmetics facility, the right pump ensures safety, compliance, and consistent performance.

At MultiTorque, we deliver more than pumps—we deliver tailored, end-to-end fluid handling solutions with expert support, genuine parts, and custom systems designed for your application.