Rotary Lobe Pump: A Powerful Solution for Viscous Fluid Handling 2025

When it comes to moving high-viscosity, shear-sensitive, or solid-laden fluids, few technologies perform as efficiently and reliably as the rotary lobe pump. Known for their gentle product handling, robust design, and sanitary capabilities, rotary lobe pumps are widely used across industries ranging from food and beverage to wastewater treatment and pharmaceuticals.

At MultiTorque, we supply, service, and support rotary lobe pump systems across Australia, offering both standard units and fully custom builds. Whether you’re pumping cream, sludge, or chemicals, our team can help you choose the right solution and keep it running smoothly.

🔗 Visit MultiTorque Homepage

🔗 Follow us on LinkedIn

What Is a Rotary Lobe Pump?

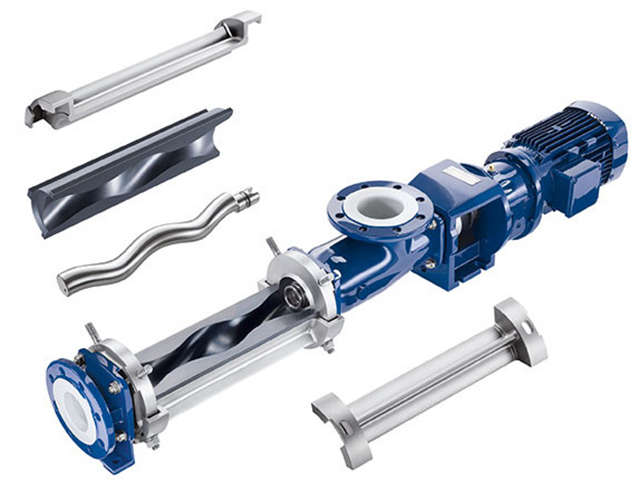

A rotary lobe pump is a type of positive displacement pump that moves fluid using rotating lobes inside a casing. As the lobes rotate, they form cavities that trap and move fluid from the inlet to the outlet. These pumps can handle a wide range of viscosities and are highly effective for fluids that contain soft solids or require gentle handling.

Because the lobes do not touch each other or the pump casing, they offer low shear, minimal pulsation, and high durability. Their hygienic design also makes them a top choice for clean-in-place (CIP) systems in food and pharmaceutical applications.

Key Benefits of Rotary Lobe Pumps

✅ Gentle Fluid Handling

Perfect for shear-sensitive products like yoghurt, creams, or pharmaceutical slurries. They maintain product integrity while ensuring smooth, uninterrupted flow.

✅ Bi-Directional Operation

Rotary lobe pumps can run in both directions, allowing for simple system design and easy cleaning or flow reversal.

✅ Solids Handling

Capable of pumping fluids with soft solids without damaging the media or the pump itself.

✅ Hygienic and Sanitary Design

Models with stainless steel construction and CIP/SIP capability meet strict hygiene standards for food, beverage, and pharmaceutical use.

✅ Consistent Flow Rates

Delivers accurate, pulse-free flow that supports dosing, metering, and steady pressure in pipelines.

Common Applications of Rotary Lobe Pumps

At MultiTorque, we supply rotary lobe pumps to a wide variety of industries:

- Food & Beverage – Dairy, syrups, sauces, jams, and beverages

- Wastewater Treatment – Sludge transfer and chemical dosing

- Pharmaceutical – Creams, gels, suspensions, and sterile media

- Chemical Processing – Resins, acids, polymers, and emulsions

- Oil & Gas – Crude oil, drilling mud, and additives

- Cosmetics & Personal Care – Lotions, pastes, shampoos

Wherever fluids need to be moved cleanly, gently, and reliably, rotary lobe pumps deliver results.

Materials and Configurations Available

Rotary lobe pumps are available in a wide range of materials and configurations to suit your specific application:

- Pump Housing: Stainless steel, cast iron, or high-grade alloys

- Lobes: Bi-wing, tri-lobe, or multi-lobe configurations, in stainless steel or elastomer-coated versions

- Seals: Mechanical, lip, or hygienic double seals

- Ports: Threaded, flanged, or tri-clamp sanitary fittings

We’ll help you select the right model based on pressure, viscosity, temperature, and chemical compatibility.

MultiTorque: Your Rotary Lobe Pump Experts

At MultiTorque, we specialise in supplying and supporting rotary lobe pump systems across Australia. With over 15 years of experience, we understand what’s needed to keep your operation running efficiently—whether you’re dosing food-grade fluids or managing thick sludges in harsh conditions.

Our Rotary Lobe Pump Services Include:

- Supply of new rotary lobe pumps from trusted brands

- Genuine and aftermarket spare parts

- On-site servicing and repairs

- Custom skid systems and trailer builds

- Technical consultation and system audits

We’ve worked with food processors, treatment plants, mines, and manufacturers to deliver robust, long-lasting pumping solutions tailored to their needs.

Rotary Lobe Pump vs Other Pump Types

Rotary Lobe Pump vs Centrifugal Pump

Centrifugal pumps struggle with viscous or shear-sensitive fluids, whereas rotary lobe pumps shine in these conditions.

Rotary Lobe Pump vs Peristaltic Pump

Peristaltic pumps are great for gentle pumping, but rotary lobe pumps offer higher flow rates, better solids handling, and lower maintenance in many cases.

Rotary Lobe Pump vs Progressive Cavity Pump

PC pumps can handle similar fluids but may be more prone to wear in abrasive applications. Rotary lobe pumps often last longer with lower maintenance requirements.

Each application is different — and at MultiTorque, we’ll help you choose the right solution, even if it isn’t a rotary lobe pump.

Custom Skid Packages and Turnkey Systems

Need more than just a pump? We design and build custom pump skid systems that include:

- Rotary lobe pumps with drive motors and VFDs

- Inlet/outlet piping and valves

- Instrumentation and controls

- Base-mounted or trailer-mounted units

- Safety features and site-specific compliance

Our builds are engineered for safety, serviceability, and long-term durability, and are ideal for remote operations or high-risk environments.

Spare Parts and Maintenance

Rotary lobe pumps require periodic servicing to replace wear components like lobes, seals, and bearings. At MultiTorque, we stock and supply:

- Replacement lobes

- Seal kits

- Bearing assemblies

- Gearboxes and shafts

- Pump casing components

We offer both genuine OEM parts and cost-effective compatible parts for ongoing maintenance and emergency repairs.

How to Get Started

Whether you’re upgrading a current pump, building a new system, or replacing worn parts, MultiTorque is here to help.

📞 Call us on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 LinkedIn: Follow MultiTorque Industries

Tell us what you’re pumping, and we’ll design the right solution — fast, reliable, and built for your site.

Final Thoughts

The rotary lobe pump is a workhorse for modern industry — rugged, versatile, and perfect for handling thick, shear-sensitive fluids with care. Whether you’re in food production, wastewater, chemicals, or oil and gas, a properly specified rotary lobe pump will increase your system reliability, reduce maintenance, and protect your product quality.

At MultiTorque, we’re not just pump suppliers — we’re partners in keeping your systems flowing, your downtime minimal, and your results rock-solid.