Pump Impellers: Essential Components for Optimal Pump Performance 2025

When it comes to industrial pumping systems, the pump impeller is one of the most critical components. At MultiTorque, we supply, service, and repair high-quality impellers to ensure your pumps perform efficiently, safely, and reliably. With over 15 years of experience in the Australian pump industry, MultiTorque is a trusted partner for businesses across Perth, Brisbane, and nationwide.

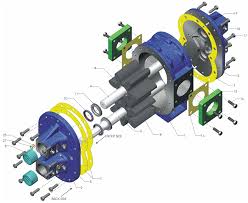

What is a Pump Impeller?

A pump impeller is the rotating part of a pump that transfers energy from the motor to the fluid being pumped. Impellers are responsible for generating flow and pressure, making them a key determinant of a pump’s efficiency. The design and material of an impeller directly influence:

- Flow rate and pressure output

- Efficiency and energy consumption

- Durability and resistance to wear or corrosion

- Suitability for specific fluids and environments

MultiTorque supplies impellers for a wide range of pumps, including centrifugal pumps, diaphragm pumps, progressive cavity pumps, and other positive displacement pumps.

Types of Pump Impellers

Pump impellers can be classified based on design and application:

- Open Impellers

- Simple design, easy to clean

- Suitable for fluids with low solids content

- Closed Impellers

- Contains front and back shrouds for increased efficiency

- Ideal for high-pressure applications and clear liquids

- Semi-Open Impellers

- Combines features of open and closed designs

- Suitable for handling fluids with some solids

- Specialty Impellers

- Designed for specific industrial applications, such as Wilden pump parts or Yamada air pump systems

- Optimized for chemical resistance, abrasive fluids, or high-temperature conditions

Why Quality Pump Impellers Matter

Selecting the right pump impeller supplier is critical for maintaining pump performance and longevity. Poor-quality or incompatible impellers can lead to:

- Reduced flow efficiency and higher energy consumption

- Premature wear of pump components

- Increased maintenance costs

- Unexpected downtime in industrial operations

At MultiTorque, we ensure every impeller is precision-engineered and tested to meet rigorous quality standards, helping you avoid costly failures and operational interruptions.

MultiTorque’s Impeller Solutions

- Extensive Range of Impellers

We stock impellers for a variety of pump brands and models, ensuring compatibility with systems such as Wilden M8 pumps, Dayton diaphragm pumps, and Nov Mono Pumps. - Custom Impeller Fabrication

For unique or specialized industrial applications, MultiTorque can design and manufacture custom impellers. Our engineering team works with clients to optimize impeller performance for challenging fluids, pressure requirements, and operational conditions. - Repair and Servicing

MultiTorque provides full in-house impeller repairs and maintenance, restoring worn or damaged impellers to peak performance. Our workshops use advanced tools and techniques to extend the life of your pump components. - Expert Technical Support

Our team provides guidance on selecting the correct impeller design, materials, and size for your specific pump system. Whether you are replacing an existing impeller or designing a new installation, MultiTorque offers expert advice and technical support.

Industries That Rely on High-Quality Impellers

Pump impellers are essential across many industrial sectors:

- Mining: Dewatering, slurry transport, and chemical handling require impellers that can withstand abrasive and corrosive conditions.

- Oil and Gas: Pumps in this sector demand impellers resistant to chemicals, high pressure, and extreme environments. MultiTorque supports applications like submersible pump oil and gas operations.

- Food and Beverage: Hygienic impellers are critical in processes like brewing, dairy, and beverage production. Explore our diaphragm pump solutions for brewing.

- Water and Wastewater: Impellers in municipal and industrial water systems ensure reliable flow and treatment processes.

Choosing the Right Pump Impeller Supplier

When sourcing impellers, consider the following:

- Compatibility: Ensure the impeller fits your specific pump make and model.

- Material Quality: Choose impellers made from durable metals or polymers suitable for your fluid type.

- Design Efficiency: The right design improves flow rates, reduces energy costs, and prevents wear.

- Support and Expertise: A supplier should provide guidance, technical support, and servicing options.

- Delivery and Availability: Reliable suppliers maintain stock and offer fast delivery to minimize downtime.

MultiTorque satisfies all these criteria, making us a leading choice for pump impellers across Australia.

Why Partner with MultiTorque

Partnering with MultiTorque means you get:

- High-Quality Components: Precision-engineered impellers for peak performance

- Comprehensive Services: Repair, maintenance, and technical support

- Custom Solutions: Tailored impellers for unique industrial applications

- Nationwide Access: Serving Perth, Brisbane, and all of Australia

- Trusted Industry Expertise: Over 15 years of experience supplying, servicing, and repairing pumps

Get in Touch with MultiTorque

For businesses looking for reliable pump impellers, MultiTorque is your trusted partner. Explore our full range of pump solutions and services by visiting our homepage or connect with us via LinkedIn. Our team is ready to help you choose the right impeller and ensure your pumps operate at peak efficiency.

Conclusion

Pump impellers are vital for maintaining flow, pressure, and efficiency in industrial pumps. Choosing the right supplier and quality components is crucial to reduce maintenance costs, prevent downtime, and extend pump lifespan. MultiTorque offers a comprehensive range of impellers, repair services, and technical support, making us a trusted partner for Australian industries seeking reliable pump solutions.