Pump Impeller Repair Services Across Australia | MultiTorque Experts in Precision Repairs 2025

The impeller is the heart of any pump system—spinning, pressurizing, and pushing fluid where it needs to go. But over time, even the toughest impellers wear down due to cavitation, erosion, or corrosion. When that happens, your pump loses efficiency, and downtime becomes a costly problem.

That’s where pump impeller repair comes in. At MultiTorque, we specialize in precise impeller repairs for centrifugal and positive displacement pumps, helping Australian industries get back to peak performance without the cost of full replacement.

Why Impeller Repairs Are Critical

The impeller is constantly exposed to aggressive conditions—abrasive slurries, corrosive chemicals, high-speed rotation, and pressure fluctuations. When damaged, an impeller can:

-

Lower pump flow and head pressure

-

Cause imbalance and vibration

-

Lead to motor or bearing failures

-

Increase energy consumption

-

Shorten pump lifespan

Timely impeller repairs restore your equipment’s performance and prevent more serious failures.

Common Impeller Damage We Repair

At MultiTorque, we repair and recondition impellers suffering from:

-

Cavitation pitting – caused by vapor bubbles imploding inside the pump

-

Erosion wear – from abrasive particles in water or slurry

-

Corrosion – especially in chemical or seawater environments

-

Bent or broken vanes – due to solids, debris, or mechanical stress

-

Imbalance – leading to noise, vibration, and seal wear

We use advanced diagnostic tools to inspect wear patterns and match the repair approach to your pump’s service conditions.

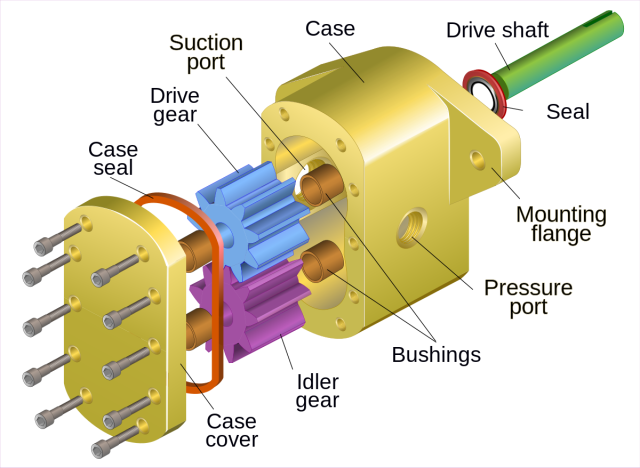

Our Pump Impeller Repair Process

We follow a thorough repair process to ensure long-lasting results:

-

Inspection & Testing

We assess wear, balance, and material condition before any repair begins. -

Surface Restoration

We weld, grind, and refinish worn vanes or impeller faces using appropriate alloys. -

Rebalancing

We use dynamic balancing machines to eliminate vibration and restore smooth rotation. -

Protective Coatings

We apply wear- or corrosion-resistant coatings to extend impeller life in tough environments. -

Final Testing

Each repaired impeller is inspected for tolerance and balance before reinstallation.

Servicing All Major Pump Brands

MultiTorque services impellers and pump components from all leading brands, including:

-

Wilden

-

Napco

-

Orbit

-

NOV

-

Grundfos

-

CAT Pumps

No matter the make or model, we’ve got the skills and equipment to bring it back to life.

Repair vs Replace: Why Repairing an Impeller Makes Sense

While impeller replacement is sometimes necessary, repairing a damaged impeller is often:

-

More cost-effective

-

Faster than ordering a new part

-

Customizable with better coatings or performance upgrades

-

More sustainable and environmentally friendly

We’ll advise you on the best solution based on cost, urgency, and expected performance.

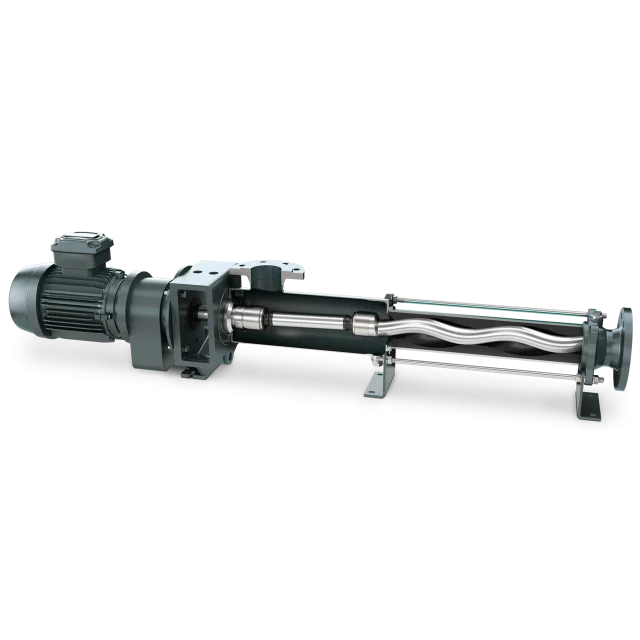

Pump Types We Work On

We provide impeller repairs for:

-

Centrifugal pumps

-

Slurry pumps

-

Water transfer pumps

-

Submersible pumps

-

Multistage and end-suction pumps

Our workshops in Perth and Brisbane are fully equipped, and we also offer on-site services across Australia.

Why Choose MultiTorque?

-

15+ years’ experience in industrial pump repairs

-

Fast turnaround with minimal downtime

-

Skilled technicians and in-house balancing equipment

-

Australian-owned and focused on long-term client relationships

-

Reliable support for mining, agriculture, oil & gas, and water treatment industries

Contact MultiTorque for Pump Impeller Repair

If your pump isn’t performing like it used to, it might be time to check the impeller. Call MultiTorque today to get it professionally assessed and repaired.

📞 1300 726 525

📧 sales@multitorque.com

🌐 www.multitorque.com.au

🔗 MultiTorque LinkedIn

MultiTorque — restoring impellers, reviving performance.