Pump Centrifugal Pump: 7 Powerful Reasons It Rules Industrial Flow in 2024

🚀 Pump Centrifugal Pump: 7 Powerful Reasons It Rules Industrial Flow in 2024

If you’re in the market for a high-performance fluid-moving solution, there’s one piece of gear that continues to dominate: the pump centrifugal pump. Whether you’re pumping clean water, slurry, chemicals, or wastewater, this pump is a proven winner in almost every sector.

At MultiTorque, we don’t just sell centrifugal pumps—we custom-engineer, manufacture, supply, and repair them to keep industries moving across Australia. Let’s break down exactly why a pump centrifugal pump is the weapon of choice for so many operations.

⚙️ 1. What Is a Pump Centrifugal Pump?

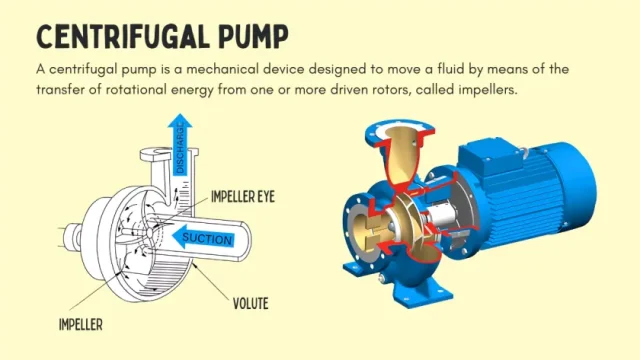

A pump centrifugal pump works by converting rotational energy—usually from an electric motor or diesel engine—into kinetic energy to move fluids. The liquid enters through the pump’s eye (inlet), is rapidly spun by the impeller, and exits under pressure through the discharge port.

It’s a design that’s been trusted for over 150 years, and in 2024, it’s still the go-to solution for high-volume, low-viscosity fluid transfer.

💡 2. MultiTorque = Custom-Built Centrifugal Power

Off-the-shelf pumps work for some—but if you’ve got unique flow rates, harsh conditions, or tough terrain, you need a custom-built centrifugal system.

We offer:

-

Skid-mounted units

-

Trailer-mounted pumps

-

Generator-powered or solar-powered options

-

Variable frequency drive (VFD) controls

-

Dual pump centrifugal pump setups for redundancy

If you can describe it, we can build it. That’s the MultiTorque advantage.

🔁 3. Dual-Stage Pump Centrifugal Pump Setups

The term “pump centrifugal pump” can refer to two-stage or booster pump setups, which use a second pump to increase total head or volume.

Dual-stage systems are used in:

-

Deep mine dewatering

-

Large-scale irrigation

-

Flood management

-

Industrial water processing

We engineer these systems in-house to meet exacting flow and lift requirements.

🌊 4. Impressive Flow Rates & Pressure

Expect flow rates from 50 LPM up to over 30,000 LPM with the right centrifugal pump setup. Total dynamic head can range from 10 to 150 metres depending on impeller size, rotation speed, and liquid characteristics.

Whether you’re dealing with clean water or abrasive slurry, our range of Napco, NOV, Wilden, and other trusted brands has you covered.

🧠 5. Simple Design, Massive Reliability

The beauty of a pump centrifugal pump lies in its simplicity. With fewer moving parts than positive displacement pumps, they’re:

-

Easier to maintain

-

Cheaper to service

-

More energy-efficient at higher volumes

That’s why they’re standard in water treatment plants, farms, and industrial facilities.

🛠️ 6. We Service What We Sell (and More)

MultiTorque offers full repair, replacement, and upgrade services for all types of centrifugal pumps—even ones we didn’t originally supply. This includes:

-

Seal replacements

-

Bearing rebuilds

-

Impeller upgrades

-

Motor testing

-

Performance optimisation

And yes—we can even turn your aging system into a fully mobile, generator-powered beast.

🌍 7. Industries That Rely on Pump Centrifugal Pumps

You’ll find our centrifugal pump systems working hard in:

-

Mining & Resources – Dewatering and slurry transfer

-

Construction – Flood control and groundwater management

-

Oil & Gas – Cooling and fluid transfer

-

Agriculture – Crop irrigation and dam pumping

-

Municipal Utilities – Sewer bypass and potable water pumping

In every case, these industries rely on the efficiency, durability, and scale of centrifugal technology.

🔧 Get the Right Centrifugal Pump—First Time, Every Time

At MultiTorque, we’re not just another supplier—we’re your industrial pump partner. Whether you need a standalone centrifugal pump, a dual-stage booster system, or a fully mobile pump truck, we deliver on performance, price, and support.

📞 Let’s Power Your Flow

Call us to get a quote or a custom solution:

📞 1300 726 525

📧 sales@multitorque.com.au

🌐 www.multitorque.com.au

🔗 Follow MultiTorque on LinkedIn