What Is a Progressive Screw Pump: Powerful uses and Expert Support 2025

A progressive screw pump, also known as a progressive cavity pump, is a type of positive displacement pump specifically designed to handle challenging fluids. From abrasive slurries to highly viscous substances, these pumps deliver steady, non-pulsating flow—making them essential for industries that require precision, reliability, and minimal shear.

At MultiTorque, we service, supply, and repair progressive screw pumps for a wide range of Australian industries, offering tailored solutions that stand the test of time. If you’re looking to boost performance, reduce downtime, or get a new pump installed, we’ve got you covered.

What Is a Progressive Screw Pump?

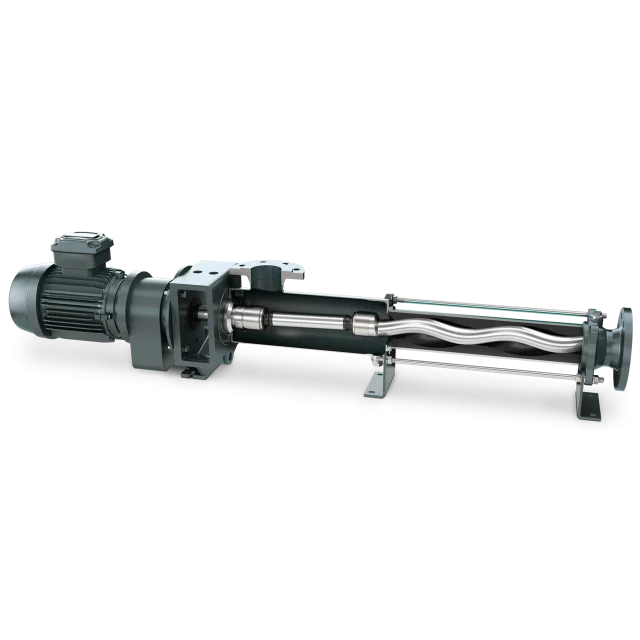

A progressive screw pump uses a single-helix rotor that turns inside a double-helix stator to move fluid in a progressive, chamber-by-chamber motion. As the rotor turns, the cavities shift from suction to discharge, transferring fluid without interruption. This design makes the pump ideal for transporting:

-

Viscous materials

-

Shear-sensitive fluids

-

Solids-laden slurries

-

Corrosive or abrasive liquids

Unlike centrifugal pumps, which rely on speed and momentum, a progressive screw pump provides consistent flow regardless of pressure or viscosity—perfect for tough, high-demand environments.

Key Benefits of a Progressive Screw Pump

1. Smooth and Pulsation-Free Flow

The continuous motion ensures stable flow rates, making it ideal for dosing, metering, and pressure-sensitive applications.

2. Self-Priming Capability

Progressive screw pumps can self-prime even in dry conditions, which is a major advantage for remote or intermittent flow operations.

3. Excellent for High-Viscosity and Solids-Laden Fluids

Whether you’re pumping sludge, slurry, molasses, or polymer emulsions, a progressive screw pump keeps things moving without clogging or excessive wear.

4. Low Shear Pumping

The gentle action preserves the integrity of shear-sensitive fluids like food products, biochemicals, and emulsions.

5. Reversible Flow

Changing the direction of the rotor allows for bi-directional flow, providing additional flexibility for system design or emergency operations.

Common Applications Across Industries

At MultiTorque, we support clients in:

-

Mining – Tailings, slurry, dewatering

-

Oil & Gas – Drilling fluids, well servicing

-

Agriculture – Manure pumping, irrigation additives

-

Food & Beverage – Viscous ingredients, fruit pulp

-

Chemical Processing – Polymers, acids, corrosives

-

Wastewater Treatment – Sludge, lime slurry, grit

Our technicians understand the unique needs of each sector and can help you select the right progressive screw pump for maximum efficiency.

Service, Repairs, and Spare Parts Australia-Wide

Progressive screw pumps are built tough, but like any equipment, they need proper maintenance. With locations in Perth and Brisbane, MultiTorque offers:

-

Preventative maintenance and breakdown repairs

-

Rotor and stator replacements

-

Mechanical seal and gasket servicing

-

On-site servicing and trailer-mounted systems

-

Spare parts for leading brands (Netzsch, Mono, Orbit, and more)

Don’t settle for generic servicing—our team specialises in industrial pumping systems, and we back every repair with unmatched product knowledge.

Custom Solutions for Unique Applications

MultiTorque doesn’t just supply pumps—we engineer complete systems. If you need a progressive screw pump mounted on a mobile skid or custom trailer, we can design and build a turnkey package to suit your site conditions. Whether you’re dealing with remote mine sites or off-grid ag applications, we’ll build a pump system that works when and where you need it most.

Call MultiTorque Today for Progressive Screw Pump Solutions

Ready to upgrade your pump system or need emergency service? Trust MultiTorque for expert support, reliable repairs, and quality components.

📞 Call us today on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au