Priming Pump: Essential for Reliable Pump Start-Up and Performance 2025

In any fluid transfer system, ensuring a pump is properly primed before startup is critical for efficient operation and to avoid costly damage. That’s where a priming pump comes into play. Whether you’re working with centrifugal pumps in dewatering, firefighting systems, industrial processing, or irrigation, a priming pump ensures your main pump has a full column of liquid before it runs.

At MultiTorque, we supply, service, and custom-build pump systems throughout Australia. Our team specialises in integrating priming solutions for a wide range of industries, helping clients reduce downtime and extend equipment life.

🔗 Visit MultiTorque Homepage

🔗 Follow MultiTorque on LinkedIn

What Is a Priming Pump?

A priming pump is a device used to remove air from the suction line and fill the pump casing with liquid before the main pump is started. This is particularly important for centrifugal pumps, which cannot generate suction lift without being primed.

Priming pumps can be manual, mechanical, or automated, depending on the system’s size, complexity, and application. Their goal is simple: ensure liquid reaches the pump impeller before rotation begins, preventing air binding, cavitation, or dry running.

Why Priming Matters

Priming isn’t just a procedural step—it’s an essential safeguard. Operating a pump without priming can lead to:

- Cavitation damage

- Impeller overheating

- Seal failure

- Flow disruption

- Pump burnout

A proper priming system is a must-have in installations where the fluid source is below the pump’s inlet or where suction lines are prone to air entrapment.

Common Applications for Priming Pumps

Priming pumps are used across multiple sectors, including:

- Construction & Dewatering – Removing groundwater and stormwater with portable diesel pump sets

- Agriculture & Irrigation – Drawing water from below-grade sources like bores, wells, or tanks

- Firefighting Systems – Ensuring quick startup in high-pressure fire pumps

- Industrial Processing – Starting transfer pumps where air gets trapped in suction lines

- Marine & HVAC – Maintaining suction on ballast, bilge, and circulation systems

- Sewage & Wastewater – Lifting fluids from pits, sumps, or underground tanks

MultiTorque offers integrated priming systems tailored to your site’s layout and process requirements.

Types of Priming Pumps and Systems

There’s no one-size-fits-all solution. We supply and install several types of priming systems depending on your pump type, elevation, and flow conditions:

✅ Self-Priming Pumps

These pumps are designed with a built-in reservoir that holds liquid for re-priming after each cycle. Ideal for intermittent operations and mobile units.

✅ Vacuum Priming Systems

A vacuum pump is connected to the suction line to evacuate air and draw fluid to the pump. Common in large-scale or automated systems.

✅ Compressor Priming

Uses air compressors and ejectors to displace air from the suction line. Often found in firefighting or high-capacity dewatering systems.

✅ Manual Priming

Operators fill the pump casing manually using hand pumps or fill valves. Suitable for small or low-cost systems.

✅ Foot Valve & Priming Chamber

A check valve at the suction line’s bottom retains fluid, maintaining prime between pump cycles.

Priming Pump vs. Self-Priming Pump

A priming pump is a separate accessory or subsystem that assists a standard pump (like a centrifugal pump) in achieving suction lift.

In contrast, a self-priming pump is specifically designed to retain enough liquid in its casing after shutdown to re-prime automatically on the next startup. While self-priming pumps are convenient, they have flow limitations and may not suit all fluids or solids.

MultiTorque supplies both options and can help determine which is right for your application.

Choosing the Right Priming Solution

When selecting a priming pump or system, consider the following:

- Suction lift height – How far below the pump is the fluid?

- Fluid type – Clean water, slurry, sewage, or chemicals?

- Pump size and capacity – Larger pumps often require vacuum-assisted priming.

- Frequency of start-up – Frequent starts require automated or self-priming options.

- System pressure and elevation – Affects air removal and fluid flow dynamics.

Our team will evaluate your system and recommend the most effective, maintenance-friendly option.

Custom Skid Systems with Priming Integration

At MultiTorque, we build complete pump skid systems and trailer-mounted units that include:

- Priming pumps

- Centrifugal or diaphragm main pumps

- VFDs and control panels

- Priming chambers or vacuum lines

- Flow and pressure sensors

- Bunded frames or enclosed trailers for site deployment

Whether you’re building a borehole dewatering unit or a mobile firefighting solution, our team can engineer a priming-integrated setup that runs safely and efficiently.

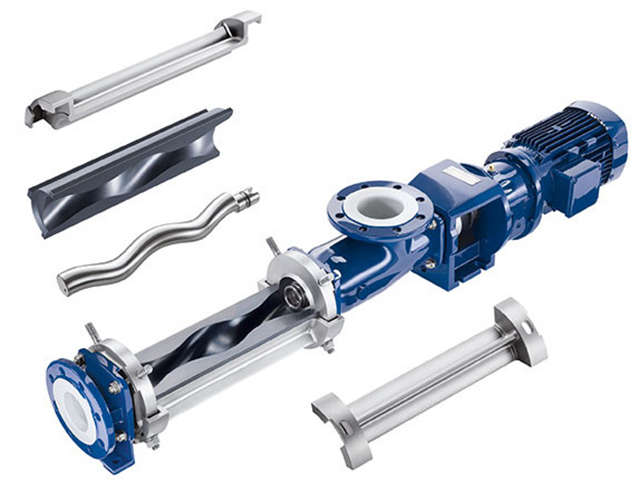

Maintenance and Spare Parts

Priming pumps—like any mechanical component—require routine checks to perform reliably. We offer:

- Spare vacuum pumps, valves, ejectors, and sensors

- Service kits for foot valves and priming tanks

- Seal and impeller replacements for self-priming units

- On-site troubleshooting and system inspections

- Retrofitting and automation upgrades for older systems

Our workshop teams in Perth and Brisbane can rapidly refurbish, test, and dispatch parts nationwide.

Why Choose MultiTorque?

- 🛠️ 15+ years supplying and servicing pumps across Australia

- 🔧 Custom-engineered solutions with priming systems included

- 🚚 Fast parts and mobile service support

- 🧠 Industry experience in mining, water, agriculture, and construction

- 🤝 Honest advice, proven results, and local expertise

We don’t just sell pumps—we design systems that work and keep your operations flowing.

Ready to Get Primed?

If you’re building or upgrading a pump system, make sure your priming solution is up to the job. Let MultiTorque help you design the right setup from day one—or improve an existing system for better reliability and ease of use.

📞 Call us today: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Follow us on LinkedIn: MultiTorque Industries

Final Thoughts

Whether you’re working with high-head dewatering systems or precision fluid handling in processing plants, a priming pump is the unsung hero of reliable pump performance. Without it, even the best centrifugal pump can run dry, cavitate, or fail prematurely.

At MultiTorque, we offer priming solutions backed by engineering insight, service support, and long-term reliability—because a well-primed system is a system that lasts.