Positive Displacement Chemical Pump: Precision, Power, and Reliability with MultiTorque 2025

When it comes to transferring aggressive, hazardous, or high-value fluids, accuracy and control are non-negotiable. That’s where a positive displacement chemical pump outperforms the rest. Engineered for precision dosing and safe handling of corrosive liquids, these pumps are essential across chemical processing, water treatment, mining, oil & gas, and manufacturing.

At MultiTorque, we specialise in supplying and servicing positive displacement chemical pumps across Australia. With decades of hands-on experience and a deep understanding of fluid handling challenges, we deliver pump systems that are reliable, efficient, and site-ready.

🔗 Visit MultiTorque Homepage

🔗 Follow MultiTorque on LinkedIn

What Is a Positive Displacement Chemical Pump?

A positive displacement chemical pump is a pump that moves a fixed volume of fluid through a sealed chamber with each cycle. Unlike centrifugal pumps, which rely on velocity and pressure, positive displacement pumps deliver a constant flow rate regardless of pressure variations, making them ideal for precise chemical dosing and transfer.

They can be rotary (gear, peristaltic, diaphragm, or screw) or reciprocating (piston, plunger, diaphragm) depending on the application.

Why Choose a Positive Displacement Pump for Chemicals?

Chemical handling isn’t just about moving fluid — it’s about doing it safely, accurately, and consistently. A positive displacement chemical pump excels in:

✅ Precise Dosing

Essential for chemical metering, pH balancing, or reagent injection where small deviations can have big consequences.

✅ Viscosity Tolerance

These pumps handle thin solvents and thick, sticky resins with equal efficiency.

✅ Corrosion Resistance

Available in chemically resistant materials like PTFE, Hastelloy, stainless steel, and engineered plastics.

✅ High Pressure Handling

Unlike centrifugal pumps, positive displacement models excel in high-pressure chemical delivery scenarios.

✅ Gentle Fluid Movement

Perfect for shear-sensitive liquids or compounds that degrade under high turbulence.

Applications of Positive Displacement Chemical Pumps

MultiTorque supplies chemical pumps across sectors where performance, safety, and compliance are mission-critical:

- Water & Wastewater Treatment – Dosing of chlorine, alum, polymers, and pH balancers

- Mining & Minerals – Reagent injection, slurry conditioning, and acid pumping

- Oil & Gas – Methanol, glycol, corrosion inhibitors, and surfactants

- Chemical Manufacturing – Handling of solvents, acids, alkalis, and additives

- Food & Beverage – CIP chemicals, flavourings, and preservatives

- Agriculture – Fertilisers, pesticides, and liquid nutrients

No matter the fluid — acidic, caustic, viscous, or volatile — we have a pump built to handle it.

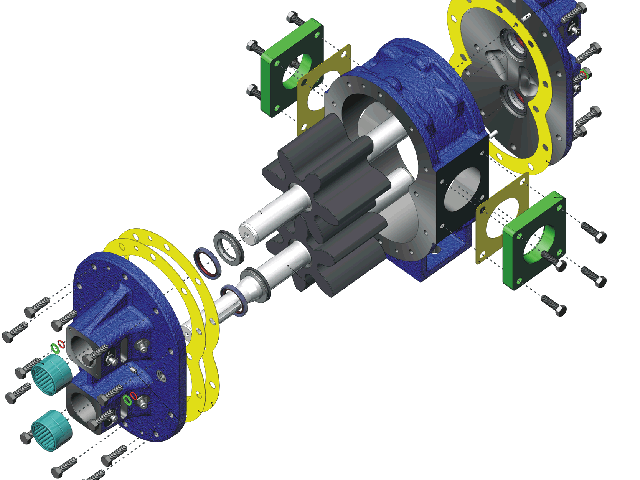

Types of Positive Displacement Chemical Pumps We Supply

At MultiTorque, we offer a wide range of chemical pumps to match your specific process needs:

🔄 Diaphragm Pumps

Air-operated double diaphragm (AODD) and mechanical diaphragm pumps are ideal for transferring corrosive and abrasive chemicals. Self-priming, dry-run capable, and explosion-proof options available.

🌀 Peristaltic Pumps

Perfect for low-shear chemical dosing and abrasive slurries. The fluid only contacts the tubing, making them excellent for sterile or aggressive fluids.

⚙️ Gear Pumps

Compact and reliable, gear pumps are suitable for high-pressure, low-viscosity chemical transfer with smooth, non-pulsing flow.

🧪 Progressive Cavity (PC) Pumps

Great for thick or solid-laden chemicals where flow consistency and pressure control are essential.

💧 Metering Pumps

Piston or diaphragm-driven pumps designed for extremely accurate dosing in lab or industrial scale processes.

Chemical Compatibility: Material Matters

Choosing the right chemical pump isn’t just about flow rate — it’s about matching the pump material to the media. We offer pumps in:

- Stainless Steel – General corrosion resistance

- PVDF / PTFE – Excellent for strong acids and oxidisers

- Hastelloy / Alloy 20 – For high-temperature, aggressive chemical environments

- Polypropylene – Lightweight, cost-effective chemical resistance

Not sure what materials suit your application? Our team will match the right pump body, elastomer, and seal configuration to your fluid — no guesswork involved.

Custom Pump Skids and Turnkey Systems

For industrial-scale dosing or transfer needs, we also build custom pump skid packages and trailer-mounted chemical pump systems. These systems are fully engineered and preassembled, ready for immediate site integration. Features include:

- Bunded containment for spill prevention

- Flow meters, sensors, and PLC integration

- Emergency stop and safety controls

- Compact layouts for tight spaces or remote sites

- Plug-and-play installation

Whether you’re dosing sulfuric acid into a mining circuit or metering flocculants at a treatment plant, MultiTorque delivers systems built for the job.

Service, Spare Parts & Maintenance

Chemical pumps endure some of the harshest operating conditions. We offer full aftermarket support, including:

- Spare Parts: Diaphragms, seals, valves, stators, rotors, and tubing

- Routine Maintenance: Pump strip-downs, chemical compatibility assessments

- Emergency Repairs: On-site diagnostics and rapid part replacement

- Upgrade & Retrofit Services: Modernise older pump systems with upgraded materials or automation

We support leading brands like Wilden, SEEPEX, Graco, Verder, and more — and also offer high-quality aftermarket alternatives when cost efficiency is a priority.

Why Choose MultiTorque?

- 🔧 15+ years of experience in fluid handling

- 🚛 National delivery across Perth, Brisbane, and regional Australia

- 🛠️ On-site service teams for emergency repairs

- 🧪 Chemical compatibility expertise

- 🧰 Custom systems built to your spec

- 💬 Straightforward advice and honest service

We’re not just suppliers — we’re solution builders. When your process depends on safe and accurate chemical delivery, MultiTorque is the name you can trust.

Ready to Order?

Let’s talk. Whether you need a replacement pump, a full chemical dosing system, or just help identifying a part — we’re here to help.

📞 Call us today: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Follow us on LinkedIn: MultiTorque Industries

Final Thoughts

When safety, accuracy, and durability matter, you need a positive displacement chemical pump built for the job — and a supplier that understands your application. MultiTorque offers the pumps, parts, service, and expertise to help Australian industry move chemicals with confidence.

No guessing. No shortcuts. Just engineered performance from a team that knows what you need — and how to deliver it.