Pneumatic Starter Diesel Engine: Reliable Starting Solutions for Heavy-Duty Applications 2025

In industries relying on heavy-duty diesel engines, dependable starting systems are essential. The pneumatic starter diesel engine system offers a safe, efficient, and durable method for igniting large diesel engines, especially in demanding environments like mining, marine, oil & gas, and power generation.

At MultiTorque, we specialize in supplying, servicing, and repairing pneumatic starters for diesel engines across Australia. With over 15 years of expertise, we ensure your equipment starts reliably, reducing downtime and maximizing operational efficiency.

What Is a Pneumatic Starter for Diesel Engines?

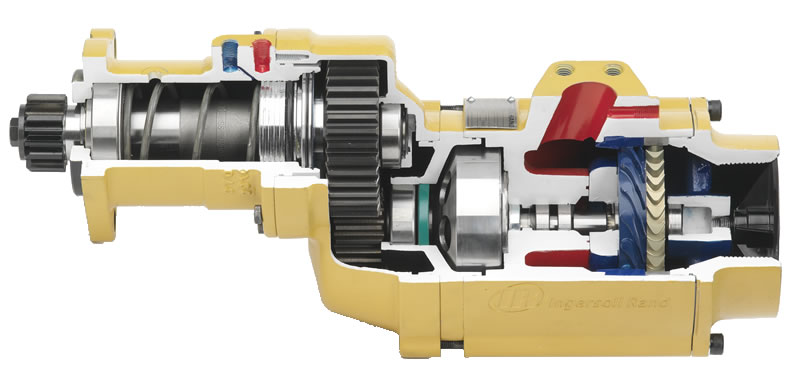

A pneumatic starter uses compressed air to crank a diesel engine, replacing traditional electric starters. It’s a motor powered entirely by compressed air, which spins a pinion gear that engages with the engine’s flywheel, turning the engine over until combustion begins.

This air-driven system is especially useful where electrical starters are unsafe or unreliable, such as explosive environments or remote sites without consistent electrical power.

How Does a Pneumatic Starter Work on a Diesel Engine?

The operation is straightforward and effective:

- Compressed air stored in tanks or generated by compressors is released into the pneumatic starter motor.

- The motor converts this air pressure into mechanical rotation.

- A pinion gear connected to the starter motor meshes with the diesel engine’s flywheel.

- The flywheel spins, cranking the engine to start.

- Once the engine fires up, the pinion retracts automatically.

Benefits of Pneumatic Starters for Diesel Engines

1. Enhanced Safety

No electrical sparks are generated, making pneumatic starters ideal for hazardous or explosive atmospheres common in oil refineries, gas plants, and mining sites.

2. Reliable Performance in Harsh Conditions

Pneumatic starters perform flawlessly in extreme temperatures, dust, moisture, and vibration — conditions that often cause electric starters to fail.

3. Minimal Maintenance

With fewer electrical parts, pneumatic starters require less upkeep, reducing maintenance costs and downtime.

4. Multiple Starting Attempts

Compressed air systems allow numerous start attempts without recharging, critical in emergency or remote operations.

5. High Starting Torque

They deliver powerful torque needed to start large diesel engines quickly, even in cold weather or under heavy load.

Typical Applications for Pneumatic Starters on Diesel Engines

- Mining haul trucks and machinery

- Offshore and marine diesel engines

- Oil & gas drilling rigs and generators

- Construction and agricultural equipment

- Emergency power backup systems

MultiTorque’s Expertise with Pneumatic Starters

For over 15 years, MultiTorque has been the trusted partner for companies requiring pneumatic starter diesel engine systems. We offer:

- Supply of new pneumatic starters compatible with all major diesel engine brands

- Comprehensive servicing and repair to extend equipment life

- Custom solutions and retrofits for older or specialized machinery

- Nationwide support with fast turnaround times

Our technicians understand the critical nature of reliable engine starting and work closely with clients to ensure optimal performance.

Maintenance Tips to Keep Your Pneumatic Starter in Top Shape

- Keep compressed air dry and free from contaminants to prevent motor damage.

- Regularly inspect and replace air filters.

- Lubricate starter components according to manufacturer specs.

- Check for leaks in air lines and fittings.

- Monitor pinion gear and engagement mechanisms for wear.

MultiTorque offers maintenance contracts to keep your pneumatic starters running smoothly and prevent costly failures.

Contact MultiTorque for Pneumatic Starter Diesel Engine Solutions

Need reliable pneumatic starters or expert repairs for your diesel engines? Contact MultiTorque today:

📞 Call 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries