NOV Mono Pump: Powerful Supplier Australia 2025

When it comes to pumping abrasive slurries, viscous fluids, or fragile materials, few technologies match the power and reliability of the NOV Mono Pump. Engineered for durability, precision, and long-term performance, these progressive cavity pumps are used worldwide across mining, wastewater, agriculture, and food processing industries.

At MultiTorque, we supply and service NOV Mono Pumps across Australia, with OEM-quality parts, custom builds, and expert support to keep your operation flowing—no matter how tough the job.

What Is a NOV Mono Pump?

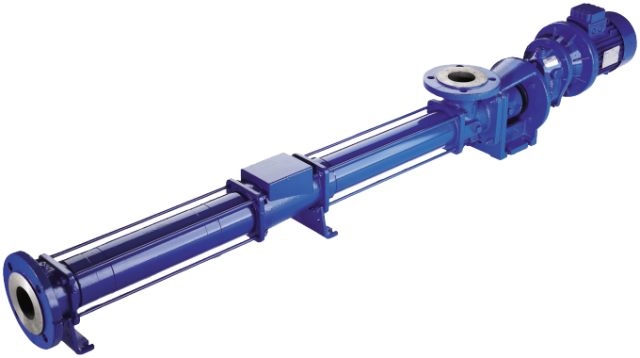

A NOV Mono Pump is a progressive cavity positive displacement pump designed by National Oilwell Varco (NOV), a global leader in industrial equipment. These pumps operate using a helical rotor that turns inside a resilient stator, creating sealed cavities that carry fluid with a steady, pulseless motion.

Unlike centrifugal pumps, Mono Pumps don’t rely on speed or pressure—they deliver precise flow control, even with thick or abrasive materials.

Key Features of NOV Mono Pumps

Heavy-Duty Design

Heavy-Duty Design

Made for rugged industrial use, Mono Pumps withstand high wear environments and harsh chemical exposure.

Smooth, Non-Pulsating Flow

Smooth, Non-Pulsating Flow

Ideal for dosing, feeding, or transferring sensitive or solid-laden fluids without damaging the product.

Self-Priming & Suction Lift Capabilities

Self-Priming & Suction Lift Capabilities

They can pump from below-ground sources such as pits, tanks, and sumps—making them perfect for dewatering and underground operations.

Low Shear Pumping

Low Shear Pumping

The gentle action protects fragile media like polymers, resins, or food products from mechanical damage.

High Viscosity & Solids Handling

High Viscosity & Solids Handling

From wastewater sludge to mineral tailings, Mono Pumps handle it all without clogging.

Industries That Rely on NOV Mono Pumps

Mining & Mineral Processing

Mining & Mineral Processing

Tailings transport

Chemical slurry transfer

Thickened sludge and slimes pumping

Wastewater Treatment

Wastewater Treatment

Digester feeds

Sludge handling

Dewatering transfer systems

Agriculture

Agriculture

Fertiliser injection

Effluent transfer

Molasses and feed pumping

Chemical & Industrial

Chemical & Industrial

Polymer dosing

Paints, adhesives, and emulsions

Abrasive or corrosive chemical handling

Food & Beverage

Food & Beverage

Pulp, paste, and syrup handling

Waste product transfer

Low-shear liquid movement

MultiTorque: Your Source for NOV Mono Pumps & Parts

At MultiTorque, we supply and service NOV Mono Pumps, including:

Pump repairs and full rebuilds

Rotor and stator replacements

Drive shaft and mechanical seal servicing

Custom trailer units with pump integration

In-house electrical panels tailored for Mono Pump systems

We stock key spares and components for Mono® and compatible pump lines, helping you avoid delays and stay operational.

Whether you need a small dosing pump or a heavy-duty sludge handler, our team can help spec, supply, install, or repair your Mono unit fast.

Why Trust MultiTorque?

We’ve been in the pumping game for over 15 years, supporting operations across Perth, Brisbane, and regional Australia. Our core values: Reliability, Safety, and No-Nonsense Service.

Deep technical knowledge of NOV Mono systems

Fully equipped workshop and mobile service vans

Licensed sparkies to wire up control systems

Fast dispatch of Mono-compatible parts

Custom-built mobile trailer units with Mono pumps onboard

Get a NOV Mono Pump Built for Your Job

If you’re dealing with thick sludge, high-viscosity fluids, or corrosive slurries, the NOV Mono Pump is a proven performer. Let MultiTorque help you upgrade your system with a reliable, long-lasting solution.