Mud Dewatering Pump Solutions Built for Tough Australian Conditions 2025

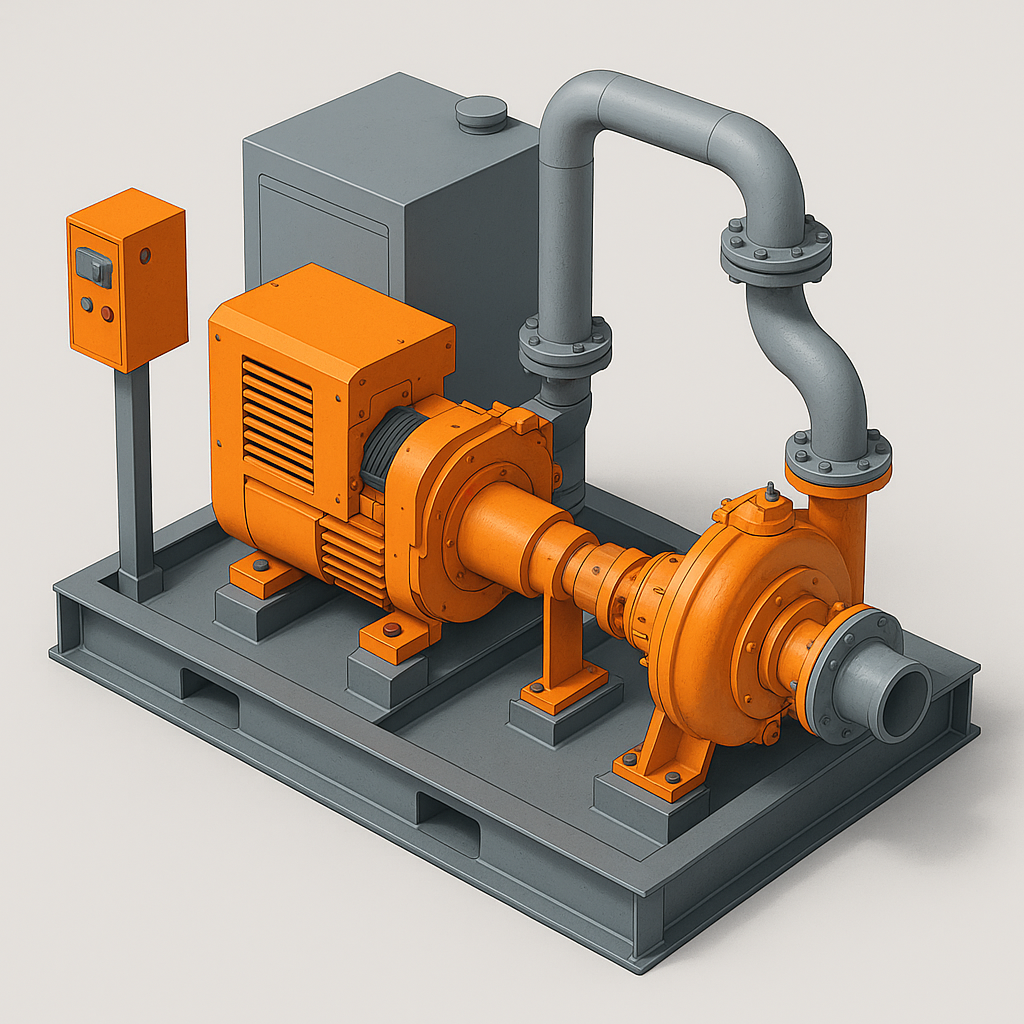

In industries where dirt, water, and heavy sludge collide—like mining, drilling, tunnelling, and civil construction—standard dewatering equipment just won’t cut it. That’s where a purpose-built mud dewatering pump comes in. Designed to handle thick, abrasive mixtures of water and solids, these pumps keep your site productive, compliant, and safe.

At MultiTorque, we supply and support rugged, high-performance mud dewatering pumps that are engineered specifically for harsh Australian worksites. With over 15 years of experience, we’ve helped clients across the mining, construction, agricultural, and infrastructure sectors keep mud and water under control.

What Is a Mud Dewatering Pump?

A mud dewatering pump is a heavy-duty pump specifically designed to move water mixed with high volumes of solids—such as clay, silt, bentonite, or drilling mud. These fluids are too thick and abrasive for standard dewatering pumps, which can clog, wear out, or overheat under such conditions.

MultiTorque’s mud pump systems are built to deliver:

- High solids-handling capability

- Abrasion-resistant internals

- Consistent flow even in thick, viscous fluid

- Long service life under high-duty cycles

- Trailer-mounted or skid-based mobility options

Whether you’re working in a coal pit or a trench in the suburbs, we build pump systems that move mud—and don’t quit.

Applications for Mud Dewatering Pumps

Mud dewatering pumps are critical in a variety of industries and environments, including:

- Mining – removing slurry from tailings dams and mine pits

- Drilling and exploration – handling bentonite and drilling mud

- Civil construction – trench, shaft, and foundation dewatering

- Tunnelling – muck removal from underground infrastructure work

- Agriculture – draining lagoons, sumps, and washdown areas

- Flood recovery – pumping debris-laden stormwater and sludge

If your fluid contains suspended solids or sediment, you need a pump built to take the punishment.

Pump Types Used for Mud Dewatering

MultiTorque supplies a range of pump types that excel in mud and slurry applications:

1. Diesel Trash Pumps

Surface-mounted, self-priming units powered by reliable diesel engines. These are ideal for mobile applications and remote worksites.

- Handles solids up to 76 mm

- Available with trailer or skid mount

- Easy to deploy with long hose reach

2. Electric Submersible Sludge Pumps

Designed to be dropped directly into sumps or pits, these submersible units are compact and powerful.

- Perfect for confined spaces or noise-restricted zones

- Solids handling up to 35 mm

- Continuous-duty rated for long-run jobs

3. Diaphragm Pumps

Air-powered, ideal for environments where electrical power is limited or hazardous.

- Self-priming and run-dry safe

- Low shear and suitable for thick, sticky mud

- Commonly used in waste transfer or chemical-laden sludge

4. Progressive Cavity Pumps

Excellent for controlled, low-pulsation flow of viscous muds or sludges.

- Smooth operation, great for thick or sticky material

- Used in processing and wastewater industries

- Easily integrated into skid or fixed systems

What Makes MultiTorque’s Mud Pump Solutions Stand Out?

✔ Built for Australia’s Harshest Environments

Every pump is selected and configured based on your site’s water type, flow demand, solids content, and layout.

✔ Custom-Built Systems

We fabricate pump trailers, bunded skids, hose reels, and enclosures in-house to meet your exact specs.

✔ Automation-Ready

Add float switches, level sensors, or control panels to operate your system automatically, day or night.

✔ Diesel, Electric, or Air Options

Whatever your power availability or compliance requirements, we supply the right driver for the job.

✔ High-Capacity Solutions

From compact 2” pumps to high-flow 8” systems, we handle everything from puddles to pit floods.

Real-World Success Stories

- QLD Mine Site: We deployed a trailer-mounted diesel trash pump system to dewater a pit flooded with heavy red clay slurry. The pump moved 2,000 L/min continuously over 6 days with zero clogging.

- Sydney Infrastructure Project: Electric submersible slurry pumps kept tunnel muck basins clean during metro expansion works. Low noise and automated controls meant 24/7 operation without manual oversight.

- Regional Agricultural Property: A diaphragm pump system was used to empty manure pits post-rainfall. Air-driven, easy to relocate, and corrosion-resistant.

Need to see technical specs or site reports? We’ve got them.

Service, Support, and Spare Parts

MultiTorque backs every pump with full after-sales support, including:

- Pump diagnostics and servicing

- Seal, impeller, and hose replacements

- Engine and electrical repairs

- Preventative maintenance programs

- Emergency breakdown callouts

- Spare part kits shipped Australia-wide

Our teams in Brisbane and Perth cover clients across Queensland, WA, and beyond.

Why Choose MultiTorque?

- ✅ 15+ years of industrial pump expertise

- ✅ Nationwide supply and support network

- ✅ Custom design and fabrication

- ✅ Responsive and honest service

- ✅ Trusted by contractors, miners, and operators

Whether you need one pump or a full dewatering system, we deliver solutions that work.

Let’s Talk Mud Management

If you’re battling thick sludge, messy runoff, or slow-moving silt, don’t settle for underpowered equipment. A purpose-built mud dewatering pump from MultiTorque will keep your site dry and your operations flowing.

📞 Call us now on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 LinkedIn: MultiTorque LinkedIn