Mono Type Pump: Reliable Solutions for Industrial Fluid Transfer 2025

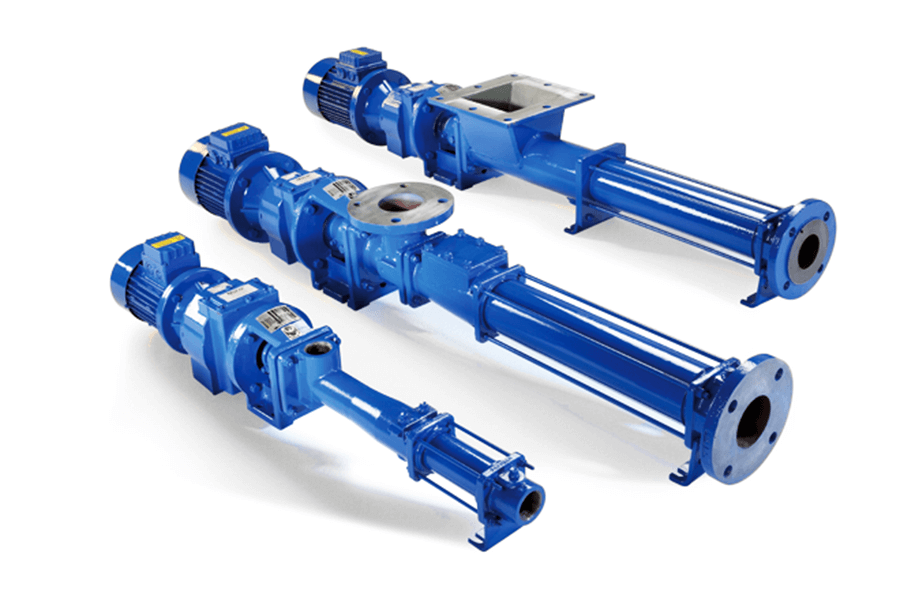

Industrial operations often demand pumps that are durable, versatile, and efficient. The Mono Type Pump is a progressive cavity pump designed to handle a wide range of fluids—including viscous, abrasive, and shear-sensitive materials—while maintaining consistent, low-pulsation flow. MultiTorque has over 15 years of experience supplying, servicing, and repairing Mono pumps across Australia, making us the trusted partner for industrial pumping solutions.

📞 Call 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit www.multitorque.com.au

🔗 Connect on LinkedIn

In this article, we’ll explore the features, benefits, applications, and maintenance of Mono Type Pumps and explain why MultiTorque is the preferred supplier for industrial fluid handling needs.

What is a Mono Type Pump?

A Mono Type Pump is a progressive cavity pump that moves fluid through a series of cavities formed by a helical rotor and elastomer stator. Unlike centrifugal pumps, which rely on high-speed impellers, the Mono Type Pump ensures smooth, consistent flow, even with challenging fluids such as:

- Highly viscous liquids

- Abrasive slurries

- Solids-laden fluids

- Shear-sensitive materials

The pump’s design allows it to perform reliably in industries where precision, durability, and safety are critical.

Key Features of Mono Type Pumps

Mono Type Pumps combine robust construction, efficient performance, and versatility. Key features include:

- Progressive Cavity Technology – Delivers smooth, low-pulsation flow.

- Durable Rotor and Stator – Handles abrasive, viscous, or chemically aggressive fluids.

- Energy Efficient Operation – Optimized for low-speed, high-efficiency performance.

- Low Maintenance – Modular design allows easy servicing and minimal downtime.

- Versatile Applications – Suitable for mining, wastewater, chemical processing, food, and agriculture.

Benefits of Using a Mono Type Pump

1. Reliable Performance

The progressive cavity design ensures consistent fluid movement, reducing the risk of operational interruptions and equipment wear.

2. Handles Diverse Fluids

From thick slurries to shear-sensitive liquids, Mono Type Pumps manage various fluids without damaging the system.

3. Cost-Effective Operation

Low maintenance requirements and high energy efficiency translate into reduced operational costs over the pump’s lifespan.

4. Enhanced Safety

The pump’s controlled flow reduces pressure surges, spills, and equipment damage, enhancing safety in industrial operations.

Applications of Mono Type Pumps

The Mono Type Pump is highly versatile and can be used across many industries:

- Mining – Transfer of slurries, tailings, and dewatering.

- Wastewater Treatment – Pumping sludge, polymers, and chemicals with minimal blockages.

- Food & Beverage – Safe handling of shear-sensitive liquids like sauces, syrups, and dairy products.

- Chemical Processing – Handling viscous or abrasive chemicals safely and efficiently.

- Agriculture – Irrigation, effluent management, and slurry handling.

Its ability to manage abrasive and viscous fluids makes the Mono Type Pump an essential solution for industrial operations.

Related Pump Solutions

MultiTorque offers a wide range of pump solutions that complement Mono Type Pumps:

- Mono MS Pump – Ideal for heavy-duty progressive cavity pumping.

- Mono X Pump – High-performance pumps for demanding applications.

- Allweiler Screw Pump – Efficiently handles viscous and abrasive fluids.

- Electric Diaphragm Water Pump – Portable, energy-efficient pumping solution.

- Ingersoll Rand ARO Pump Rebuild Kit – Extend pump life with high-quality rebuild kits.

These related solutions ensure that clients can select the right pump or component for any industrial fluid handling requirement.

Maintaining Your Mono Type Pump

Proper maintenance ensures the longevity and efficiency of your Mono Type Pump:

- Routine Inspection – Check rotor, stator, and seals for signs of wear or damage.

- Lubrication and Alignment – Ensure components are correctly lubricated and aligned.

- Stator Replacement – Replace the stator when excessive wear is detected to maintain optimal performance.

- Use Genuine Parts – Always use OEM or high-quality replacement parts to reduce downtime and prevent failures.

Regular maintenance ensures maximum efficiency, reduces operational interruptions, and extends the life of your pump.

MultiTorque: Your Mono Pump Partner

With over 15 years of experience, MultiTorque is a trusted provider of Mono pumps, including Mono Type Pumps. Our services include:

- Supply of Mono Type Pumps – High-quality pumps tailored to operational requirements.

- Workshop Repairs and Rebuilds – In-house servicing ensures reliable repair work.

- Spare Parts Availability – Genuine components for Mono and other pump brands.

- Custom Pump Systems – Design and build of specialized pumping systems, mobile units, and trailers.

By partnering with MultiTorque, you ensure your Mono Type Pump operates at peak efficiency with minimal downtime.

Why Choose MultiTorque?

- Australian Expertise – With branches in Perth and Brisbane, we support clients nationwide.

- Extensive Industry Experience – Over 15 years servicing mining, water treatment, agriculture, and chemical industries.

- Comprehensive Support – Supply, repair, and maintenance handled in-house.

- Focus on Reliability and Safety – Every pump and service meets strict industry standards.

- Long-Term Client Partnerships – Committed to building trusted, lasting relationships.

Contact MultiTorque

For reliable Mono Type Pumps or pump servicing, contact MultiTorque:

📞 Call 1300 726 525

📧 Email sales@multitorque.com

🌐 Visit www.multitorque.com.au

🔗 Connect on LinkedIn

Conclusion

The Mono Type Pump is a versatile, durable, and efficient solution for industrial fluid handling. Its progressive cavity design ensures consistent, low-pulsation flow while safely handling viscous, abrasive, or shear-sensitive fluids.

With MultiTorque’s supply, in-house servicing, and expertise, your Mono Type Pump will deliver reliable performance, reduced downtime, and long-term efficiency. Whether in mining, wastewater, chemical processing, food & beverage, or agriculture, MultiTorque provides the knowledge, parts, and support needed to keep your pumps operating at their best.