Mono Screw Pump: Powerful Solution for Viscous and Abrasive Fluids 2025

When it comes to handling thick, abrasive, or delicate fluids with pinpoint precision, nothing beats the reliability of a mono screw pump. These versatile, positive displacement pumps are ideal for a wide range of industrial applications—from wastewater treatment and mining to food processing and agriculture.

At MultiTorque, we supply and service high-quality mono screw pumps across Australia. Whether you need a pump for sludge, slurry, or nutrient dosing, we’ve got the expertise and equipment to deliver.

What Is a Mono Screw Pump?

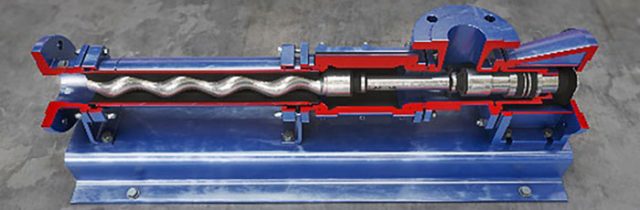

A mono screw pump, also known as a progressive cavity pump, uses a rotating metal screw (rotor) inside a rubber stator to move fluid through the pump in a continuous, smooth flow.

As the rotor turns inside the stator, cavities form and progress along the pump body—moving fluid without pulsation or turbulence. This makes the mono screw pump ideal for materials that are:

-

Viscous or sticky

-

Contain solids or grit

-

Chemically aggressive

-

Shear-sensitive

Key Benefits of Mono Screw Pumps

Here’s why industries across Australia are turning to mono screw pumps:

✅ Smooth, Pulsation-Free Flow

The progressive cavity design ensures consistent and controlled flow, which is crucial for dosing and metering applications.

✅ Handles Thick and Gritty Fluids

From wastewater sludge to drilling mud, these pumps take on high solids content without flinching.

✅ Low Shear Movement

Gentle fluid handling protects sensitive materials like food-grade ingredients or chemical solutions.

✅ Self-Priming & Suction Lift

Mono screw pumps can draw fluid from tanks and sumps below ground level, making them ideal for tough installations.

✅ Reversible Operation

Need to flush a line or reverse flow? Mono screw pumps can operate in both directions.

Common Applications of Mono Screw Pumps

💧 Wastewater Treatment

-

Sludge transfer

-

Polymer dosing

-

Lime slurry

-

Dewatering feeds

⛏️ Mining & Resources

-

Tailings transport

-

Drilling fluid movement

-

Chemical dosing for pH balancing

🍅 Food & Beverage

-

Tomato paste, fruit pulp, or honey transfer

-

Dough or mash handling

-

Syrup and sauces

🌾 Agriculture

-

Fertiliser injection

-

Manure and effluent transfer

-

Molasses dosing

🏭 Industrial & Chemical

-

Resin, paint, and adhesive movement

-

Chemical transfer

-

Sludge with grit or sand content

Mono Pump Parts and Servicing

At MultiTorque, we don’t just sell pumps—we keep your system running with:

-

🛠️ Rotor and stator replacements

-

🔧 Seal kits and wear parts

-

🔁 Pump rebuilds and overhauls

-

🧰 Custom trailer-mounted mono pump units

-

⚡ Control panels built in-house by licensed sparkies

We supply parts and full units compatible with Mono®, Orbit, NOV, and other industry-leading brands, and can customise builds for both portable and fixed installations.

Why Choose MultiTorque?

With over 15 years in the game, MultiTorque is trusted by Australian industry leaders to provide pump systems that work under pressure. Our clients rely on us for:

-

🧠 Expert pump advice

-

⚙️ Customised solutions for unique fluid challenges

-

🔩 Heavy-duty builds for remote and harsh environments

-

🛻 Mobile trailer units and integrated control systems

-

📦 Fast supply of spare parts across the country

From Perth to Brisbane and everywhere in between, we keep Australia’s industries pumping.

Get a Mono Screw Pump That Gets the Job Done

Need a mono screw pump for your site? Whether you’re handling sludge, slurry, paste, or polymer, MultiTorque delivers performance you can count on.

📞 Call MultiTorque on 1300 726 525

🌐 Visit www.multitorque.com.au

🔗 Follow us on LinkedIn

📧 Email: sales@multitorque.com