Mono Pump Stator: Top Supplier Australia MultiTorque 2025

In the world of industrial pumping solutions, efficiency and reliability are key to keeping operations running smoothly. One critical component that plays a huge role in the performance of progressive cavity pumps is the mono pump stator. Whether you’re running a mine site, processing plant, or water treatment facility, understanding how a stator functions—and when it needs replacing—can save you downtime, money, and a lot of headaches.

📞 Call us on 1300 726 525

📧 Email us at sales@multitorque.com

At MultiTorque, we’ve been supplying, servicing, and repairing pumps across Australia for more than 15 years. With our experience in progressive cavity pumps and their components, we know just how important the stator is in ensuring long-term performance. Let’s dive into what a mono pump stator does, how to maintain it, and where to source quality replacements.

What Is a Mono Pump Stator?

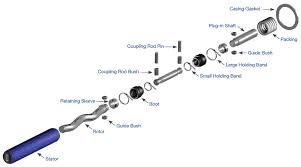

A mono pump stator is the elastomer sleeve that sits inside the pump housing of a progressive cavity pump. It works in tandem with the rotor, creating sealed cavities that move fluid through the pump with minimal pulsation. The stator is typically made from durable rubber compounds, designed to withstand abrasion, chemicals, and varying temperatures.

Without the stator, the pump cannot operate effectively, as it provides the sealing mechanism required for progressive cavity pumping. Choosing the right stator material for your application—whether that’s nitrile rubber, EPDM, or Viton—is essential for both efficiency and durability.

Why the Stator Matters in Progressive Cavity Pumps

The mono pump stator is the wear component most exposed to stress within the pump. As slurry, wastewater, chemicals, or oil-based fluids pass through the pump, the stator provides the necessary sealing force. Over time, this constant contact and friction lead to gradual wear.

When the stator begins to degrade, performance issues follow:

- Reduced pumping efficiency

- Loss of pressure

- Increased power consumption

- Risk of pump seizure if ignored

Regular monitoring and replacement of the stator is crucial for keeping your operations online without costly downtime.

Signs Your Mono Pump Stator Needs Replacing

Every operator should know how to spot the early warning signs of stator wear. Here are the most common indicators that your mono pump stator might be on its way out:

- Drop in performance – Pump isn’t moving as much fluid as before.

- Increased vibration – Misalignment or wear in the stator cavity can cause unusual pump vibration.

- Higher energy use – The pump motor is working harder than usual, drawing more power.

- Leaks or bypassing – Fluid may pass through gaps caused by worn stator surfaces.

- Visible wear – On inspection, you can see cracks, swelling, or distortion in the stator rubber.

Addressing these issues early saves money, prevents catastrophic pump failure, and avoids emergency downtime.

Choosing the Right Mono Pump Stator

Not all stators are created equal. The type of elastomer and the quality of the manufacturing process directly impact lifespan.

Some key factors to consider when selecting a stator include:

- Fluid type – Chemicals, slurries, and wastewater each demand specific elastomers.

- Temperature range – Higher heat requires materials like Viton, while cooler environments can use nitrile.

- Chemical compatibility – Using the wrong elastomer can cause swelling, cracking, or rapid breakdown.

- Pump model – Each stator must be matched precisely to your rotor and pump housing.

At MultiTorque, we stock and supply mono pump stators for a wide range of pump models, ensuring you get the right fit for your specific application.

Maintenance Tips to Extend Stator Life

While the stator will eventually need replacing, proper maintenance can extend its service life:

- Use the correct elastomer for your fluid and environment.

- Avoid dry running – Running a progressive cavity pump without fluid causes extreme friction and rapid stator wear.

- Monitor operating conditions – Excessive pressure or speed shortens stator lifespan.

- Schedule regular inspections – Catching early signs of wear prevents complete failure.

- Keep spare stators on hand – Critical sites should always have a replacement ready to minimise downtime.

By following these practices, operators can significantly reduce unexpected breakdowns.

MultiTorque: Your Source for Mono Pump Stators

When it comes to sourcing reliable, high-quality mono pump stators in Australia, MultiTorque has you covered. We supply, service, and repair pumps from trusted brands like NOV, Orbit, Napco, and Wilden.

Why choose us?

- Experienced team – 15+ years in the pump industry

- Specialist knowledge – Experts in progressive cavity pumps and their components

- Custom solutions – If your site needs something unique, we’ll design and supply to match

- Trusted partners – Long-term relationships with clients across mining, oil & gas, agriculture, and water treatment

We don’t just sell pump parts—we ensure you get the right stator for your application, backed by service you can trust.

To explore our full range of pump parts and services, visit our MultiTorque homepage.

You can also connect with us directly on our official MultiTorque LinkedIn page for updates, projects, and industry insights.

Get in Touch Today

If your operations are being held back by a worn-out mono pump stator, don’t wait for downtime to hit. At MultiTorque, we can supply quality stators quickly, ensuring your pump is back to peak performance in no time.

📞 Call us on 1300 726 525

📧 Email us at sales@multitorque.com

Keep your pumps reliable. Keep your site productive. Choose MultiTorque.