Mono Progressive Cavity Pump: The Powerful Operator of Fluid Transfer 2025

When the job calls for precision, consistency, and the ability to handle tough fluids, the mono progressive cavity pump is a go-to solution. Known for their smooth, low-pulse flow, these pumps are essential across a range of Australian industries—from wastewater to food processing to oil and gas.

At MultiTorque, we supply, repair, and support mono progressive cavity pumps and components for operations that can’t afford downtime. Whether you need a full pump system, parts like rotors and stators, or a custom trailer build—we’ve got the torque to get it done.

What Is a Mono Progressive Cavity Pump?

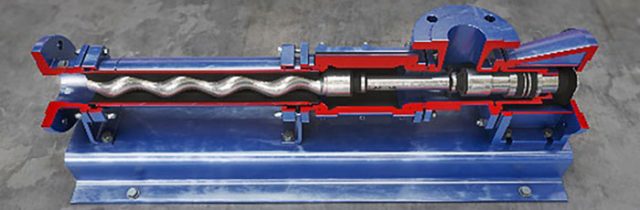

A mono progressive cavity pump is a type of positive displacement pump that moves fluid through a series of small, fixed-shape cavities. It uses a single helical rotor that turns inside a double helical stator, creating sealed chambers that move fluid forward as the rotor rotates.

This action produces:

-

✅ Smooth, continuous flow

-

✅ Low shear—great for delicate fluids

-

✅ Precise dosing and flow control

-

✅ Ability to handle thick, abrasive, or corrosive fluids

It’s called a “mono” pump because it originated from Mono Pumps, a major brand name, but the term is now commonly used to refer to this pump style in general.

Key Benefits of Mono Progressive Cavity Pumps

Why are these pumps trusted across harsh industries?

🔄 Constant, Pulsation-Free Flow

Ideal for metering and accurate dosing, especially in chemical or food processing.

💪 Handles Viscous & Abrasive Media

Sludge, slurry, pastes, and wastewater? No problem.

🧩 Modular Design

Easily replace rotors, stators, seals, and bearings.

🧼 Hygienic Models Available

Perfect for food-grade, dairy, and cosmetic applications.

📏 Excellent Suction Lift

Can draw fluid from depths or tanks with low inlet pressure.

Where Mono Progressive Cavity Pumps Are Used

We regularly supply these pumps across industries like:

💧 Wastewater Treatment

-

Sludge thickening

-

Polymer dosing

-

Dewatering feed systems

⛏️ Mining & Minerals

-

Thickened tailings

-

Paste and slurry transfer

-

Dewatering sumps

🛢️ Oil & Gas

-

Crude oil and condensate pumping

-

Chemical injection

-

Mud and drilling fluid transfer

🍅 Food & Beverage

-

Fruit puree, mash, syrup, and sauce transfer

-

Gentle product handling

-

Clean-in-place (CIP) capability

🌾 Agriculture

-

Effluent handling

-

Fertiliser injection

-

Animal waste transfer

Need Replacement Parts?

We stock and supply rotors, stators, seals, and gearboxes for mono progressive cavity pumps—including aftermarket and OEM equivalents.

MultiTorque also provides:

-

🛠️ On-site pump servicing

-

🔁 Rotor & stator replacement

-

🔧 Pump strip-downs and rebuilds

-

🚚 Mobile trailer pump units built to spec

If you need a part fast, we’ve got stock in both our Perth and Brisbane branches—ready for immediate dispatch across Australia.

Why Choose MultiTorque?

With over 15 years of industry experience, MultiTorque delivers more than just products—we deliver performance, service, and results.

Here’s why clients choose us for mono progressive cavity pumps:

-

✅ Full system builds and trailer-mounted setups

-

✅ Custom control panels and automation by in-house sparkies

-

✅ Field servicing and rapid part turnaround

-

✅ Trusted supplier of NOV, Mono®, Orbit, and other major brands

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

✅ Friendly, knowledgeable support that puts your uptime first

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

Get the Right Pump, First Time

Whether you’re moving sludge in a remote mine site or dosing chemicals at a wastewater facility, MultiTorque has the right mono progressive cavity pump for your job.

📞 Call MultiTorque on 1300 726 525

🌐 Visit www.multitorque.com.au

🔗 Follow us on LinkedIn

📧 Email: sales@multitorque.com

Let’s move what others can’t.