Mono MS Pump: Reliable Progressive Cavity Pump Solutions with MultiTorque 2025

Industrial fluid handling requires pumps that are precise, efficient, and durable. The Mono MS pump is engineered to meet these exacting standards, providing reliable performance for a wide range of applications. Whether you are working in chemical processing, food and beverage, wastewater management, or industrial manufacturing, the Mono MS pump ensures consistent flow, low pulsation, and long-term reliability.

MultiTorque supplies, services, and maintains Mono MS pumps across Australia. With over 15 years of experience, we provide genuine parts, rebuild kits, and expert in-house servicing to ensure your pumps continue to perform at their best.

- 📞 Call 1300 726 525

- 📧 Email sales@multitorque.com

- 🌐 Visit www.multitorque.com.au

- 🔗 Connect on LinkedIn

What Is a Mono MS Pump?

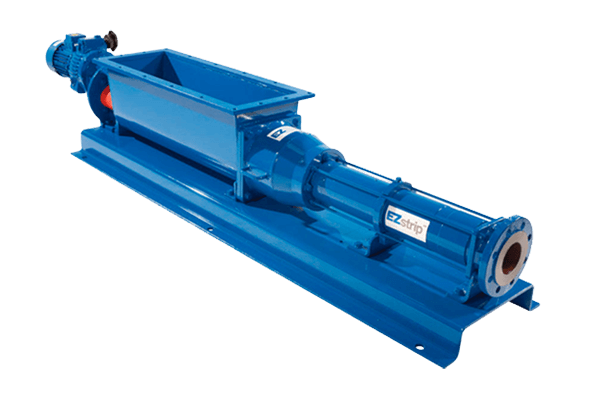

The Mono MS pump is a progressive cavity pump designed to handle a variety of liquids, including viscous, shear-sensitive, and multiphase fluids. As a positive displacement pump, it delivers smooth, continuous flow, which is essential for industrial processes requiring precision and consistency.

Key features of Mono MS pumps include:

- Reliable Performance: Maintains consistent flow even with highly viscous or abrasive liquids.

- Durable Construction: Built to withstand challenging industrial conditions.

- Low Maintenance Requirements: Designed for long service intervals with easily replaceable components.

- Versatility: Suitable for chemical, food-grade, and industrial applications.

Mono MS pumps are ideal for applications where accuracy, durability, and reliability are paramount.

Applications of Mono MS Pumps

Mono MS pumps are widely used in industries requiring precise fluid handling:

- Chemical Processing: Transfer of acids, solvents, and other corrosive liquids safely.

- Food & Beverage: Pumping viscous food-grade products such as syrups, oils, and sauces.

- Wastewater Management: Efficiently handling sludge, wastewater, and other viscous fluids.

- Industrial Manufacturing: Circulation of lubricants, oils, and process fluids.

- Oil & Gas: Safe and efficient pumping of crude oil, refined products, and other hydrocarbons.

By choosing Mono MS pumps, businesses can achieve smooth and reliable fluid transfer, improving productivity and process efficiency.

Key Components of Mono MS Pumps

Proper maintenance of Mono MS pumps ensures optimal performance and long lifespan. Key components include:

- Rotor & Stator: Core elements that provide progressive cavity pumping action.

- Seals & Gaskets: Prevent leaks and maintain pressure integrity.

- Drive Shaft & Couplings: Transfer mechanical energy efficiently to the rotor.

- Bearings: Support rotor movement and reduce friction.

- Pump Casing: Protects internal components and directs fluid flow.

MultiTorque provides genuine Mono MS pump parts and rebuild kits, ensuring compatibility, durability, and reliability.

Benefits of Maintaining Mono MS Pumps

Investing in proper maintenance and using genuine parts for Mono MS pumps offers numerous advantages:

1. Extended Pump Lifespan

Replacing worn components prevents premature failures and reduces the need for full pump replacements.

2. Consistent Flow and Pressure

Maintaining critical components ensures smooth, reliable flow, crucial for sensitive industrial processes.

3. Cost-Effective Operation

Preventative maintenance reduces unexpected downtime and repair costs.

4. Reduced Operational Downtime

Proactive servicing ensures fewer interruptions, enhancing productivity and efficiency.

5. Safety and Compliance

Maintaining seals and gaskets prevents leaks, ensuring safe handling of chemicals and other fluids while complying with industrial safety standards.

Signs Your Mono MS Pump Needs Servicing

Recognizing early warning signs of wear helps prevent unexpected failures:

- Reduced flow rate or pressure

- Unusual noises such as rattling, grinding, or squealing

- Leaks around seals or pump casing

- Excessive vibration

- Increased motor or bearing temperature

Using genuine Mono MS pump parts and rebuild kits from MultiTorque ensures your pump maintains peak performance.

Maintenance Tips for Mono MS Pumps

To maximise the efficiency and lifespan of your Mono MS pump, follow these best practices:

- Regular Inspection: Check rotors, stators, seals, and bearings for wear or damage.

- Lubrication: Ensure bearings and couplings are properly lubricated to prevent overheating.

- Clean Fluid Pathways: Avoid debris buildup in inlets and outlets.

- Scheduled Rebuilds: Replace key components according to manufacturer recommendations.

- Monitor Performance: Track flow, pressure, vibration, and temperature to detect issues early.

MultiTorque provides in-house servicing, rebuilds, and expert advice to ensure your Mono MS pump operates reliably.

Why Choose MultiTorque for Mono MS Pumps?

MultiTorque is a trusted supplier and service provider for industrial pumps across Australia. Choosing MultiTorque gives you:

- Genuine Mono MS Pump Parts & Rebuild Kits: Ensuring compatibility, durability, and reliable performance.

- Experienced Technicians: Skilled in in-house servicing, inspection, and pump rebuilds.

- Custom Solutions: Tailored guidance to meet your operational requirements.

- Nationwide Support: Serving clients in Perth, Brisbane, and across Australia.

- Long-Term Reliability: Focused on maintaining equipment performance and safety.

Learn more about our services at MultiTorque’s homepage and connect on LinkedIn.

How MultiTorque Supports Pump Reliability

By providing genuine Mono MS pump parts and rebuild kits, MultiTorque helps businesses:

- Maintain consistent flow and pressure for industrial processes

- Reduce downtime through proactive maintenance and rebuilds

- Save costs by extending the operational life of pumps

- Ensure safety and compliance in chemical, food, and industrial fluid handling

Our team offers guidance on rebuild schedules, part selection, and preventative maintenance programs to keep your pumps running efficiently.

Ordering Mono MS Pump Parts

Obtaining rebuild kits or replacement parts for Mono MS pumps is simple with MultiTorque:

- Identify your pump model and operational requirements

- Contact MultiTorque to confirm part compatibility and availability

- Receive expert guidance on installation and maintenance

- Replace worn components with genuine parts to restore optimal performance

MultiTorque ensures that maintaining your Mono MS pump is straightforward, reliable, and cost-effective.

Contact MultiTorque Today

Keep your Mono MS pump performing at its best with MultiTorque:

- 📞 Call 1300 726 525

- 📧 Email sales@multitorque.com

- 🌐 Visit www.multitorque.com.au

- 🔗 Connect on LinkedIn

Partner with MultiTorque for genuine Mono MS pump parts, rebuild kits, and expert in-house servicing across Australia.