Mono Epsilon Pumps: Powerful Solutions From MultiTorque 2025

When it comes to handling abrasive, viscous, or shear-sensitive fluids, not every pump is built to perform. That’s where the Mono Epsilon pump comes in—a heavy-duty progressive cavity pump designed for industries that demand reliability, durability, and efficiency. In Australia, businesses across mining, wastewater, food processing, and oil & gas rely on Mono Epsilon pumps to keep operations running smoothly.

At MultiTorque, we specialise in supplying, repairing, and servicing progressive cavity pumps—including the Mono Epsilon range—for clients across Australia. With over 15 years of industry expertise, we ensure our customers have access to the right pump solutions, backed by in-house workshop repair services and long-term support.

📞 Call us today at 1300 726 525

📧 Email us at sales@multitorque.com

🌐 Visit us at www.multitorque.com.au

For more updates and industry insights, connect with us on LinkedIn.

What is the Mono Epsilon Pump?

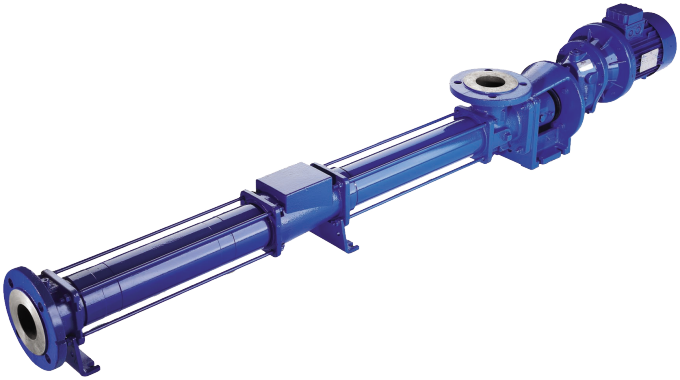

The Mono Epsilon pump is a progressive cavity pump designed to handle challenging applications where standard centrifugal pumps often fail. Using a helical rotor and stator mechanism, it provides continuous, low-pulsation flow while maintaining gentle handling of sensitive media.

Key features of the Mono Epsilon series include:

- Heavy-duty design for abrasive and corrosive fluids.

- Low shear pumping – ideal for shear-sensitive products such as food ingredients, polymers, and chemicals.

- Steady flow with minimal pulsation, reducing wear on downstream equipment.

- High efficiency across a wide viscosity range, from thin liquids to highly viscous slurries.

- Extended service intervals due to robust engineering and simple maintenance.

These characteristics make Mono Epsilon pumps a trusted choice for industries where uptime and reliability are critical.

Applications of Mono Epsilon Pumps

One of the main reasons the Mono Epsilon pump is widely used in Australia is its versatility. It can handle fluids that would cause rapid wear or performance issues in other pump types.

Common applications include:

- Mining: Transfer of abrasive slurries, tailings, and chemical additives.

- Wastewater treatment: Handling sludge, biosolids, and thickened waste streams.

- Food & beverage: Gentle transfer of sauces, dairy products, fruit pulp, and yeast.

- Oil & gas: Handling drilling mud, oily sludges, and produced water.

- Chemical processing: Accurate dosing and transfer of aggressive or viscous chemicals.

By providing controlled, consistent flow, the Mono Epsilon pump reduces downtime and supports efficiency in even the harshest working environments.

Benefits of Choosing Mono Epsilon Pumps

Businesses across Australia choose the Mono Epsilon range for several reasons:

- Durability – Built to handle high-wear applications, extending service life compared to standard pumps.

- Cost-effectiveness – Lower energy consumption and reduced maintenance requirements save costs over time.

- Flexibility – Able to process both low-viscosity and high-viscosity fluids without compromising flow.

- Reduced downtime – Long intervals between servicing minimise operational interruptions.

- Proven reliability – With decades of use in demanding industries, Mono pumps are a trusted brand worldwide.

For Australian industries that rely on equipment running around the clock, these benefits are invaluable.

MultiTorque: Your Mono Epsilon Partner in Australia

At MultiTorque, we supply, service, and repair Mono Epsilon pumps for clients across Perth, Brisbane, and beyond. Our in-house workshops are equipped to handle heavy-duty pump rebuilds, ensuring that your equipment is restored to peak performance.

Unlike some suppliers, we don’t just sell pumps—we provide complete lifecycle support. From helping you select the right model to providing OEM and aftermarket parts, MultiTorque is committed to reliability and long-term client partnerships.

We specialise in:

- Sales and sourcing of Mono Epsilon pumps and spare parts.

- In-house pump repairs – no on-site repairs, but expert workshop rebuilds.

- Preventive maintenance programs to extend equipment lifespan.

- Custom solutions for challenging applications.

Our reputation for safety, reliability, and customer service has made us a trusted partner for industries across Australia.

Why Progressive Cavity Pumps Outperform in Harsh Applications

The design of the Mono Epsilon pump gives it an edge over centrifugal and diaphragm pumps in many industries.

- Progressive cavity technology provides constant flow regardless of pressure variations.

- Handles abrasive and viscous materials better than many pump types.

- Low shear ensures product quality in sensitive industries like food and chemicals.

- Self-priming capabilities allow it to handle challenging suction conditions.

For businesses seeking to minimise equipment breakdowns and maximise productivity, the Mono Epsilon is a proven solution.

Spare Parts and Maintenance for Mono Epsilon

One of the biggest challenges in heavy industries is equipment downtime due to unavailable parts. At MultiTorque, we understand this—which is why we stock and source Mono Epsilon spares to keep your pumps operational.

Common parts we supply and replace include:

- Rotors and stators

- Seals and bearings

- Drive assemblies

- Couplings and wear components

By working with MultiTorque, you gain a partner that ensures your Mono Epsilon pump stays in top condition, minimising costly downtime.

MultiTorque’s Industry Experience

With over 15 years in business, MultiTorque has built long-term relationships with clients across mining, wastewater, oil & gas, and manufacturing. Our team is dedicated to providing solutions that align with your operational needs.

Whether you need a new Mono Epsilon pump, parts supply, or expert repairs, MultiTorque is your go-to partner in Australia.

We don’t just provide equipment—we provide confidence and reliability.

Connect with MultiTorque

If you’re looking for Mono Epsilon pumps in Australia, MultiTorque is ready to assist. Our workshops in Perth and Brisbane serve clients nationwide, ensuring access to high-quality pumps, parts, and repair services.

📞 Call us today at 1300 726 525

📧 Email us at sales@multitorque.com

🌐 Visit us at www.multitorque.com.au

For more updates and industry insights, connect with us on LinkedIn.