Mining Slurry Pumps: Powerful Supply for Mine Operations 2025

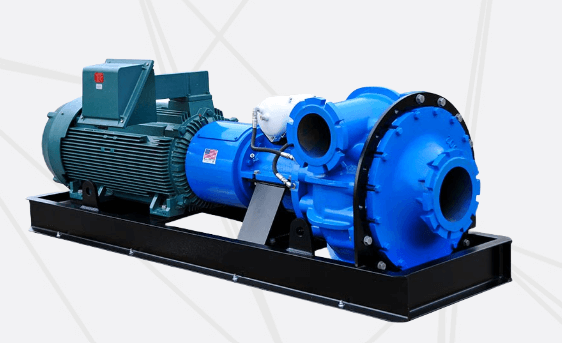

Mining is one of the most demanding industries in the world, and the equipment used in this sector must withstand some of the harshest operating conditions imaginable. Among the critical machinery that keeps mining operations running smoothly are mining slurry pumps. These specialized pumps are designed to handle abrasive slurries, thick fluids, and mixtures of water and solids, making them indispensable for transporting tailings, minerals, and waste material.

📞 Contact MultiTorque today at 1300 726 525 or email sales@multitorque.com to discuss your mining slurry pump needs.

Visit us online at www.multitorque.com.au and follow us on LinkedIn for updates.

In this article, we’ll break down what mining slurry pumps are, why they are so vital to mine sites, and how MultiTorque can support your operation with supply, service, and repairs.

What Are Mining Slurry Pumps?

Mining slurry pumps are heavy-duty pumps built to move mixtures of liquid and solid particles from one location to another. Unlike standard pumps, they are designed to handle:

- Highly abrasive fluids containing rocks, sand, or other sharp particles

- Corrosive mixtures of chemicals and water

- High-density slurries that put immense strain on moving parts

These pumps are typically centrifugal or positive displacement in design, with reinforced materials such as high-chrome alloys and rubber linings to resist wear. Their primary purpose is to keep slurry moving continuously, ensuring production does not come to a standstill.

Key Applications of Slurry Pumps in Mining

Slurry pumps are used in nearly every stage of mining. Some common applications include:

- Ore Transportation – Moving processed ore in the form of slurry from crushers and mills to separation equipment.

- Tailings Disposal – Transporting waste material to designated storage or tailings dams.

- Mill Discharge – Handling the heavy slurry that exits ball mills or SAG mills.

- Mine Dewatering – Removing excess water mixed with solids from mine shafts.

- Chemical Processing – Pumping corrosive slurries involved in mineral extraction.

Without reliable slurry pumps, these processes would face constant downtime, driving up costs and reducing productivity.

Why Are Mining Slurry Pumps So Important?

The mining industry runs on efficiency. When pumps fail, the consequences are immediate and expensive. Downtime can halt production, cause delays in shipping, and increase operational costs. Mining slurry pumps solve this problem by:

- Ensuring continuous operation even with highly abrasive and corrosive materials

- Reducing maintenance frequency thanks to durable construction

- Improving safety by preventing blockages and spills

- Enhancing productivity through efficient transport of slurries across long distances

Simply put, a mine without reliable slurry pumps cannot operate at maximum capacity.

Features of a High-Quality Mining Slurry Pump

Not all slurry pumps are created equal. The best mining slurry pumps are designed with features that enhance durability and efficiency. Key characteristics include:

- Wear-resistant materials such as natural rubber, polyurethane, or hardened alloys

- Replaceable liners and impellers for easy maintenance

- High efficiency impeller designs to reduce energy consumption

- Heavy-duty bearings and shafts to handle high loads

- Modular design for quick part replacement and servicing

These features allow mining slurry pumps to withstand continuous operation under extreme conditions, ensuring reliability over the long term.

Types of Mining Slurry Pumps

Different applications call for different pump designs. The most common types used in mining include:

- Centrifugal Slurry Pumps – The most widely used, relying on centrifugal force to move slurry. Ideal for medium to high flow rates.

- Horizontal Slurry Pumps – Positioned horizontally, often used for heavy-duty tasks where high volumes are needed.

- Vertical Slurry Pumps – Ideal for sump applications where the pump is submerged directly in slurry.

- Submersible Slurry Pumps – Completely immersed in the fluid, useful in confined spaces and dewatering.

- Positive Displacement Slurry Pumps – Best suited for high-pressure, low-flow applications.

Choosing the right type depends on the specific mine site requirements, including the slurry composition, distance, and pressure needed.

Challenges Faced by Mining Slurry Pumps

Mining slurry pumps operate under constant stress, and as such, they face unique challenges:

- Excessive Wear and Tear – Abrasive solids erode impellers and casings quickly.

- Clogging – Oversized particles can jam pumps and disrupt operations.

- Corrosion – Chemical exposure in mineral processing can shorten pump life.

- High Power Consumption – Inefficient pumps drive up operational costs.

These challenges highlight why pump selection, installation, and ongoing servicing are so important.

MultiTorque’s Expertise in Slurry Pump Solutions

At MultiTorque, we understand the demands of the mining sector and the vital role slurry pumps play in day-to-day operations. That’s why we provide a comprehensive range of services to ensure your equipment operates at peak efficiency.

- Supply of Mining Slurry Pumps – We source and supply high-performance slurry pumps built to handle the harshest environments.

- Workshop Repairs – Our in-house technicians are experienced in diagnosing and repairing all major brands of slurry pumps.

- Spare Parts and Components – From impellers to liners, we stock and source critical spare parts to minimise downtime.

- Custom Solutions – We provide tailored modifications to pumps for specific site requirements.

With branches in Perth and Brisbane, we service clients across Australia, delivering reliability and long-term value.

Choosing the Right Partner for Mining Slurry Pumps

Selecting the right slurry pump is only part of the equation—choosing the right supplier is equally critical. MultiTorque offers the technical expertise, parts availability, and after-sales service needed to keep mining operations running smoothly. We pride ourselves on building long-term relationships with our clients, ensuring their pumps remain reliable year after year.

Conclusion

Mining slurry pumps are the unsung heroes of mine operations. From transporting abrasive tailings to handling corrosive slurries, they perform some of the toughest jobs on site. Their reliability directly impacts productivity, safety, and operating costs.

By partnering with a trusted provider like MultiTorque, mining companies gain access to not only durable pumps but also expert servicing and tailored solutions. If you need a dependable partner for your slurry pumping requirements, look no further than MultiTorque.

📞 Contact MultiTorque today at 1300 726 525 or email sales@multitorque.com to discuss your mining slurry pump needs.

Visit us online at www.multitorque.com.au and follow us on LinkedIn for updates.