Internal Gear Pump: Precision Pumping for Viscous Fluids and Oils 2025

When it comes to moving thick, viscous, or lubricating fluids with precision and quiet efficiency, few pumps compare to the internal gear pump. Compact, durable, and self-priming, this pump style is a workhorse across industries like oil & gas, food processing, chemical manufacturing, and lubrication systems.

At MultiTorque, we supply, repair, and support internal gear pumps across Australia, helping industrial operators keep their systems flowing with zero fuss.

What Is an Internal Gear Pump?

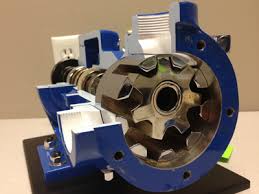

An internal gear pump is a type of positive displacement pump that uses two intermeshing gears—one inside the other—to move fluid. The outer gear (called the rotor) drives the inner gear (called the idler), creating a sealed cavity that transports fluid from the inlet to the outlet.

A crescent-shaped spacer between the gears maintains separation and optimises flow, allowing for smooth, continuous transfer with very little pulsation.

How It Works

-

Fluid enters the pump casing through the inlet.

-

As the gears rotate, they create expanding cavities that draw fluid in.

-

The fluid is carried between the gear teeth and the casing.

-

As the gears re-mesh on the outlet side, the cavity size decreases, pushing the fluid out under pressure.

The result? Smooth, reliable flow even with high-viscosity or shear-sensitive fluids.

Key Features and Benefits

-

Self-Priming: Can lift fluids from below pump level, ideal for tank-to-tank transfer.

-

Handles Viscous Fluids: Excellent for gear oil, molasses, adhesives, asphalt, and more.

-

Reversible Flow: Can operate in either direction without modification.

-

Compact and Quiet: Low noise and vibration compared to external gear or vane pumps.

-

Precise Flow Control: Great for dosing or metering applications with thick liquids.

Common Applications of Internal Gear Pumps

Internal gear pumps are used across a wide range of industries, including:

-

Lubrication Systems: Gear oil, transmission fluid, or hydraulic oil recirculation.

-

Chemical Processing: Resins, polymers, solvents, and acids (with appropriate materials).

-

Food & Beverage: Chocolate, syrup, vegetable oil, and other high-viscosity food-grade fluids.

-

Asphalt & Bitumen Transfer: Ideal for hot, thick fluids requiring high-pressure delivery.

-

Paints & Coatings: Enamel, varnish, and ink that require low shear handling.

Technical Specs and Configuration Options

When specifying an internal gear pump, consider the following:

-

Flow Rate: Ranges from under 1 L/min to over 1,000 L/min depending on size and speed.

-

Pressure: Typically up to 15 bar (217 psi), with some models handling more.

-

Viscosity Range: Can handle fluids from 1 cP (water-like) to over 1,000,000 cP (paste-like).

-

Materials of Construction:

-

Body: Cast iron, stainless steel, or bronze

-

Gears: Steel or composite depending on chemical compatibility

-

Seals: Mechanical, lip, or packing seals

-

-

Mounting: Horizontal baseplate or mobile skid configurations available

Maintenance and Reliability

Internal gear pumps are known for low maintenance needs, but periodic inspection is key:

-

Check for wear on gear teeth and the crescent spacer.

-

Monitor shaft seals for leaks or degradation, especially in high-temp applications.

-

Flush the pump if switching fluids or working with sticky substances.

-

Lubricate bearings per manufacturer guidelines.

With proper care, these pumps can run for thousands of hours with minimal downtime.

Why Choose MultiTorque?

MultiTorque has spent over 15 years helping Australian industries move thick and tricky fluids with precision. Our internal gear pump solutions are backed by hands-on service, high-quality spare parts, and expert advice.

Whether you need a stationary oil transfer unit, a mobile bitumen pump setup, or a food-safe chocolate pump with heat tracing—we’ll make it happen.

Call MultiTorque today on 1300 726 525 or email us at sales@multitorque.com to speak with pump specialists who know what they’re doing.

🔗 Visit: https://www.multitorque.com.au

🔗 Connect on LinkedIn: https://www.linkedin.com/company/multitorque-industries