10 Powerful Reasons High Pressure Centrifugal Pumps Are Game-Changers for Industrial Flow

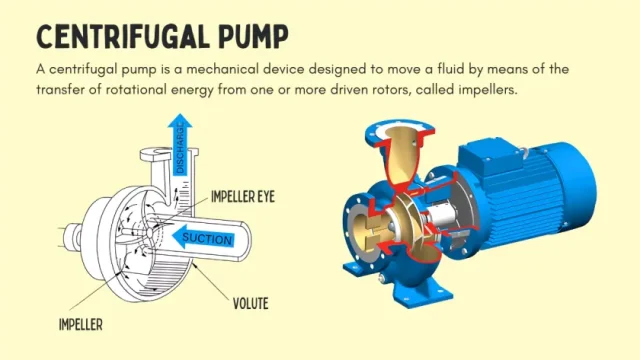

In industrial operations, moving fluids efficiently under demanding conditions isn’t just a goal — it’s a necessity. That’s where high pressure centrifugal pumps come in, offering unmatched power and precision for processes requiring strong pressure and steady flow. Whether it’s water treatment, mining, chemical processing, or fire protection systems, these pumps are designed to deliver performance when it matters most.

Let’s break down the top reasons these pumps dominate in high-demand environments.

1. Unrivaled High-Pressure Capability

High pressure centrifugal pumps are engineered to generate pressures far exceeding standard models—often reaching up to 50 bar (725 psi) or more depending on the design. This makes them ideal for applications requiring strong fluid force to overcome elevation differences, pipe friction, or process requirements.

2. Superior Efficiency at High Flow Rates

Combining robust impellers and optimized volutes, these pumps maintain high hydraulic efficiency even at elevated pressures and flow rates, typically handling anywhere from 10,000 to 50,000 liters per hour. This translates to lower energy costs and reduced operational expenses.

3. Wide Application Range

Industries relying on high pressure centrifugal pumps include:

| Industry | Typical Application | Max Pressure (bar) | Typical Flow Rate (L/hr) |

|---|---|---|---|

| Mining | Slurry transfer, dewatering | 40+ | 20,000+ |

| Chemical Processing | Chemical injection, cooling | 50+ | 10,000+ |

| Water Treatment | Reverse osmosis, filtration | 45+ | 30,000+ |

| Fire Protection | High-pressure firefighting pumps | 40+ | 25,000+ |

4. Robust Construction for Harsh Conditions

Manufactured with high-grade stainless steel, cast iron, or duplex alloys, these pumps resist corrosion, abrasion, and chemical attack. Precision machining ensures tight tolerances for durability and minimal leakage.

5. Customizable to Your Needs

From single-stage to multi-stage configurations, high pressure centrifugal pumps can be tailored for specific pressures, flow rates, and fluid types. MultiTorque specializes in designing custom pump solutions that maximize uptime and efficiency.

6. Reduced Maintenance and Downtime

High quality bearings, seals, and wear-resistant coatings keep these pumps running longer between service intervals. Many models include mechanical seals designed for easy replacement, minimizing downtime and maintenance costs.

7. Compact & Space-Saving Designs

Despite their power, many high pressure centrifugal pumps feature compact footprints, allowing installation in tight industrial spaces without sacrificing performance.

8. Advanced Control & Monitoring

Integration with variable frequency drives (VFDs) and sensors provides precise control over pressure and flow, allowing energy savings and rapid response to process changes. Remote monitoring capabilities keep operations transparent and manageable.

9. Trusted by Industry Leaders

MultiTorque has supplied high pressure centrifugal pumps to dozens of major Australian projects, including mining sites, municipal water plants, and petrochemical facilities. Our expert team supports you from pump selection to installation and ongoing service.

10. Emergency & Backup Solutions

For critical systems like fire protection, we offer redundant pump setups and mobile trailer units that can be deployed rapidly to ensure continuous operation when it counts.

Why Choose MultiTorque for Your High Pressure Centrifugal Pump?

-

15+ years of industry experience

-

Comprehensive range of top-brand pumps

-

Custom engineering and fabrication

-

National coverage with quick support

-

Expert advice tailored to your unique needs

Ready to harness unstoppable pressure and flow? Contact MultiTorque today!

📞 1300 726 525

📧 sales@multitorque.com

🔗 Connect on LinkedIn

MultiTorque: Engineering power, precision, and performance into every pump.