Heavy Duty Air Starters: The Power Behind Industrial Operations 2025

In the world of industrial machinery and equipment, reliability is paramount. When it comes to starting large, powerful engines in tough environments, heavy-duty air starters play an essential role. These systems are designed to provide the necessary force to kickstart engines in demanding conditions, ensuring smooth operations and preventing costly downtime.

What Are Heavy Duty Air Starters?

Heavy-duty air starters are a type of pneumatic starting system that uses compressed air to start engines, particularly in industries such as oil and gas, mining, and marine operations. Unlike traditional electric starters, which rely on electrical current to initiate engine function, air starters leverage the power of compressed air to rotate the engine’s flywheel, beginning the combustion process.

These starters are particularly useful in environments where electrical systems may be impractical or unreliable. Air starters are often found in hazardous areas where sparks could pose a safety risk, and in locations where a power source may be unavailable or inconsistent.

How Do Heavy Duty Air Starters Work?

The mechanics of a heavy-duty air starter are relatively simple. Compressed air is delivered through a valve and into a motor, which then rotates the engine’s flywheel. The process is efficient and reliable, and since it relies on air rather than electricity, it offers significant advantages in certain industrial settings.

The system works by using an air turbine connected to a gear train. As compressed air enters the turbine, it powers the gears, which in turn drive the engine’s starter ring gear. The process of spinning the flywheel kicks off the engine’s ignition process, starting the combustion cycle and enabling the machinery to run.

The key advantages of air starters are their ability to operate in extreme temperatures and harsh conditions. Compressed air doesn’t suffer from the same performance issues that electric starters face in freezing or excessively hot environments, which makes them a preferred option for heavy-duty machinery used in such conditions.

Advantages of Heavy Duty Air Starters

-

Reliability in Harsh Environments

Air starters are designed to handle extreme temperatures and hazardous locations. This makes them ideal for applications in oil and gas rigs, remote mining sites, and marine vessels, where equipment must perform under tough conditions. Since air starters don’t rely on electricity, they are more reliable in environments where electrical systems might fail. -

Safety in Hazardous Locations

For industries where explosive gases or flammable materials are present, using electric starters poses a risk of sparks or electrical failures. Air starters, on the other hand, do not produce sparks, making them a safer alternative in these dangerous environments. -

Power Efficiency

Air starters are known for their power-to-weight ratio. They are lightweight yet incredibly powerful, making them ideal for heavy-duty applications that require significant force to start large engines. Their efficiency allows for more compact designs, freeing up valuable space in industrial machinery. -

Low Maintenance

Compared to electric starters, air starters typically require less maintenance. With fewer moving parts that are prone to wear and tear, air starters can operate for long periods without the need for significant repairs. This contributes to the overall cost-effectiveness of these systems. -

Versatility

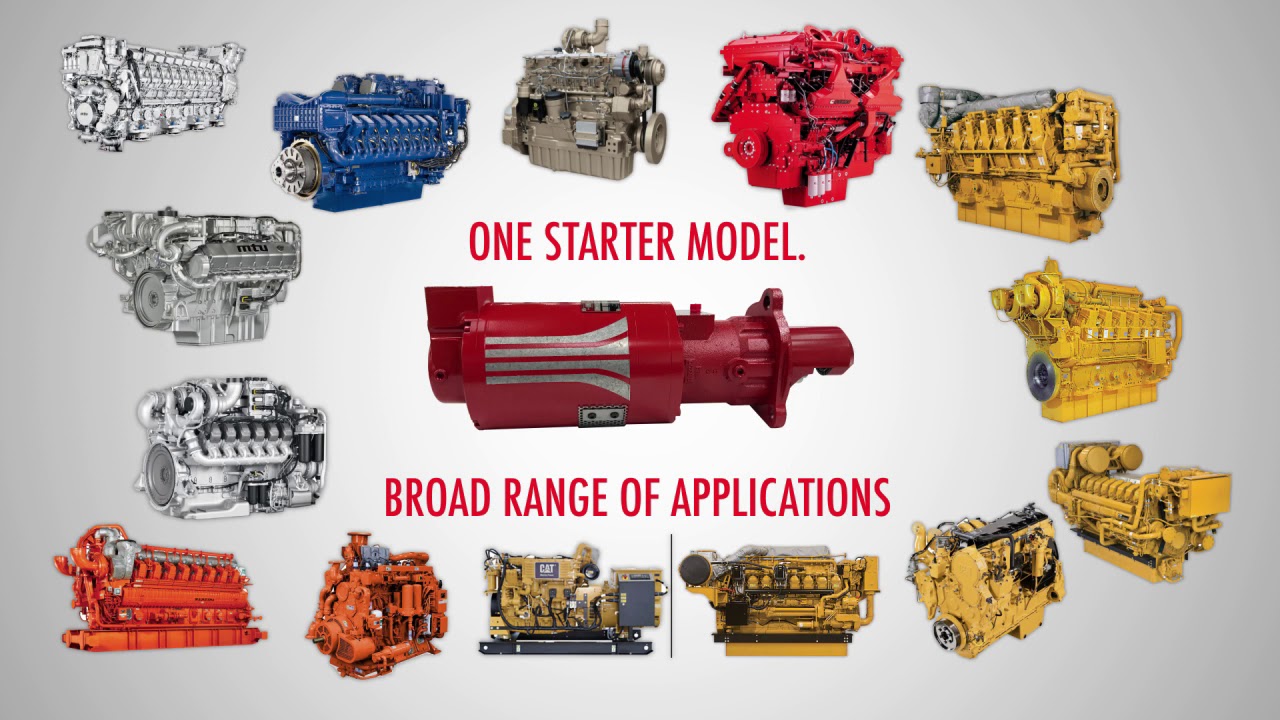

Heavy-duty air starters can be used across a wide range of engine sizes and types. Whether for starting large marine engines, heavy-duty trucks, or industrial generators, these systems provide the flexibility needed to meet various operational needs.

Applications of Heavy Duty Air Starters

Heavy-duty air starters are used in a variety of industries, including:

-

Oil and Gas: Air starters are essential for starting engines in drilling rigs and offshore platforms where reliability and safety are critical.

-

Mining: In mining operations, heavy machinery such as bulldozers and excavators require powerful air starters to function in remote locations where electrical power is limited.

-

Marine: Ships and offshore vessels rely on air starters to ensure the smooth start-up of their engines, even in harsh sea conditions.

-

Power Generation: Air starters are used in power plants to start large turbines and generators, ensuring consistent energy production.

Conclusion

Heavy-duty air starters are a vital component of many industrial operations, providing the necessary power to start engines in the toughest environments. Their reliability, safety, and efficiency make them an essential tool for industries that require machinery to operate smoothly and without interruption. Whether for offshore drilling rigs, mining equipment, or power generation, these air starters are an investment in performance, durability, and safety.

If you’re in need of heavy-duty air starters for your equipment, trust the expertise of MultiTorque. Contact us at 1300 726 525 or sales@multitorque.com for more information and solutions tailored to your specific needs.