Gear Pump Power: 7 Unstoppable Reasons It’s the Backbone of Fluid Control in 2024

🔩 Gear Pump Power: 7 Unstoppable Reasons It’s the Backbone of Fluid Control in 2024

[ez-toc]

When precision meets raw power, you get one elite piece of equipment: the gear pump. If you’re moving oil, fuel, chemicals, or other viscous fluids, a high-quality gear pump delivers unmatched efficiency, reliability, and performance.

At MultiTorque, we don’t just supply gear pumps—we design, build, repair, and upgrade them for industrial legends across Australia. Let’s break down why this mechanical marvel continues to dominate the fluid-handling world.

⚙️ 1. What Is a Gear Pump?

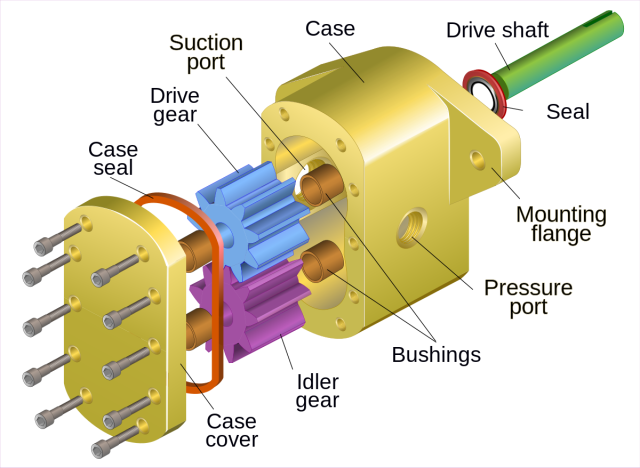

A gear pump is a type of positive displacement pump. It uses two intermeshing gears to transfer fluid by displacement. As the gears rotate, they trap fluid between the gear teeth and the casing, moving it smoothly and with pressure from the suction side to the discharge side.

This simple, rugged design makes gear pumps ideal for:

-

High-pressure applications

-

Viscous fluids like oils, adhesives, or resins

-

Chemical dosing

-

Lubrication systems

🔥 2. Unmatched Pressure & Flow Control

A standard gear pump can deliver pressures of up to 3000 psi (or more, depending on the build) and handle fluids with viscosities up to 100,000 cP. You get a steady, pulseless flow, making it perfect for operations that demand control and consistency.

Whether you’re running hydraulic systems, transferring diesel, or dosing chemicals, this pump type brings you elite performance every time.

🛠️ 3. MultiTorque: Custom Gear Pump Solutions

Cookie-cutter isn’t our style. We manufacture custom gear pump systems mounted on:

-

Trailers

-

Skids

-

Generator-powered modules

-

Stainless or cast-iron frames

-

ATEX or hazardous zone configurations

Whether you’re in mining, oil & gas, agriculture, or manufacturing, MultiTorque can build the exact gear pump system you need—and we’ll do it tough.

💧 4. Gear Pump vs. Centrifugal Pump: Know the Difference

Not sure if you need a gear pump or a centrifugal pump? Here’s the simple breakdown:

| Feature | Gear Pump | Centrifugal Pump |

|---|---|---|

| Flow Type | Constant, positive displacement | Variable, dynamic |

| Ideal For | Thick/viscous fluids | Water and thin liquids |

| Suction Strength | Strong | Moderate |

| Pressure Handling | High | Medium |

When you’re working with oils, polymers, or chemicals, gear pumps win every time.

🔧 5. Full-Service Repairs & Upgrades

Already got a gear pump but it’s underperforming? MultiTorque offers complete overhaul services, including:

-

Gear and casing replacement

-

Seal and bearing servicing

-

Motor retrofits

-

Flow calibration and testing

-

Upgrade to explosion-proof or corrosion-resistant builds

We service all major brands, and we’re happy to redesign existing setups for better performance or compliance.

🔩 6. Gear Pumps for Every Industry

Here’s where you’ll find MultiTorque gear pumps in action:

-

Mining – Lubrication and hydraulic fluid transfer

-

Agriculture – Fertiliser and oil pumping

-

Oil & Gas – Fuel systems and chemical dosing

-

Manufacturing – Adhesives, polymers, and ink transfer

-

Marine – Bilge and engine lubrication pumps

If it needs to flow under pressure, a gear pump is your best mate.

🧠 7. Smart Automation Options

Our custom gear pump systems can be automated and IoT-connected, offering:

-

Pressure sensors

-

Flow meters

-

Remote shutdown and diagnostics

-

Automated VFD control

This isn’t just a pump—it’s a smart industrial tool built for the future.

📞 Talk to the Gear Pump Experts

No fluff. No downtime. Just performance. If you need a gear pump built to work as hard as you do, give MultiTorque a call.

📞 1300 726 525

📧 sales@multitorque.com.au

🌐 www.multitorque.com.au

🔗 LinkedIn – MultiTorque Industries