7 Reasons to Choose MultiTorque for Hydraulic Pump Overhaul 2025

Hydraulic pumps are the heart of many industrial, mining, and agricultural systems. Over time, wear, contamination, and mechanical faults can compromise performance, causing inefficiencies or system failure. MultiTorque offers expert hydraulic pump overhaul services across Australia, ensuring your equipment operates safely, efficiently, and reliably.

With over 15 years of experience, MultiTorque has become a trusted provider of hydraulic pump repairs, servicing, and custom solutions. Our in-house workshops and skilled technicians guarantee top-quality overhauls, restoring pumps to peak performance.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

What Is a Hydraulic Pump Overhaul?

A hydraulic pump overhaul is an in-depth service that restores a pump to its original operating condition. Unlike routine maintenance, overhauls address internal wear, damaged components, and hydraulic inefficiencies.

Core services in a hydraulic pump overhaul include:

- Disassembly, inspection, and cleaning of pump components

- Replacement of worn bearings, seals, and shafts

- Repair or replacement of rotors, pistons, and vanes

- Pressure and flow testing to meet manufacturer specifications

- Custom adjustments for specific operational needs

MultiTorque’s comprehensive approach ensures that your hydraulic pumps perform as efficiently as new equipment, extending operational lifespan and reducing downtime.

Industries That Rely on Hydraulic Pump Overhaul

Hydraulic pumps are critical in sectors requiring precision and reliability:

- Mining & Resources: Powering heavy machinery and slurry transfer systems (see centrifugal pump skid solutions)

- Oil & Gas: Operating drilling rigs, pumps, and hydraulic systems (read about oil and gas pump solutions)

- Chemical Processing: Pumping high-pressure fluids and chemicals safely (read about chemical pump skid systems)

- Manufacturing & Industrial Plants: Hydraulics in presses, lifts, and automated systems

- Agriculture: Irrigation and heavy machinery requiring hydraulic power

A well-executed hydraulic pump overhaul ensures operational continuity, prevents costly breakdowns, and improves overall efficiency.

Common Hydraulic Pump Issues Addressed

MultiTorque technicians specialise in diagnosing and repairing issues commonly encountered in hydraulic pumps:

- Worn Bearings: Leading to vibration, noise, and reduced efficiency

- Seal Failures: Causing leaks and pressure loss

- Rotor or Piston Wear: Reducing pump output and flow consistency

- Contamination Damage: Abrasive particles causing internal wear

- Hydraulic Inefficiencies: Decreasing overall system performance

By addressing these issues, MultiTorque restores hydraulic pumps to optimal condition, helping businesses maintain consistent output and reliability.

Benefits of MultiTorque Hydraulic Pump Overhaul

Choosing MultiTorque for your hydraulic pump overhaul provides several advantages:

- Experienced Technicians: Skilled in a wide range of hydraulic pump types.

- In-House Workshops: Full service without outsourcing ensures quality control.

- Custom Solutions: Tailored overhauls to match operational needs.

- Extended Pump Life: Quality overhauls reduce future breakdowns.

- Minimised Downtime: Rapid service keeps your operations running smoothly.

- Industry Support: Serving mining, oil & gas, chemical, agricultural, and industrial sectors.

Our approach guarantees pumps meet or exceed original manufacturer specifications.

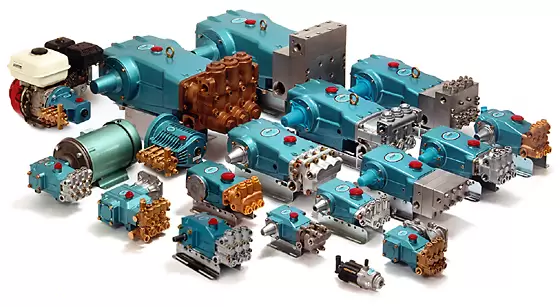

Types of Hydraulic Pumps Serviced

MultiTorque services and overhauls a broad range of hydraulic pumps, including:

- Gear Pumps: High-pressure applications in industrial settings.

- Vane Pumps: Smooth, quiet operation for precision systems.

- Piston Pumps: High-performance pumps for demanding hydraulic systems.

- Custom Industrial Pumps: Designed for specialised applications.

- Skid-Mounted Systems: Integrated solutions for complex operations (read more about progressive cavity pumps).

Every pump is carefully inspected and repaired to ensure maximum efficiency, reliability, and longevity.

Maintenance Tips to Extend Hydraulic Pump Life

Post-overhaul care is essential to prolong pump life:

- Regularly check and replace hydraulic fluid

- Monitor operating pressures and flow rates

- Inspect seals, bearings, and shafts for wear

- Keep systems clean to prevent contamination

- Schedule routine inspections and professional servicing

MultiTorque provides expert guidance and in-house servicing to keep hydraulic pumps running efficiently for years to come.

Why Choose MultiTorque

MultiTorque is Australia’s trusted expert in hydraulic pump overhaul because of:

- Experience: Over 15 years repairing and servicing industrial and mining pumps.

- Technical Expertise: Knowledge of gear, piston, and vane pumps.

- In-House Workshop: Complete overhaul services without outsourcing (read more about Mono pump solutions).

- Nationwide Support: Perth and Brisbane branches ready to handle urgent repairs.

- Customer-Focused: Commitment to reliability, efficiency, and long-term client relationships (see NOV Mono pump systems).

Partnering with MultiTorque ensures your hydraulic pumps are repaired efficiently, safely, and professionally.

Contact MultiTorque

For professional hydraulic pump overhaul services in Australia, contact MultiTorque today. Our team will evaluate your pumps, provide expert solutions, and restore them to peak performance.

📞 Phone: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque Industries

Trust MultiTorque for durable, efficient, and reliable hydraulic pump overhauls that keep your operations running smoothly.