Dewatering Mud Pumps – Built to Handle Australia’s Toughest Jobsites 2025

When water mixes with soil, clay, or drilling cuttings, it creates thick slurry that’s a nightmare for most pumps—but not for a well-built dewatering mud pump. In mining, civil works, and tunnelling, dealing with mud and slush is an everyday challenge. That’s why you need rugged, solids-handling pumps designed specifically for the job.

At MultiTorque, we supply, service, and customize dewatering mud pumps that are trusted across Australia. Whether you’re draining a flooded trench, moving drilling fluid, or managing slurry in a processing plant, we’ve got a pump system that performs—no excuses.

What Is a Dewatering Mud Pump?

A dewatering mud pump is a type of heavy-duty industrial pump designed to remove water that contains mud, sand, silt, and other abrasive solids. Unlike standard water pumps, these systems are built with wear-resistant components and large clearances to handle high-viscosity fluids and slurries without clogging or failing.

At MultiTorque, our mud pumps come in a variety of formats, including:

- Centrifugal slurry pumps

- Diaphragm pumps (air or engine driven)

- Electric submersible trash pumps

- Diesel-powered trailer units

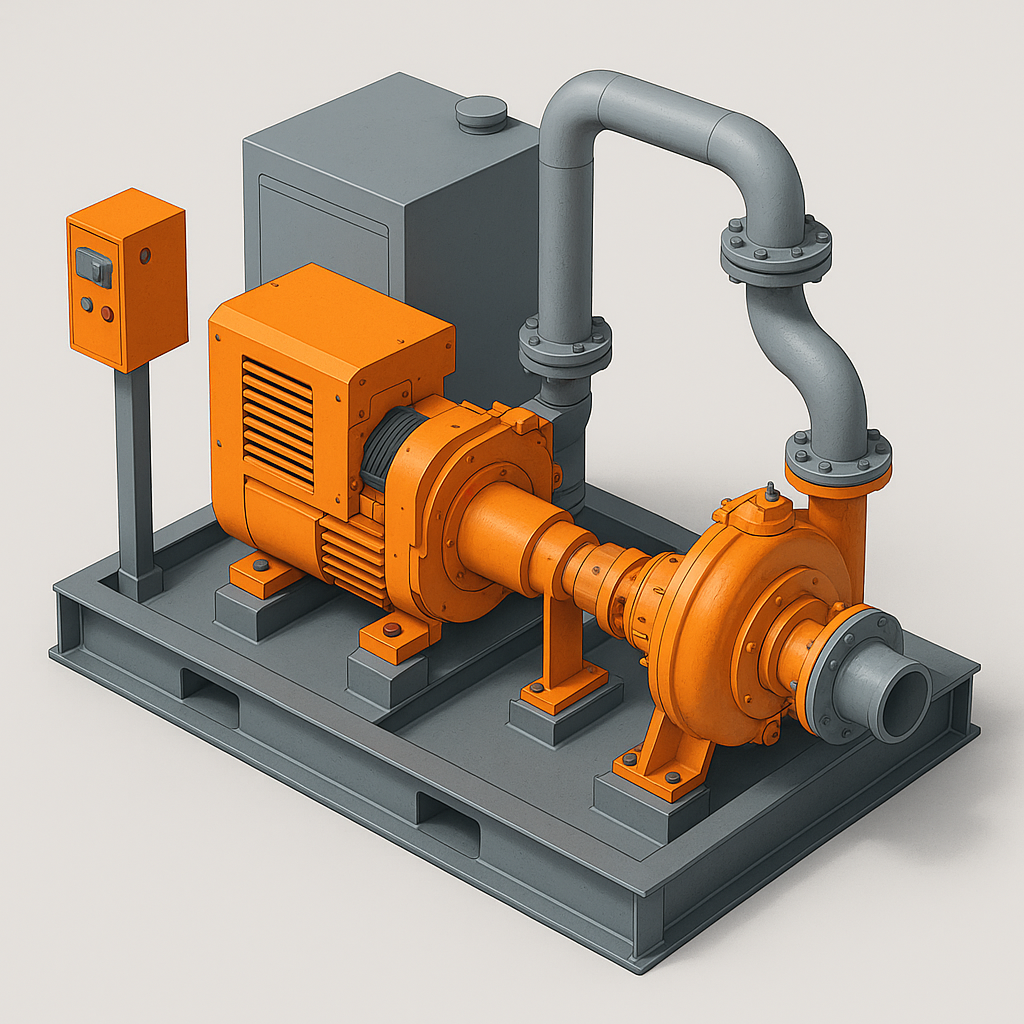

- Skid-mounted dewatering systems

Each unit is selected based on your required flow rate, head pressure, solids content, and mobility needs.

Where Are Dewatering Mud Pumps Used?

Our pumps are in service across Australia in projects that demand serious solids-handling:

- Open-cut and underground mining

- Drilling operations (oil, gas, and water)

- Civil excavation and tunnelling

- Quarry pits and slurry ponds

- Flood recovery zones

- Agricultural runoff management

If your operation involves thick, muddy water or fluid with suspended solids, a standard pump just won’t survive. That’s where a dewatering mud pump comes into its own.

Key Features of MultiTorque’s Mud Pumps

✔ Solids Handling: Our pumps are designed to handle solids up to 75mm in size, perfect for slurry, bentonite, or sludge.

✔ Abrasion Resistance: Components like hardened impellers, rubber-lined casings, and heavy-duty seals ensure long service life.

✔ Mobility Options: Available as trailer-mounted, IBC-mounted, or skid-based systems for on-site flexibility.

✔ Power Variants: Choose from electric, diesel, or air-operated units depending on your site’s infrastructure.

✔ Custom Builds: Need a solution tailored to your pit depth, slurry thickness, or flow range? We can design and build it.

Service That Keeps You Pumping

At MultiTorque, we don’t just sell pumps—we support them for life. Our service centres in Brisbane and Perth are equipped for:

- Full pump rebuilds and diagnostics

- Impeller and seal replacements

- Emergency breakdown repairs

- Preventative maintenance programs

- Rapid parts dispatch Australia-wide

We understand how downtime affects productivity, especially when mud is backing up. Our goal is to keep your operation flowing smoothly—no matter the mess.

Trusted Brands We Work With

We only supply proven pump brands that thrive in Australia’s most demanding worksites, including:

- Wilden (air-operated diaphragm pumps)

- Napco

- Orbit slurry pumps

- Atlas Copco trash pumps

- NOV Mono progressive cavity systems

Need help matching the right pump to your project? Our team will spec it out, supply it, and keep it working.

Why Choose MultiTorque?

- Over 15 years of hands-on industry experience

- Customised mud pumping systems

- Fast response times and honest advice

- Extensive stock of spares and parts

- Friendly, expert support you can trust

We build long-term relationships with mining contractors, civil engineers, and service crews—because we know reliability matters.

Get the Right Dewatering Mud Pump Now

Don’t let sludge slow you down. MultiTorque has the gear, the team, and the know-how to handle your toughest dewatering challenges.

📞 Call us today on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Connect on LinkedIn: MultiTorque LinkedIn