Custom Pump Design Services for Industrial Applications | MultiTorque Australia 2025

When off-the-shelf pumps don’t cut it, you need a solution that fits your system—not the other way around. That’s where custom pump design comes in.

When off-the-shelf pumps don’t cut it, you need a solution that fits your system—not the other way around. That’s where custom pump design comes in.

At MultiTorque, we engineer and deliver made-to-order pump systems that meet the specific flow rates, pressures, fluids, and operating conditions your project demands. With workshops in Perth and Brisbane, and over 15 years of industry experience, we’re trusted by Australia’s leading sectors for high-performance, custom-built pump solutions.

What is Custom Pump Design?

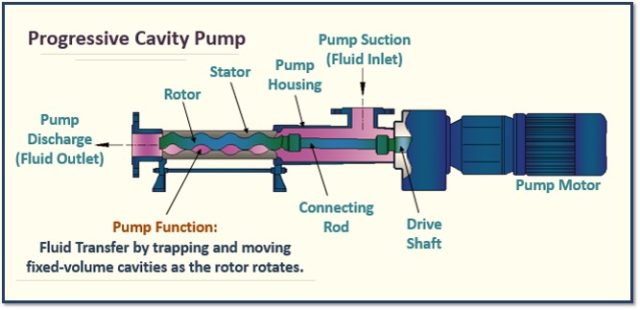

Custom pump design is the process of engineering a pump or pumping system from the ground up to suit your unique operating environment. Instead of modifying existing pumps or making compromises, MultiTorque builds the system around your needs—whether it’s flow rate, fluid type, space restrictions, or environmental factors.

Our designs are tailored for optimal:

-

Efficiency

-

Durability

-

Safety

-

Serviceability

-

Cost-effectiveness

From impeller selection to drive system configuration, we cover every detail.

Industries We Serve

Custom pump design is critical across many Australian industries:

-

Mining & Dewatering: Slurry handling, groundwater management, high-pressure fluid transfer

-

Agriculture: Fertigation, irrigation, and water recycling

-

Oil & Gas: Chemical dosing, fuel transfer, and high-viscosity fluid movement

-

Water Treatment: Wastewater processing, stormwater pumping, clean water delivery

-

Manufacturing: Process cooling, heat exchange, and material handling

If your operation requires reliability under tough or niche conditions, a custom-designed pump is the smartest long-term investment.

Our Custom Design Process

At MultiTorque, we follow a step-by-step process to ensure each pump meets the highest standards:

-

Needs Analysis

We work with you to understand your fluid characteristics, duty cycle, head requirements, NPSH considerations, and space constraints. -

Design & Engineering

We use CAD and simulation software to design pumps with the optimal materials, impeller geometry, and drive options. -

Component Selection

We integrate trusted brands like Wilden, NOV, Orbit, Grundfos, and Napco, ensuring quality from inlet to outlet. -

Fabrication & Assembly

Our in-house team builds custom skids, frames, control panels, and trailer mounts as needed. -

Testing & Commissioning

Before delivery, your pump is tested under simulated load conditions to guarantee performance. -

Installation & Aftercare

We offer full setup support and ongoing service, so your system keeps running at full capacity.

Why Choose Custom Over Standard?

Off-the-shelf pumps might be convenient—but they’re rarely ideal. Choosing custom pump design can:

-

Improve efficiency and lower operating costs

-

Prevent breakdowns due to mismatched components

-

Handle harsh fluids like abrasive slurries or corrosive chemicals

-

Fit tight or complex system layouts

-

Meet strict safety or compliance standards

It’s not about luxury—it’s about longevity and performance.

Custom Skid & Trailer-Mounted Pump Builds

Need mobility or modularity? We also design trailer-mounted and skid-based pump systems for remote or temporary operations.

Popular with mining, construction, and agriculture clients, these builds offer:

-

Easy transport between sites

-

Plug-and-play functionality

-

Weather-resistant housings

-

Diesel, electric, or air motor compatibility

Whether you’re managing site water, tailings, or fuel transfer, our mobile pump solutions are built to last.

Partner With MultiTorque

MultiTorque is more than a pump supplier—we’re a solutions provider. Our team doesn’t just sell equipment; we engineer systems that solve real-world problems. Whether you need a fully custom pump from scratch or a tailored modification of an existing setup, we’re ready to build it with precision.

📞 1300 726 525

📧 sales@multitorque.com

🌐 www.multitorque.com.au

🔗 Follow us on LinkedIn

MultiTorque — Custom-built pump systems designed for real-world demands.