Centrifugal Pump Pump Power: 7 Reasons It Dominates Industrial Fluid Flow in 2024

💥 Centrifugal Pump Pump Power: 7 Reasons It Dominates Industrial Fluid Flow in 2024

When it comes to moving fluids fast and efficiently, the centrifugal pump pump reigns supreme. You read that right — this is the pump so good, we said it twice. Whether you’re in mining, agriculture, wastewater, or manufacturing, this workhorse delivers unmatched flow, reliability, and adaptability.

At MultiTorque, we don’t just supply centrifugal pump pumps — we also repair, service, and manufacture custom systems for every scenario you can throw at us.

This guide gives you 7 big reasons why the centrifugal pump pump is still the king of the industrial jungle in 2024.

⚙️ 1. What Is a Centrifugal Pump Pump?

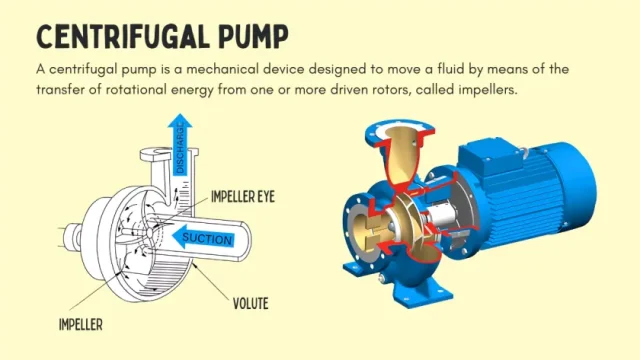

A centrifugal pump pump is a mechanical device that uses rotational energy to move fluids through a system. It converts kinetic energy from a motor into pressure that propels liquid forward. The “pump pump” phrasing emphasizes the compound use of centrifugal systems, often where dual-stage or twin-pump configurations are used for extra power.

MultiTorque supplies both single-stage and multistage centrifugal pumps, built to spec or pulled from our trusted inventory of brands like NOV, Napco, Wilden, and more.

🚀 2. Ultra-High Flow Rates (Up to 30,000+ LPM)

Centrifugal pump pumps are famous for their ability to move massive volumes of fluid fast. Depending on your system’s design, you can expect flow rates exceeding 30,000 litres per minute. That’s why they’re used in:

-

Irrigation

-

Large-scale dewatering

-

Municipal water handling

-

Industrial transfer lines

If it’s big, wet, and needs to move fast — this is your solution.

🧠 3. Simple Design = Less Downtime

Centrifugal pump pumps have a straightforward design: a motor, an impeller, and a volute. Fewer moving parts means less maintenance, lower operating costs, and increased lifespan.

At MultiTorque, we offer preventative maintenance plans, on-site servicing, and rapid-response repair to keep your operations running smoothly.

🛠️ 4. MultiTorque Custom Builds = Next-Level Power

Need a centrifugal pump pump mounted to a trailer, truck, skid, or container? No problem. Need it powered by diesel, electric, or solar? Easy. Want a dual-pump system for redundancy or flow boosting? Let’s do it.

We engineer custom solutions for mining camps, water treatment sites, and rural properties. Just bring your specs or tell us your flow rate and head height — we’ll handle the rest.

🌐 5. Applications Across Every Industry

Centrifugal pump pumps are found everywhere:

-

Agriculture – Crop irrigation, fertigation, dam transfers

-

Mining – Pit dewatering, slurry handling (with specific linings)

-

Oil & Gas – Cooling circuits, condensate transfer

-

Construction – Groundwater removal, supply distribution

-

Commercial – HVAC systems, water supply, and drainage

If your job deals with liquid, there’s a cent pump solution.

🔁 6. Repair, Replace, or Upgrade — We’ve Got You

We don’t just drop off a box and disappear. MultiTorque offers full lifecycle support:

-

On-site pump inspections

-

Seal and bearing replacements

-

Motor rewinds and replacements

-

Flow testing and system diagnostics

-

Spare parts sourcing for all major makes

You’ll get real support, real expertise, and a team that’s been in the game for 15+ years.

🧲 7. Why “Pump Pump”? Dual Systems for Bigger Jobs

Some sites require double pump systems — for redundancy, higher lift, or boosted flow. In those cases, it’s literally a centrifugal pump… connected to another pump. We call this configuration a “pump pump” — and it’s more common than you think, especially in remote mining, flood response, and tank farms.

Our engineers can design and fabricate custom dual-pump systems with smart logic, flow control, and failover protection.

🔥 Power Your Site With MultiTorque

Need a centrifugal pump pump solution that performs under pressure?

Call the experts who live and breathe industrial flow.

📞 1300 726 525

📧 sales@multitorque.com.au

🌐 www.multitorque.com.au

💼 Follow us on LinkedIn