CAT Pump Maintenance: Keep Your Equipment Running Longer – MultiTorque 2025

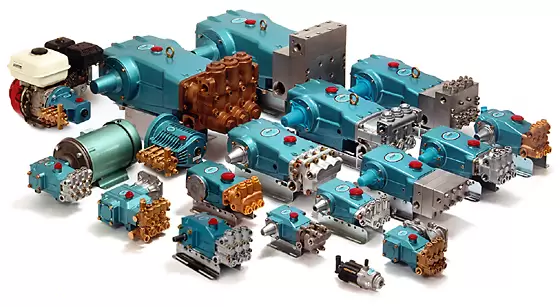

CAT Pump Maintenance: When it comes to reliable, high-pressure pumping solutions, CAT Pumps are among the most trusted names in the industrial world. Known for their durability and precision, these positive displacement pumps are commonly used across industries like mining, manufacturing, car washes, oil & gas, and more. However, even the best pumps need proper upkeep to function at peak performance — and that’s where CAT pump maintenance becomes critical.

At MultiTorque, we don’t just supply high-quality CAT pumps — we also offer expert CAT pump service, repair, and maintenance across Australia. Here’s your guide to keeping these rugged machines in top condition.

Why CAT Pump Maintenance Matters

Regular maintenance prevents costly downtime, extends equipment life, and helps maintain maximum efficiency. Neglecting CAT pump maintenance can result in:

-

Seal or valve failure

-

Loss of pressure

-

Excessive noise or vibration

-

Overheating

-

Reduced flow rate

Whether you’re running a CAT triplex piston pump in a wash-down application or a custom skid-mounted CAT unit in an industrial setting, consistent servicing is key to keeping it working hard — and smart.

Key Components to Monitor

CAT pumps are precision-engineered machines. Proper maintenance requires attention to specific wear components, including:

-

Plungers and Seals: Check for leakage or scoring. These should be replaced before full failure.

-

Inlet and Discharge Valves: Inspect for wear or blockage.

-

Crankcase Oil: Change every 500 hours or as per OEM recommendations.

-

Drive Belts and Couplings: Ensure proper alignment and tension.

-

O-rings and Gaskets: Check for signs of cracking or wear.

MultiTorque offers genuine CAT replacement parts and repair kits, ensuring your system gets OEM-quality care every time.

CAT Pump Maintenance Checklist

Here’s a basic preventive maintenance schedule:

Daily:

-

Inspect for leaks

-

Check for unusual noise or vibration

-

Verify pressure and flow consistency

Weekly:

-

Check oil level and color

-

Inspect filters and strainers

Monthly:

-

Change crankcase oil if not already done

-

Check condition of plungers, seals, and valves

-

Tighten bolts and mounts

Every 500 Hours:

-

Full inspection and service by a qualified technician

-

Replace worn seals and components

For businesses with continuous or heavy-duty operations, MultiTorque offers scheduled maintenance packages to keep everything on track.

CAT Pump Repair Services at MultiTorque

If something does go wrong, our experienced team can get you back in action fast. We offer:

-

On-site pump diagnostics and troubleshooting

-

In-house CAT pump rebuilds

-

Fast turnaround on urgent jobs

-

Custom skid unit repairs and upgrades

We also handle emergency breakdowns and provide loan units in select cases, reducing your downtime to the absolute minimum.

Why Choose MultiTorque?

With over 15 years of industry experience, MultiTorque is trusted by businesses across Australia for their CAT pump service, supply, and repairs. Whether you’re located in Brisbane, Perth, or operating remotely, we’ve got the tools, parts, and know-how to support your operation.

We also work with other top-tier pump brands like Wilden, Orbit, and NOV, offering full-spectrum industrial pumping solutions.

Contact Us

Don’t wait for a breakdown. Keep your CAT pump running strong with professional maintenance and servicing from MultiTorque.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

https://www.linkedin.com/company/3176927