Air Starter Diesel Engine: Reliable Starting Solutions for Heavy-Duty Applications 2025

Diesel engines power a significant portion of heavy machinery, trucks, marine vessels, and industrial equipment worldwide. One critical component that ensures these engines operate smoothly is the air starter—a specialized device designed to initiate engine operation efficiently and reliably. This article delves into the concept of air starter diesel engines, explaining what they are, how they work, their advantages, applications, and maintenance tips. Whether you’re an industry professional or simply curious about engine technologies, this guide covers everything you need to know about air starters in diesel engines.

What is an Air Starter Diesel Engine?

An air starter is a pneumatic device that uses compressed air to start large diesel engines, especially those too big or high-torque for traditional electric starters. Unlike conventional electric starters, air starters deliver torque by using compressed air to spin the engine’s flywheel, providing the initial motion needed to ignite the diesel engine.

How Does an Air Starter Work?

The air starter operates by directing compressed air into a turbine or vane motor. This motor converts the air pressure into rotational force, spinning the engine’s flywheel and crankshaft. Once the engine reaches a sufficient speed, fuel injection and combustion begin, and the engine runs on its own.

There are two common types of air starters used with diesel engines:

- Vane Type Air Starters: Use rotating vanes inside a cylindrical housing to convert compressed air into mechanical rotation. Known for high torque and durability.

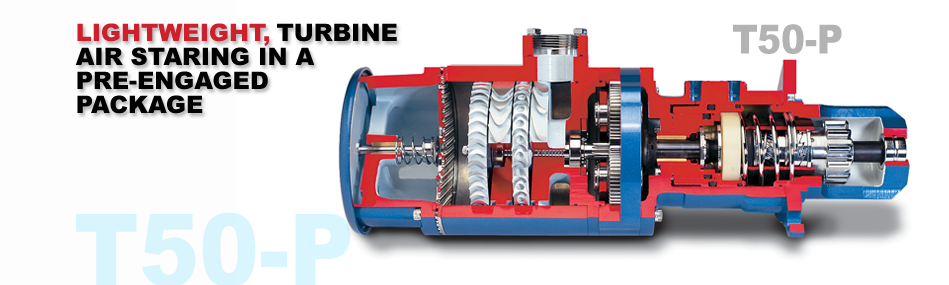

- Turbine Type Air Starters: Use a turbine wheel turned by compressed air; typically lighter and faster but produce less torque than vane starters.

Advantages of Using Air Starters in Diesel Engines

1. High Reliability

Air starters are renowned for their simple design and robust construction, making them highly reliable in harsh industrial and marine environments. Since they don’t rely on electric components, they are less prone to failure caused by moisture, corrosion, or electrical faults.

2. Powerful Torque Output

Air starters deliver high starting torque, ideal for large diesel engines that require significant power to crank. This is particularly beneficial for engines used in heavy machinery, marine vessels, and power generation.

3. Safety Benefits

Compressed air systems reduce risks associated with electrical sparks or battery failures, making air starters safer to use in explosive or hazardous environments such as oil rigs and mining sites.

4. Ease of Maintenance

With fewer moving parts and no electrical components, air starters typically require less maintenance than electric starters. Regular lubrication and inspection of air lines and seals are usually sufficient.

5. Lightweight and Compact

Air starters tend to be lighter and more compact than electric starters with comparable torque, helping reduce the overall weight of the engine assembly.

Common Applications of Air Starter Diesel Engines

1. Marine Engines

Large marine diesel engines powering cargo ships, fishing vessels, and passenger ferries often use air starters. Their reliability and safety make them suitable for maritime environments.

2. Mining and Heavy Equipment

Mining trucks, excavators, and other heavy machinery employ air starters to handle the high torque required to start their massive engines under tough conditions.

3. Power Generation

Diesel generators used for power plants or backup electricity rely on air starters for quick and dependable starts during outages or emergencies.

4. Oil and Gas Industry

Due to hazardous environments, oil rigs and refineries prefer air starters over electric ones to minimize fire and explosion risks.

Choosing the Right Air Starter for Your Diesel Engine

Selecting the right air starter involves considering several factors:

- Engine Size and Torque Requirements: Larger engines require starters capable of delivering higher torque.

- Starting Air Pressure: Compatibility with the available compressed air supply is crucial.

- Duty Cycle: Frequency and duration of engine starts will influence the starter type and size.

- Environmental Conditions: Consider corrosion resistance and temperature tolerance based on where the engine operates.

- Maintenance Accessibility: Ease of servicing the starter in your specific application.

Installation and Maintenance Tips

Proper installation and maintenance of air starters extend their lifespan and ensure consistent performance:

Installation

- Follow manufacturer guidelines closely for mounting and alignment.

- Use clean, dry, and lubricated compressed air to prevent damage.

- Ensure air filters and regulators are installed to maintain air quality.

Maintenance

- Regularly inspect air lines for leaks or damage.

- Lubricate moving parts as recommended by the manufacturer.

- Check seals and gaskets periodically to avoid air loss.

- Test starter operation during routine engine maintenance.

Troubleshooting Common Air Starter Issues

Despite their reliability, air starters may face issues such as:

- Insufficient Torque: Could be due to low air pressure, clogged filters, or worn vanes.

- Slow Cranking: Air leaks or improper lubrication may cause slow rotation.

- Starter Motor Overheating: Often caused by prolonged cranking or lack of lubrication.

- Failure to Engage: May be related to faulty control valves or damaged internal components.

Regular inspections and timely repairs can prevent these problems from escalating.

Why Choose MultiTorque for Your Air Starter Diesel Engine Needs?

At MultiTorque Industries, we specialize in supplying and servicing top-quality air starters and related components for diesel engines across Australia. With over 15 years of industry experience, we provide:

- Trusted brands and durable, high-performance equipment.

- Custom solutions tailored to your specific engine and operational needs.

- Expert advice, installation support, and reliable after-sales service.

- Fast turnaround times to minimize downtime for your equipment.

Whether you operate in mining, marine, construction, or power generation, MultiTorque has the right air starter solutions to keep your diesel engines running smoothly.

Conclusion

The air starter diesel engine combination is essential in powering heavy-duty machinery, marine vessels, and industrial equipment efficiently and safely. Air starters provide a reliable, powerful, and low-maintenance starting solution suited for challenging environments. Choosing the right air starter and maintaining it properly can save you time, money, and avoid costly downtime.

If you’re looking for quality air starters, expert guidance, or custom solutions tailored to your diesel engine needs, contact MultiTorque Industries today at 📞 1300 726 525 or visit www.multitorque.com.au for more information. https://www.linkedin.com/company/3176927

Air Starter Diesel Engine

Air Starter Diesel Engine

Air Starter Diesel Engine