When it comes to keeping your job site dry and operational, there’s no room for equipment failure. Whether you’re draining a flooded excavation site, managing groundwater in a mine, or handling heavy runoff at a construction zone, industrial dewatering pumps are your first line of defence.

At MultiTorque, we supply, service, and custom-build dewatering pump systems that thrive in Australia’s harshest conditions. With workshops in Brisbane and Perth and clients across mining, civil, agriculture, and utilities—we deliver reliability when it matters most.

What Are Industrial Dewatering Pumps?

Industrial dewatering pumps are high-capacity pumps designed to remove water—often dirty, abrasive, or chemically reactive—from worksites, pits, or machinery zones. They’re used in a wide range of industries to:

-

Prevent flooding

-

Manage stormwater runoff

-

Remove groundwater or slurry

-

Drain tanks or vessels

-

Maintain dry work areas for safe operations

These pumps must be powerful, portable, and durable enough to withstand non-stop duty in tough conditions.

Types of Dewatering Pumps We Supply and Service

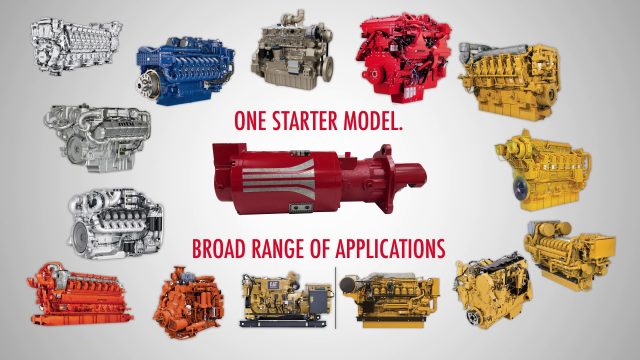

At MultiTorque, we work with all major types of industrial dewatering pumps, including:

-

Centrifugal pumps – Ideal for moving large volumes quickly

-

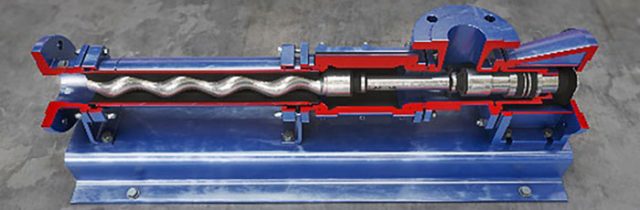

Submersible pumps – Designed to operate fully submerged in pits or tanks

-

Diesel-driven pumps – Perfect for remote sites with no grid access

-

Trailer-mounted pump systems – Fully mobile for flexible use

-

High-head pumps – For vertical lifts and long discharge lines

-

Slurry-capable pumps – Built to handle thick or abrasive materials

We also supply pumps with electric or solar power options, depending on your site’s needs.

Custom Dewatering Pump Trailers

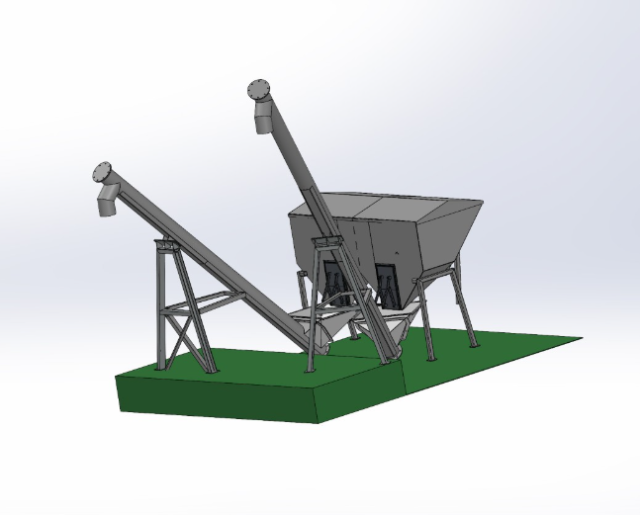

Need a mobile pumping unit built to spec? We manufacture custom pump trailers right here in Australia.

Whether you need a single high-flow unit or a multi-pump rig with onboard fuel, lighting, and control panels—we’ll build it. Our mobile dewatering trailers are ideal for:

-

Mine dewatering

-

Flood response and emergency pumping

-

Construction site water control

-

Irrigation and agriculture drainage

-

Remote infrastructure works

Tell us your flow rate, lift height, and site conditions—we’ll deliver a solution that lasts.

Industries That Rely on Dewatering Pumps

We supply and service dewatering equipment for clients in:

-

Mining and quarrying

-

Oil & gas

-

Construction and civil

-

Agriculture and irrigation

-

Utilities and water treatment

-

Transport and logistics

From iron ore pits to farmland flood zones, our industrial dewatering pumps are engineered for non-stop performance.

Top Brands We Support

We work with proven, high-performance dewatering pump brands including:

-

NOV

-

Orbit

-

Wilden

-

Grundfos

-

Cat Pumps

-

Tuthill

-

Napco

We supply genuine parts, perform full repairs, and can even upgrade or retrofit your existing setup for greater efficiency.

Why Choose MultiTorque?

Here’s why clients across Australia trust MultiTorque for industrial dewatering systems:

-

Fast service and support across Brisbane, Perth & beyond

-

Custom builds tailored to your application

-

Field servicing and workshop repairs

-

Genuine parts and high-quality components

-

Over 15 years of hands-on industry experience

-

No-fuss warranties and transparent pricing

We know the cost of downtime—so we build to prevent it.

Ready to Keep Your Site Dry?

When it comes to industrial dewatering pumps, don’t settle for second-best. MultiTorque builds, supplies, and services pumps that perform under pressure—because your site can’t afford to stand still.

📞 Call us now on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 Connect on LinkedIn: MultiTorque LinkedIn

Let us design the right pump system for your site—and keep your project flowing.