The 5.9 Cummins diesel engine is known for its reliability, torque, and long service life in demanding applications like mining, transport, agriculture, and power generation. While many rely on electric starters, there’s a growing demand for an air starter for the 5.9 Cummins—especially in environments where safety, reliability, and cold-start performance are critical.

Whether you’re operating in remote locations or hazardous areas where electric sparks are a risk, an air starter can be the smarter solution. Here’s everything you need to know.

Why Use an Air Starter on a 5.9 Cummins?

The 5.9L Cummins diesel engine is used in a variety of platforms including industrial machinery, marine generators, and heavy-duty work trucks. Electric starters work well under normal conditions—but in applications that demand reliable cold starts, spark-free ignition, or extended durability, switching to an air starter can be a game-changer.

Key Benefits:

- No Electrical Dependence

No need to rely on batteries—perfect for isolated work sites, remote mining, or marine applications. - Spark-Free Operation

Essential in flammable or hazardous environments like fuel depots, oil rigs, and underground operations. - Rugged Design

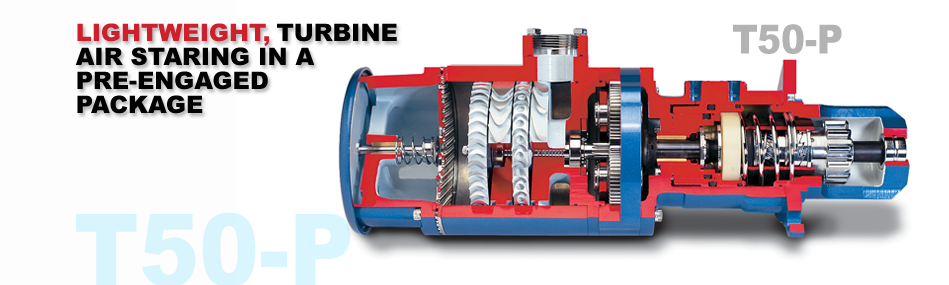

Air starters are built tough, reducing downtime and maintenance frequency. - Lightweight & Powerful

High torque output allows it to turn over the 5.9 Cummins reliably, even in extreme cold or after engine rest periods.

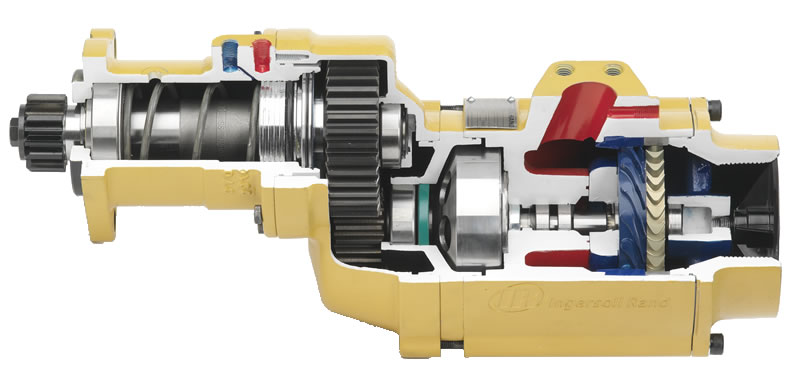

How Does an Air Starter Work?

Air starters use compressed air to drive a small turbine or piston mechanism that cranks the engine. For the 5.9 Cummins, an air starter is mounted similarly to an electric one but connects to a compressed air supply (usually from an onboard air tank or external source).

Air is delivered at high pressure—typically 100–150 PSI—and engages the starter pinion to turn the flywheel. Once combustion is initiated, the air system disengages, and the engine runs as normal.

🛠️ Explore MultiTorque’s full range of air and gas starters

Applications for Air Starters on the 5.9 Cummins

Here are some of the most common use cases where air starters outperform traditional systems:

- Underground mining trucks and loaders

- Marine gensets running 5.9 Cummins engines

- Fuel tankers and explosive cargo haulers

- Remote agricultural operations with no grid access

- Backup generators for off-grid infrastructure

When spark risk, battery failures, or extreme weather make electric starters unreliable, air becomes the preferred choice.

Choosing the Right Air Starter for a 5.9 Cummins

Not all air starters are made equal. You’ll want to consider:

- Mounting Compatibility – Ensure the starter matches your Cummins bellhousing.

- Torque Output – Choose a unit powerful enough to handle your specific compression ratio and conditions.

- Serviceability – Opt for a unit supported by local suppliers like MultiTorque for maintenance, parts, and tech support.

- Air Supply – Confirm you have a compressed air system with sufficient PSI and volume.

🧰 Need a custom solution or help with fitment? Contact MultiTorque’s engineering team

Why MultiTorque Is the Trusted Name in Air Starters

With over 15 years of experience, MultiTorque supplies and services air starters for a wide range of diesel engines—including the 5.9 Cummins. Whether you’re retrofitting, upgrading, or replacing a failed starter, we provide:

- Direct-fit air starter units for Cummins applications

- Custom air start systems with tanks, lines, and valves

- Expert tech support and fitment advice

- Fast shipping Australia-wide

📞 Call 1300 726 525 or ✉️ email sales@multitorque.com to speak with our team.

🔗 Follow us on LinkedIn for product updates and industry tips

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins

Air Starter for 5.9 Cummins