The term mono pomp is often used to describe a type of progressive cavity pump widely used in various industries for its ability to handle viscous, abrasive, and shear-sensitive fluids. While the spelling “mono pomp” may be less common, it refers to the same dependable technology that many Australian industries rely on for consistent fluid transfer.

In this article, we’ll explore what a mono pomp is, where it’s used, the benefits it offers, and how MultiTorque provides repair, servicing, and supply options across Australia.

What Is a Mono Pomp?

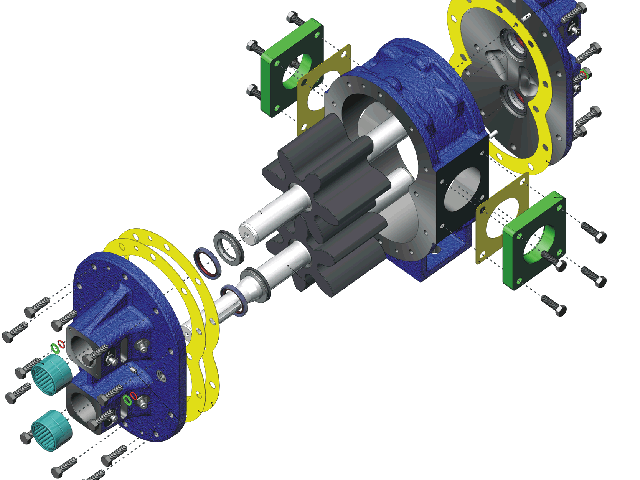

A mono pomp (also known as a progressive cavity pump) is a type of positive displacement pump that works by transferring fluid through a sequence of small, fixed-shape cavities. These cavities are formed between a helical rotor and a stator. As the rotor turns, the fluid is gently and continuously moved from the pump’s suction to discharge side.

This design makes the mono pomp ideal for transferring fluids that are:

- Highly viscous

- Contain solids or slurry

- Shear-sensitive

- Abrasive

- Or prone to foaming

Unlike centrifugal pumps, mono pomps maintain a constant flow rate regardless of pressure variations, making them ideal for applications where precision and consistency are crucial.

Common Applications of Mono Pomps

Due to their versatility and efficiency, mono pomps are found in a wide variety of sectors across Australia, including:

- Mining & Dewatering: For slurry and tailings transfer

- Wastewater Treatment: For sludge handling and chemical dosing

- Oil & Gas: For transferring drilling muds and other viscous fluids

- Agriculture: In manure systems and irrigation setups

- Food & Beverage: For pumping thick pastes, pulps, or liquids with solids

- Industrial Manufacturing: In adhesives, paint, and resin handling

Because mono pomps can handle difficult fluids while delivering consistent performance, they are often chosen for tough environments where other pumps fail.

Why Choose a Mono Pomp?

Businesses often select mono pomps over other pump types due to these major benefits:

- Smooth, Pulsation-Free Flow – Ideal for sensitive applications

- High Suction Lift Capabilities – Can draw fluid from significant depths

- Versatility – Effective with fluids of almost any viscosity

- Energy Efficient – Requires less energy in high-viscosity applications

- Self-Priming – Can run dry for short periods without damage

These advantages make mono pomps one of the most flexible pumping solutions on the market.

Mono Pomp Repairs and Servicing by MultiTorque

At MultiTorque, we’re specialists in the service, repair, and supply of mono pomps across Australia. With over 15 years of experience and branches in Perth and Brisbane, we support industries that rely on continuous, trouble-free pumping operations.

Our services include:

- Workshop & On-Site Repairs – Whether you bring your unit to us or need field support, we deliver fast turnaround times.

- Genuine & Aftermarket Parts – We stock quality components for most mono pump brands.

- Pump Overhauls – Full refurbishment including stator, rotor, seals, and bearing assemblies.

- System Audits – Ensure your mono pomp is correctly sized and configured for your process.

- Custom Mounting Options – Trailer- or skid-mounted systems built to order for mobile use.

Whether your mono pomp is part of a mining dewatering setup, wastewater plant, or food processing line, our team has the experience to get it running like new.

Signs Your Mono Pomp Needs Repair

If your pump is underperforming or failing, watch for these signs:

- Reduced flow or pressure

- Fluid leakage or seal failure

- Vibration or noise during operation

- Motor overload or tripping

- Excessive wear on rotor or stator

Early intervention saves time and prevents costly breakdowns. MultiTorque can assess your equipment and recommend either repair, upgrade, or replacement based on your needs.

Call MultiTorque for Mono Pomp Support

If you’re looking for expert support for mono pomp repairs, servicing, or part supply, MultiTorque is ready to help. Trusted by industrial clients across Australia, we bring performance, reliability, and efficiency to every job.

📞 Call now: 1300 726 525

📧 Email: sales@multitorque.com

🌐 Website: www.multitorque.com.au

🔗 LinkedIn: MultiTorque on LinkedIn