Slurry handling pumps are a critical component in industries that deal with abrasive and viscous mixtures. From mining operations to chemical processing and wastewater management, these pumps are designed to transport slurries efficiently and safely while minimising wear and maintenance costs. Choosing the right slurry handling pumps ensures operational reliability, increased productivity, and reduced downtime.

At MultiTorque, we specialise in supplying, servicing, and customising slurry handling pumps for a wide range of industrial applications. With over 15 years of experience, our team understands the unique challenges associated with abrasive and heavy-duty fluid handling, providing solutions that are tailored to meet the demands of Australian industries.

What Are Slurry Handling Pumps?

A slurry handling pump is specifically engineered to move mixtures of solids and liquids, often containing abrasive particles such as sand, ore, or chemical compounds. Unlike standard pumps, these systems are designed to withstand high levels of wear, maintain consistent flow rates, and operate reliably under harsh conditions.

The primary applications of slurry pumps include:

- Mining dewatering and mineral processing

- Wastewater treatment and effluent transfer

- Chemical processing with abrasive fluids

- Industrial material transport

By utilising robust construction materials and specialised designs, slurry pumps help industries maintain operational efficiency while protecting equipment from premature failure.

Types of Slurry Handling Pumps

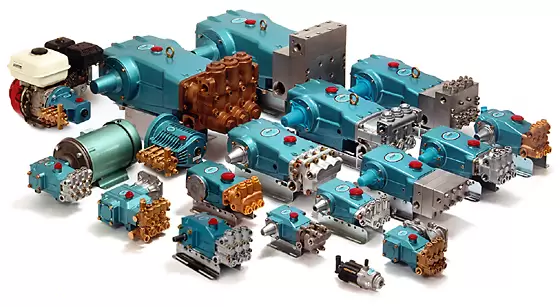

Choosing the correct type of slurry pump depends on the material properties, flow rate, and pressure requirements. MultiTorque supplies a range of solutions tailored to specific industry needs:

Centrifugal Slurry Pumps

Centrifugal slurry pumps are the most common type used in mining and heavy industrial applications. They operate by converting rotational energy into kinetic energy, allowing the fluid and solids to flow through the pump efficiently.

These pumps are ideal for:

- Transporting tailings and abrasive slurries in mining operations

- Handling water with suspended solids in wastewater facilities

- Moving chemical slurries in industrial processes

MultiTorque offers a wide range of centrifugal slurry pumps designed to maximise durability and reduce maintenance requirements.

Positive Displacement Slurry Pumps

Positive displacement pumps are particularly useful for high-viscosity slurries or applications that require consistent flow regardless of pressure changes. These pumps handle thick, abrasive fluids efficiently, making them suitable for chemical processing, mining, and wastewater applications.

They deliver precise flow rates and maintain operational stability, even under challenging conditions. MultiTorque supplies high-quality positive displacement slurry pumps and parts to ensure reliable long-term performance.

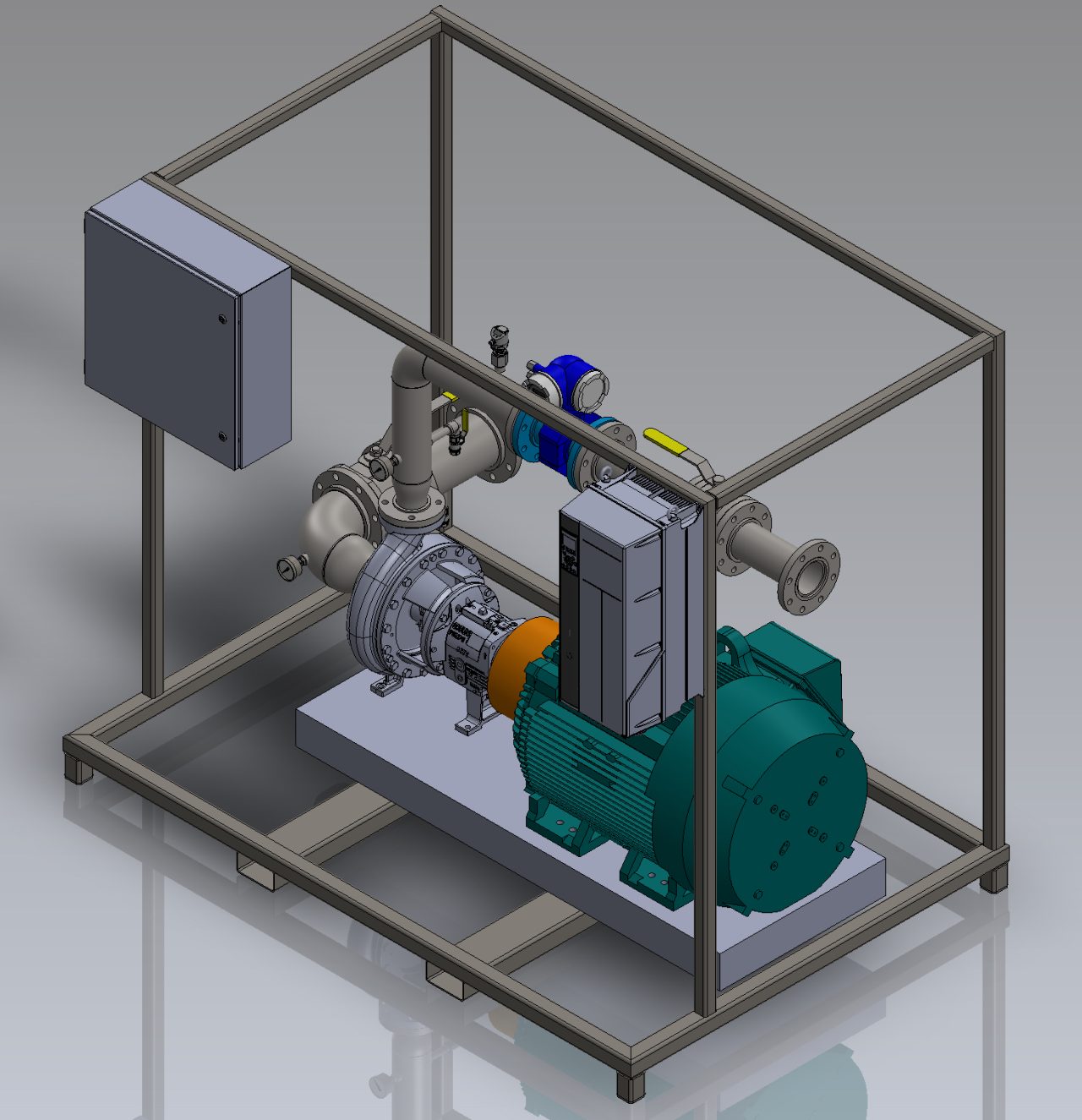

Customised Slurry Pumps

In some industries, standard slurry pumps may not meet specific operational requirements. MultiTorque offers customised solutions, including skid-mounted units and portable pumping systems, designed for:

- Remote mining sites

- Temporary dewatering projects

- Hazardous or corrosive fluid handling

Customised pumps allow businesses to optimise space, improve safety, and reduce installation time while maintaining high performance.

Materials of Construction

Slurry handling pumps must be built with materials capable of resisting wear and corrosion. Common options include:

- High-chrome alloys: Ideal for abrasive slurry applications in mining

- Stainless steel: Suitable for corrosive chemical slurries

- Rubber-lined pumps: Used in applications requiring reduced wear and energy efficiency

MultiTorque works closely with clients to determine the best materials for each application, ensuring maximum pump life and efficiency.

Advantages of Using Slurry Handling Pumps

Investing in high-quality slurry pumps offers significant benefits:

- Durability and Reliability – Designed to withstand abrasive materials, reducing the risk of pump failure.

- Improved Efficiency – Optimised designs maintain consistent flow rates and minimise energy consumption.

- Reduced Downtime – Robust construction and proper maintenance prevent costly interruptions.

- Safety Compliance – Pumps meet strict safety and environmental standards, protecting workers and the facility.

- Customisation – Skid-mounted or portable units allow flexible deployment in various industrial settings.

Maintenance and Repair of Slurry Pumps

Even the toughest slurry handling pumps require regular maintenance to ensure long-term performance. MultiTorque’s experienced technicians provide:

- Routine inspections and servicing

- Component replacement, including impellers and liners

- Full pump rebuilds and overhauls

- Emergency repair services

By scheduling consistent maintenance, businesses can extend the life of their pumps, reduce downtime, and maintain high operational efficiency.

Slurry Pump Applications in Industry

Slurry handling pumps are used across a variety of industries in Australia, including:

Mining and Mineral Processing

Slurry pumps are essential for transporting ore, tailings, and mine water efficiently. MultiTorque’s pumps withstand abrasive materials and continuous operation, making them ideal for large-scale mining operations.

Wastewater Treatment

Pumps move sludge, effluent, and other heavy liquids safely, ensuring compliance with environmental regulations. High-quality slurry pumps prevent clogging and reduce energy costs in wastewater facilities.

Chemical and Process Industries

Handling chemical slurries requires pumps resistant to corrosion and abrasion. MultiTorque supplies pumps capable of safely transporting chemicals without contamination or excessive wear.

Construction and Infrastructure

For civil works that require water removal or slurry handling, robust pumps maintain project timelines and reduce operational risk.

Why Choose MultiTorque for Slurry Handling Pumps

MultiTorque is a trusted supplier and service provider of slurry handling pumps across Australia. Our advantages include:

- Over 15 years of experience serving mining, industrial, and agricultural sectors

- Comprehensive range of centrifugal, positive displacement, and custom slurry pumps

- Expert repair and maintenance services to maximise uptime

- Custom skid solutions and portable units for remote operations

- Nationwide support with rapid response

By choosing MultiTorque, businesses gain a partner that provides reliable equipment, tailored solutions, and ongoing technical support.

Contact MultiTorque

For high-performance slurry handling pumps tailored to your operational needs, contact MultiTorque today. Our team is ready to advise on pump selection, repairs, maintenance, and custom skid systems to ensure your operations remain efficient and reliable.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

Stay connected with MultiTorque on LinkedIn for industry insights, product updates, and news about the latest in pump technology.