Mono Pumps COM: Powerful Solutions From MultiTorque 2025

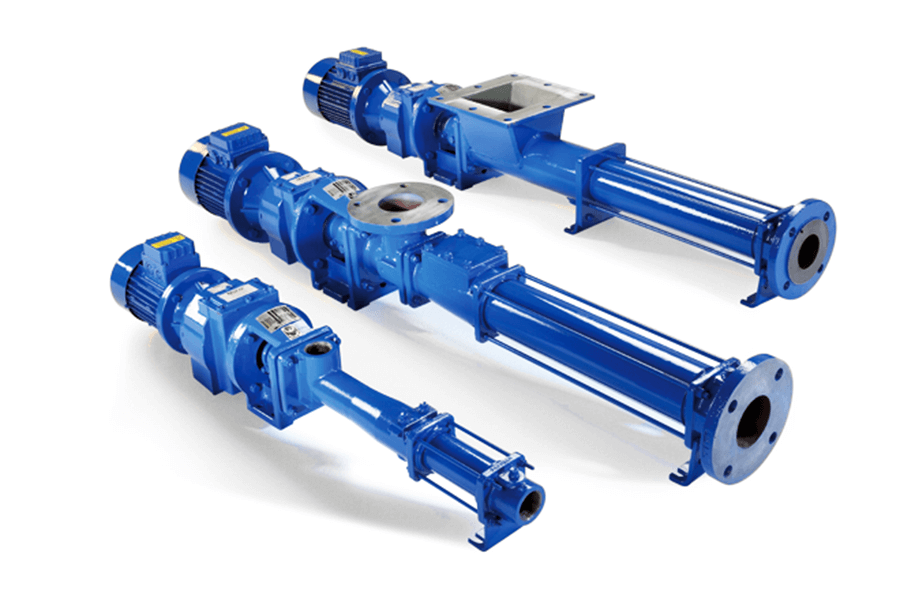

Mono Pumps COM are industry-leading progressive cavity pumps designed to provide consistent and reliable fluid transfer across a variety of industrial applications. Known for their durability, efficiency, and versatility, these pumps are widely used in sectors including chemical processing, wastewater treatment, food and beverage production, mining, and agriculture.

At MultiTorque, we specialize in supplying, servicing, and repairing Mono Pumps COM, ensuring that your operations maintain peak performance with minimal downtime.

📞 Call 1300 726 525 or email sales@multitorque.com to discuss your Mono Pumps COM requirements and receive tailored recommendations for your industrial needs.

What Are Mono Pumps COM?

Mono Pumps COM are progressive cavity pumps engineered to handle a wide range of fluid types, including viscous, abrasive, and shear-sensitive liquids. The core mechanism involves a rotor and stator system, which creates cavities to transfer fluid steadily from the pump’s suction to discharge end. This smooth, low-pulsation flow is ideal for applications requiring precise fluid handling.

For more insight into pump components, see our guides on Mono Pump Stators and Mono Pump Rotors.

Key Features and Advantages

Mono Pumps COM are built for demanding environments and heavy-duty applications. Some of their standout features include:

- High Efficiency – Optimized for minimal energy consumption while maintaining steady flow.

- Durable Construction – Designed to handle abrasive and viscous fluids reliably.

- Low Pulsation Flow – Ensures smooth, continuous fluid transfer, critical for sensitive liquids.

- Versatile Applications – Suitable for chemical, food, agricultural, mining, and industrial manufacturing sectors.

- Easy Maintenance – Rotor and stator replacement is straightforward, reducing operational downtime.

For other Mono pump options, see our articles on NOV Mono Pumps and Mono Type Pumps.

Applications of Mono Pumps COM

The versatility of Mono Pumps COM makes them suitable for a wide range of industrial applications:

- Chemical Processing – Safely transfers corrosive, viscous, or delicate chemicals without degradation.

- Wastewater Treatment – Handles sludge, slurry, and other heavy liquids efficiently.

- Food & Beverage – Maintains product integrity while pumping sensitive liquids such as oils, syrups, and sauces.

- Agriculture – Ideal for irrigation, fertilizer transfer, and liquid feed systems.

- Mining & Industrial Manufacturing – Pumps abrasive slurries, coatings, and adhesives with minimal pulsation.

For more specialized pump applications, check out Mono Jet Pumps and Mono Grifter Pumps.

Maintenance and Servicing

Maintaining Mono Pumps COM is crucial to ensure long-term efficiency and reliability. Recommended practices include:

- Routine Inspection – Regularly check rotor, stator, and drive components for signs of wear or damage.

- Timely Replacement of Components – Replace worn rotors and stators promptly to maintain optimal performance.

- Professional Servicing – MultiTorque provides in-house servicing and repair for all Mono Pumps COM, ensuring components meet manufacturer specifications and industry standards.

For additional maintenance guidance, see our resources on Mono NOV Pumps and Mono MS Pumps.

Why Choose MultiTorque for Mono Pumps COM

MultiTorque offers complete solutions for Mono Pumps COM, from supply to expert servicing and repairs:

- Industry Expertise – Over 15 years of experience in Mono pump supply and maintenance.

- In-House Workshop – Repairs and servicing are performed on-site for quality assurance and faster turnaround.

- Genuine Components – We supply original Mono parts, including Mono Screw Pumps, ensuring long-lasting performance.

- Tailored Solutions – Our team provides custom solutions based on your specific industrial needs.

Stay informed about industry updates and insights by following our LinkedIn page.

Types of Mono Pumps COM

MultiTorque offers a variety of Mono Pump COM models to suit different industrial requirements:

- Mono Merlin Pumps – Heavy-duty solutions for challenging industrial environments.

- Mono Drive Well Pump – Ideal for water extraction, dewatering, and groundwater applications.

- Mono Helical Rotor Pumps – Low-pulsation, smooth-flow pumps for sensitive fluids.

- Mono Screw Pump Variants – Designed for heavy-duty, high-volume pumping tasks.

- Mono CMM253 Pumps – Compact, reliable progressive cavity pumps for industrial fluid transfer.

- What is a Mono Pump: Uses, Benefits, and Expert Repair Services – Comprehensive guide for Mono pump selection, benefits, and maintenance.

Benefits of Using Mono Pumps COM

Investing in Mono Pumps COM offers several advantages for industrial operations:

- Enhanced Operational Efficiency – Smooth, continuous flow reduces energy usage and improves productivity.

- Reliable Performance – Built for demanding industrial conditions, ensuring long-term durability.

- Reduced Downtime – Easy maintenance and prompt servicing help prevent operational interruptions.

- Versatility – Suitable for multiple applications, making it a cost-effective investment for businesses.

- Expert Support – MultiTorque provides supply, servicing, and technical support, ensuring your pumps always perform at their best.

Conclusion

Mono Pumps COM are an essential component for industries requiring efficient, reliable, and precise fluid transfer. Their robust design, low maintenance requirements, and versatility make them a smart choice for chemical processing, wastewater management, food production, agriculture, and more.

MultiTorque offers comprehensive solutions for Mono Pumps COM, including supply, in-house repair, and expert servicing. Trust our experienced team to keep your industrial operations running smoothly and efficiently.

📞 Call 1300 726 525 or email sales@multitorque.com to discuss your Mono Pumps COM requirements and receive tailored recommendations for your industrial needs.