Diaphragm Pump Parts: Reliability and Supply with MultiTorque 2025

When it comes to industrial pumping applications, diaphragm pumps stand out as some of the most versatile and reliable systems on the market. They are trusted across industries such as mining, oil and gas, wastewater management, manufacturing, food processing, and chemical handling. But the performance of these pumps ultimately depends on the quality and reliability of their diaphragm pump parts.

At MultiTorque, we understand that downtime is costly, and reliable pumping solutions are critical for your operations. That’s why we provide high-quality diaphragm pump parts, servicing, and support across Australia. With over 15 years of experience in the industry, our team ensures that every part we supply or service is aligned with our commitment to safety, durability, and reliability.

In this guide, we’ll break down everything you need to know about diaphragm pump parts, common wear points, signs of replacement, and why MultiTorque is your go-to partner for pump maintenance and supply.

What Is a Diaphragm Pump?

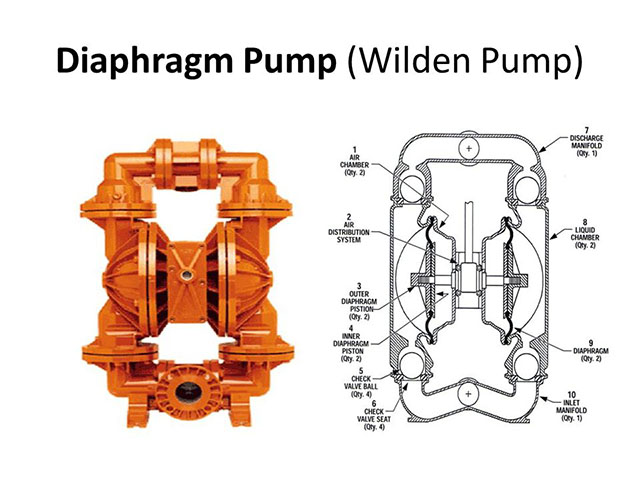

A diaphragm pump, also known as an air-operated double diaphragm (AODD) pump, is a positive displacement pump that uses compressed air to move fluid. It operates with two flexible diaphragms that reciprocate back and forth, creating a pumping action.

Because of their design, diaphragm pumps are incredibly versatile and can handle abrasive, viscous, and corrosive fluids that would damage other pump types. But like any mechanical system, performance depends on the quality and condition of its parts.

Key Diaphragm Pump Parts and Their Functions

To ensure your diaphragm pump performs reliably, each component must be in optimal condition. Below are the most critical diaphragm pump parts:

1. Diaphragms

The diaphragm is the heart of the pump. Made from materials such as rubber, PTFE (Teflon), or neoprene, diaphragms flex back and forth to displace fluid. Over time, diaphragms wear down and must be replaced to maintain consistent flow and avoid leaks.

2. Valves and Valve Balls

Check valves and valve balls control the direction of fluid flow, preventing backflow and ensuring efficiency. These parts endure constant impact and are often the first components to show signs of wear.

3. Valve Seats

The valve seats work in tandem with the valve balls to create a seal. Worn valve seats can lead to inefficiency, reduced suction, and leakage.

4. Air Distribution System

This includes the air valve and pilot mechanisms, which direct compressed air to the diaphragms. If this part malfunctions, your pump may stall or operate irregularly.

5. Seals and O-Rings

Seals and O-rings prevent leakage and ensure airtight operation. Chemical compatibility and regular inspection are crucial, as degraded seals can lead to failure.

6. Manifolds and Chambers

These control how the fluid enters and exits the pump. Cracks, corrosion, or buildup can compromise flow and efficiency.

By monitoring these key parts, operators can keep diaphragm pumps performing at their peak and avoid unexpected downtime.

Signs That Diaphragm Pump Parts Need Replacing

Recognising early signs of wear saves time, money, and production delays. Common indicators include:

- Reduced Flow Rate: Often caused by worn diaphragms or valve balls.

- Air Leakage: Faulty seals or a worn air valve can cause air to escape.

- Pump Stalling: Air distribution issues are usually to blame.

- Unusual Noises: Clicking, rattling, or grinding sounds often mean valves or seats are failing.

- Fluid Leakage: A clear sign that diaphragms or seals are compromised.

If you notice any of these symptoms, it’s best to replace the affected diaphragm pump parts before the issue escalates.

Why Quality Diaphragm Pump Parts Matter

Using genuine, high-quality parts offers multiple benefits:

- Longer Equipment Life: Reduces wear and prevents premature pump failure.

- Lower Operating Costs: Efficient pumps consume less energy and require fewer repairs.

- Reduced Downtime: Reliable parts minimise the risk of breakdowns.

- Safety and Compliance: Industrial environments demand equipment that meets strict standards.

At MultiTorque, we ensure the diaphragm pump parts we supply are manufactured to the highest standards, giving our clients confidence in every application.

MultiTorque’s Expertise in Diaphragm Pump Parts

MultiTorque supplies, services, and repairs pumps across Australia, specialising in trusted brands such as Wilden, NOV, Napco, and Orbit. Our Perth and Brisbane workshops are equipped to handle all diaphragm pump maintenance, ensuring that parts are correctly fitted, tested, and optimised for performance.

We don’t just replace parts—we assess your entire pumping system to identify the root cause of wear and prevent recurring issues. Whether you need replacement diaphragms, valve kits, or complete rebuilds, MultiTorque provides solutions tailored to your operational needs.

The MultiTorque Advantage

Choosing MultiTorque for your diaphragm pump parts offers several unique benefits:

- 15+ Years of Industry Experience – Proven expertise across multiple industries.

- Australia-Wide Support – Servicing clients from mining to agriculture.

- Quality Assured – Only supplying parts from trusted, reputable manufacturers.

- Custom Solutions – From pump trailers to specialised setups, we adapt to your requirements.

- Commitment to Safety and Reliability – Every repair and replacement aligns with our core values.

Preventative Maintenance for Diaphragm Pumps

One of the best ways to maximise pump life is through preventative maintenance. MultiTorque recommends:

- Regularly inspecting diaphragms for cracks, bulges, or wear.

- Checking seals and O-rings for chemical degradation.

- Monitoring valve performance to ensure correct sealing.

- Keeping spare parts on hand to minimise downtime.

- Scheduling regular servicing with experienced technicians.

By incorporating preventative strategies, you can significantly reduce unexpected breakdowns and extend the lifespan of your diaphragm pump parts.

Partner with MultiTorque Today

When it comes to keeping your operations running smoothly, don’t compromise on parts or service. MultiTorque is Australia’s trusted partner for diaphragm pump parts, repairs, and maintenance.

- 📞 Call us today on 1300 726 525

- 📧 Email us at sales@multitorque.com

- 🌐 Visit us online at www.multitorque.com.au

- 🔗 Connect with us on LinkedIn

With branches in Perth and Brisbane, MultiTorque ensures your pumps operate at peak performance, backed by reliable service and industry expertise.

Final Thoughts

Diaphragm pumps are essential for industries that demand reliability under tough conditions. But their performance depends on the integrity of their components. By choosing high-quality diaphragm pump parts and partnering with a trusted service provider like MultiTorque, you protect your investment, reduce downtime, and maintain safe, efficient operations.

For over 15 years, MultiTorque has been supplying, servicing, and repairing pumps with a focus on long-term client relationships. Whether you need replacement parts, complete rebuilds, or expert guidance, we’ve got you covered.