Industrial Centrifugal Pumps: The Backbone of Fluid Handling Systems 2025

When it comes to fluid transfer in industrial settings, few machines are as essential—or as widely used—as the industrial centrifugal pump. Known for their simple design, robust performance, and versatility, these pumps are the go-to solution across mining, agriculture, water treatment, and chemical processing.

At MultiTorque, we supply, service, and support high-quality centrifugal pumps tailored to meet the demands of Australia’s toughest industrial operations.

🔗 Visit MultiTorque Homepage

🔗 Connect with MultiTorque on LinkedIn

What Is an Industrial Centrifugal Pump?

An industrial centrifugal pump is a mechanical device used to move fluid by converting rotational kinetic energy into hydrodynamic energy. This energy is generated by a rotating impeller that draws liquid into the pump casing and pushes it outward through the discharge.

These pumps are ideal for:

- High-flow, low-viscosity applications

- Continuous-duty cycles

- Large-scale fluid handling with minimal maintenance

- Systems requiring high reliability and energy efficiency

How Do Centrifugal Pumps Work?

The operating principle is straightforward:

- Liquid enters the pump through the suction inlet.

- A rotating impeller increases the fluid’s velocity.

- The high-speed fluid is directed into a volute casing.

- Kinetic energy is converted into pressure, pushing fluid through the discharge outlet.

This mechanism allows for continuous flow and is ideal for systems requiring consistent, reliable pumping.

Types of Industrial Centrifugal Pumps

At MultiTorque, we supply and service a wide range of centrifugal pump designs, including:

🌊 End Suction Pumps

- Most common design for general-purpose use

- Used in HVAC, water transfer, and irrigation

- Simple maintenance and excellent flow capabilities

🔄 Multistage Centrifugal Pumps

- Multiple impellers for high-pressure applications

- Ideal for boiler feed, high-rise water supply, and long-distance pipelines

🌀 Split Case Pumps

- Double-suction design for large-volume transfer

- Excellent efficiency and durability

- Common in municipal and industrial water systems

⚙️ Self-Priming Centrifugal Pumps

- Eliminates the need for foot valves

- Great for portable and intermittent-duty applications

- Perfect for dewatering and site drainage

💧 Vertical Inline Pumps

- Space-saving vertical design

- Ideal for industrial cooling and process water systems

Key Industries That Rely on Centrifugal Pumps

| Industry | Application Example |

|---|---|

| Mining | Slurry transport, dewatering, tailings water recovery |

| Water Treatment | Filtration systems, chlorination, raw water intake |

| Agriculture | Irrigation, fertigation, livestock watering systems |

| Manufacturing | Process cooling, fluid transfer, boiler feed |

| Oil & Gas | Condensate return, injection systems, refining |

| Construction | Groundwater control, pressure boosting, sump removal |

Our team at MultiTorque helps match the right centrifugal pump to each unique fluid, flow rate, head pressure, and environmental condition.

Benefits of Industrial Centrifugal Pumps

Centrifugal pumps offer numerous benefits over other pump types, including:

✅ High Flow Rates

Centrifugal pumps deliver large volumes of fluid efficiently, making them ideal for high-throughput systems.

✅ Simplicity & Reliability

With few moving parts and a non-complex design, these pumps are easier to maintain and less prone to mechanical failure.

✅ Energy Efficiency

When properly sized and paired with a VSD (variable speed drive), centrifugal pumps operate at excellent efficiency levels, reducing long-term energy costs.

✅ Scalability

Whether you’re running a small facility or a large-scale plant, centrifugal pumps are available in a wide range of sizes and materials to meet your demands.

Common Problems (and How MultiTorque Solves Them)

Even the most reliable centrifugal pumps can face issues if not correctly installed or maintained. Here are a few examples—and how we address them:

| Problem | Cause | MultiTorque Solution |

|---|---|---|

| Cavitation | Inadequate suction pressure | System design reviews, impeller re-sizing |

| Seal leaks | Worn seals or misalignment | Seal replacements, alignment checks |

| Excessive noise/vibration | Imbalance or pipe strain | Dynamic balancing, pipework support retrofit |

| Poor performance | Incorrect pump sizing | Custom pump selection and on-site assessment |

Our technicians conduct on-site diagnostics, system audits, and full overhauls to keep your pumps running at peak performance.

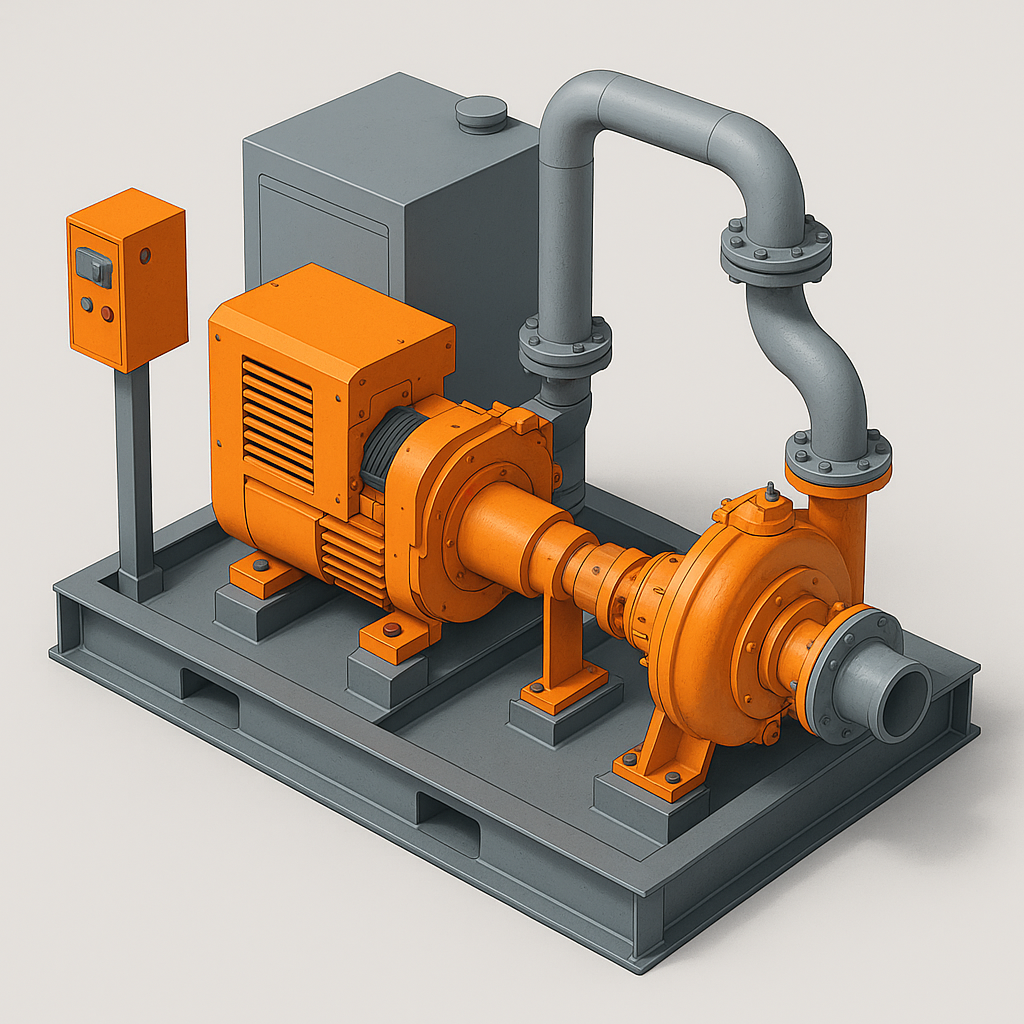

Custom Centrifugal Pump Systems

At MultiTorque, we go beyond simple pump supply. We design and build custom pump systems to suit the specific flow, pressure, and layout requirements of your site.

Our custom solutions can include:

- Skid-mounted pump sets

- Stainless steel pipework and manifolds

- VSD-controlled electric motors

- Remote control panels and telemetry

- Mobile pump trailers for site portability

If off-the-shelf doesn’t cut it, we’ll fabricate the system you need from the ground up.

Service & Maintenance

Industrial operations can’t afford downtime. That’s why we offer:

- 🛠️ Full workshop rebuilds

- 🔁 Pump exchange programs

- 📦 Genuine and aftermarket spare parts

- 🔍 On-site inspection and servicing

- 📋 Preventative maintenance contracts

We support leading brands like Flowserve, Orbit, Wilden, Napco, and more—ensuring you get reliable service regardless of your pump make.

Why Choose MultiTorque?

With over 15 years in the industry and a deep understanding of industrial fluid handling, we deliver solutions built for Australian conditions.

🧠 Expertise

Our team includes experienced technicians, electricians, and designers who understand both mechanical systems and real-world applications.

⚒️ Full-Service Support

From pump sizing and selection to installation, commissioning, and repairs—we’re with you all the way.

🚛 National Coverage

With locations in Perth and Brisbane, we service clients across WA, QLD, NSW, and VIC.

Ready to Upgrade Your Centrifugal Pump System?

Looking for a centrifugal pump that won’t quit? Whether you need a single replacement or a complete skid system, MultiTorque is your trusted partner.

📞 Call us at 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit our website

🔗 Connect on LinkedIn