Industrial Sludge Pumps: Heavy-Duty Solutions for the Toughest Waste Challenges 2025

Sludge management is one of the toughest challenges in industrial operations—thick, abrasive, and often corrosive, sludge requires a pump that won’t quit under pressure. That’s where an industrial sludge pump comes in.

From wastewater treatment to mining and food processing, industrial sludge pumps are essential for moving semi-solid materials efficiently and reliably. At MultiTorque, we supply and service robust sludge pumps designed for Australia’s harshest environments.

🔗 Visit MultiTorque Homepage

🔗 Connect with us on LinkedIn

What Is an Industrial Sludge Pump?

An industrial sludge pump is a heavy-duty pump designed to handle thick, viscous, and abrasive fluids containing solids—commonly referred to as “sludge.” Unlike clean water or light chemicals, sludge presents unique challenges including:

- High solid content

- Variable viscosity

- Corrosive or chemically reactive components

- High wear and tear on pump components

Industrial sludge pumps are specifically engineered to withstand these factors, making them a critical component in sectors like mining, wastewater treatment, agriculture, and industrial processing.

Common Types of Industrial Sludge Pumps

At MultiTorque, we supply a variety of sludge pumps to meet different industrial needs. Each type offers unique benefits depending on the application.

🌀 Progressive Cavity Pumps

- Ideal for handling viscous sludge and shear-sensitive fluids

- Low pulsation and gentle transfer

- Self-priming and suitable for variable flow conditions

- Widely used in wastewater, oil, and chemical industries

🔁 Peristaltic (Hose) Pumps

- No internal valves or seals—excellent for abrasive sludge

- Self-priming and dry-run capable

- Easy to clean and maintain

- Common in chemical dosing and food waste applications

💨 Air Operated Double Diaphragm (AODD) Pumps

- Excellent for portable or intermittent use

- Handles thick sludges and slurries

- Safe for explosive or hazardous areas

- Popular in mining and remote site operations

🛠️ Submersible Sludge Pumps

- Designed to be fully submerged

- Ideal for pits, tanks, and confined spaces

- Built with high wear-resistance for continuous duty

Where Are Industrial Sludge Pumps Used?

Sludge is produced in a wide range of industries—each with its own set of challenges. Here’s how industrial sludge pumps are applied across sectors:

| Industry | Application Example |

|---|---|

| Mining | Tailings transfer, thickener underflow, slurry pumping |

| Wastewater Treatment | Sludge dewatering, grit removal, biosolid handling |

| Food Processing | Organic waste, mash transfer, high-viscosity fluids |

| Construction | Mud removal, excavation drainage, tunneling operations |

| Oil & Gas | Drilling mud, separator sludge, tank bottom cleanouts |

| Agriculture | Effluent pumping, manure handling, compost systems |

At MultiTorque, we assess the specific needs of your operation—flow rate, solid content, pH levels, chemical compatibility—and recommend the right sludge pump for the job.

Key Features of a Good Industrial Sludge Pump

When dealing with sludge, not just any pump will do. Look for the following characteristics:

- ✅ Abrasion Resistance – Components like hardened impellers, ceramic linings, or elastomers protect against wear

- ✅ Seal Protection – Heavy-duty mechanical seals or seal-less designs reduce failure risk

- ✅ High Torque, Low Speed – Essential for pushing thick sludge without overheating or clogging

- ✅ Variable Flow Control – VSD compatibility allows for fine-tuned performance

- ✅ Easy Maintenance – Quick disassembly and spare part availability save valuable downtime

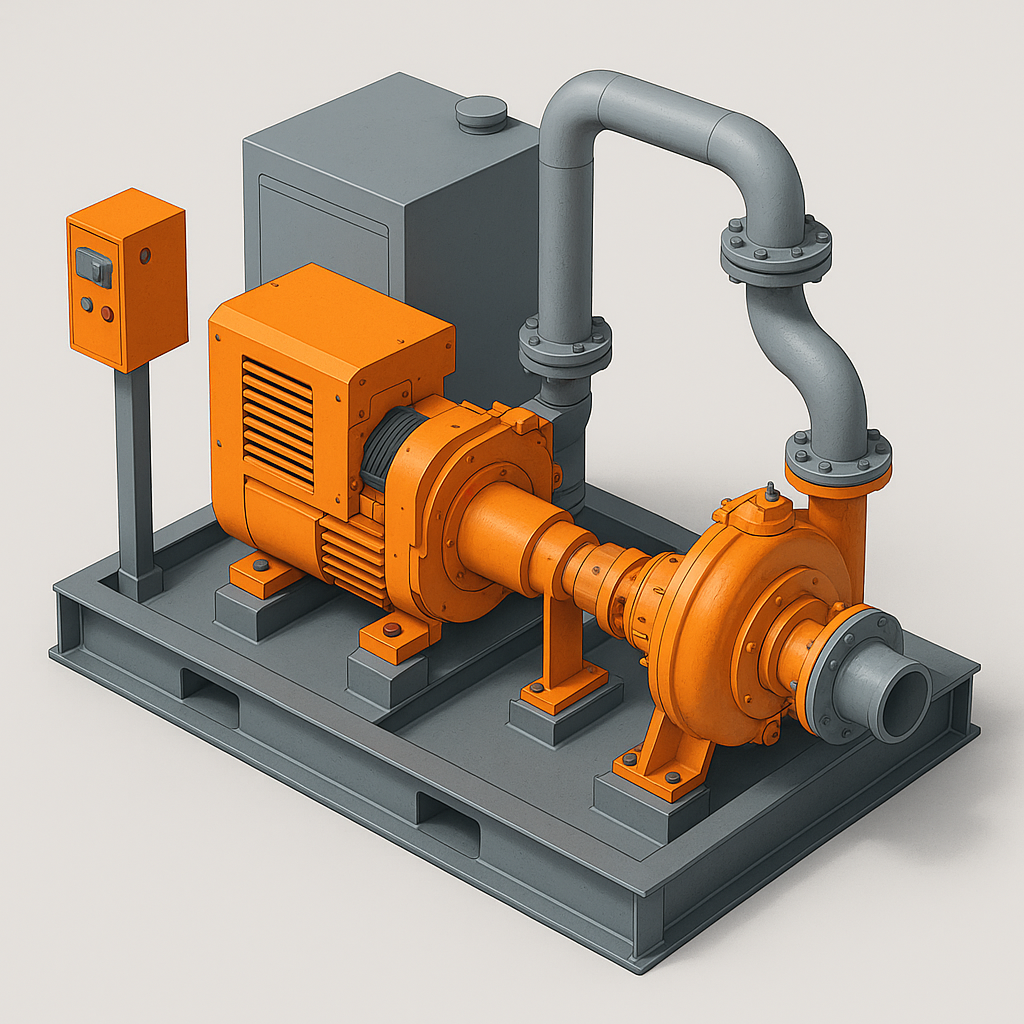

Custom Sludge Pump Systems from MultiTorque

Need a skid-mounted sludge pump with integrated controls? Or a trailer unit for mobile dewatering? We’ve got you covered.

Our in-house team of engineers and fabricators can build you a custom pumping solution, complete with:

- Stainless steel pipework and housings

- Explosion-proof motors (if required)

- Variable speed drives and soft starters

- Automated level and flow control systems

- Telemetry for remote monitoring

Every site is different—and we tailor every system to match.

Maintenance & Servicing

Due to the aggressive nature of sludge, regular servicing is essential. MultiTorque offers:

- 🧰 Pump overhauls and rebuilds (in our Perth and Brisbane workshops)

- 🔁 Exchange programs to reduce lead times

- 🔍 On-site diagnostics and performance testing

- 📦 Genuine and aftermarket spare parts for major brands

- 🛡️ Preventative maintenance scheduling

We work with leading pump manufacturers including Netzsch, Wilden, Orbit, and more—backed by full support and documentation.

Why Choose MultiTorque?

We’re not just suppliers—we’re problem-solvers with real-world experience and a commitment to reliability.

🔧 15+ Years of Experience

We understand the harsh conditions of Australian industry and build pump systems to match.

🌏 National Coverage

With service hubs in Perth and Brisbane, we support operations across WA, QLD, and beyond.

⚙️ Custom Engineering

We don’t just sell pumps—we build systems that keep your plant flowing, no matter the conditions.

💬 Dedicated Support

From pre-sale consultation to after-sale servicing, we’re with you every step of the way.

Get a Sludge Pump That Gets the Job Done

If your current pump is struggling with blockages, leaks, or wear—it’s time to upgrade. Let MultiTorque help you spec, supply, and support a reliable industrial sludge pump built for your conditions.

📞 Call: 1300 726 525

📧 Email: sales@multitorque.com

🌐 www.multitorque.com.au

🔗 Follow us on LinkedIn