Helical Rotor Pump: The Ultimate Guide for Industrial Applications 2025

A helical rotor pump, also known as a progressive cavity pump, is a powerful and versatile solution for moving thick, viscous, or abrasive fluids. At MultiTorque, we specialise in supplying and servicing helical rotor pumps across a wide range of industries in Australia. Whether you’re dealing with mining slurry, wastewater, or oil transfer, these pumps are built to handle the toughest conditions while delivering reliable, consistent performance.

In this guide, we’ll break down how helical rotor pumps work, their key benefits, common applications, and what makes MultiTorque your go-to supplier for everything pump-related.

What is a Helical Rotor Pump?

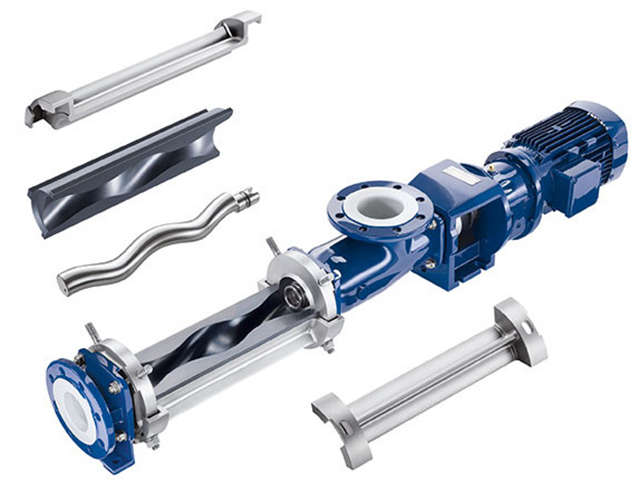

A helical rotor pump is a type of positive displacement pump designed to move fluids through a sealed cavity. It features two main components: a single-helix metal rotor and a double-helix elastomer stator. As the rotor turns inside the stator, cavities form and move along the pump, carrying fluid from the inlet to the outlet.

Unlike centrifugal pumps, which rely on high-speed rotation and impellers, helical rotor pumps excel at delivering constant, low-pulsation flow rates even with viscous or solid-laden fluids.

How Does a Helical Rotor Pump Work?

The working principle of a helical rotor pump is based on progressive cavity movement. Here’s a quick breakdown:

- The rotor rotates inside the stator, creating tightly sealed cavities.

- These cavities move in a progressive manner along the axis of the pump.

- As the rotor turns, fluid is transported through these cavities from the suction side to the discharge side.

- The continuous motion ensures smooth, pulse-free flow.

Because the internal clearances are tight, the pump is also capable of self-priming, making it ideal for applications where suction lift is needed.

Key Benefits of Helical Rotor Pumps

At MultiTorque, we recommend helical rotor pumps for applications where precision, durability, and efficiency matter. Here are some of the core advantages:

✅ 1. Excellent for High Viscosity Fluids

Helical rotor pumps can handle everything from thick sludge and oils to food pastes and chemicals. Their ability to process highly viscous fluids without clogging sets them apart from standard pump designs.

✅ 2. Low Pulsation Flow

Unlike piston or diaphragm pumps, helical rotor pumps deliver a smooth, near-laminar flow. This is especially important for dosing, metering, or fluid transfer applications that require consistent pressure.

✅ 3. Gentle Handling of Shear-Sensitive Materials

Because the fluid experiences minimal turbulence and shear, these pumps are ideal for sensitive products like emulsions, polymers, and even certain food-grade materials.

✅ 4. Self-Priming Capability

Helical rotor pumps can draw fluid even when positioned above the fluid level. This makes them suitable for tank unloading, sump emptying, or mobile trailer units.

✅ 5. High Suction and Discharge Pressures

They can develop significant suction and discharge pressure, making them effective even in demanding environments like dewatering, mining, or industrial waste handling.

Common Applications in Australia

MultiTorque has supplied and serviced helical rotor pumps across sectors such as:

- Mining – for dewatering slurry, thickened tailings, or abrasive fluids.

- Wastewater Treatment – ideal for sludge, scum, and digested biosolids.

- Oil and Gas – effective in moving crude oil, lubricants, and drilling mud.

- Agriculture – for irrigation, manure handling, and molasses transfer.

- Food Processing – handling syrups, dairy, fruit pastes, and other viscous products.

If you’re looking for a rugged and efficient pump that thrives in harsh Australian conditions, a helical rotor pump from MultiTorque is your answer.

Maintenance and Servicing

One of the key advantages of working with MultiTorque is our comprehensive pump service and repair capability. Helical rotor pumps require periodic inspection of:

- Rotor and stator wear

- Seals and gaskets

- Drive coupling and shaft alignment

Our experienced team can perform on-site diagnostics, rebuilds, or complete overhauls, extending the life of your equipment and minimising downtime.

We also stock a wide range of spare parts and offer custom trailer builds for mobile dewatering units powered by helical rotor pumps.

Why Choose MultiTorque?

MultiTorque has built a solid reputation for supplying, maintaining, and customizing helical rotor pumps for clients across Australia. Here’s what sets us apart:

🔧 Custom Builds

We offer custom-designed skid and trailer pump units tailored to your needs. Whether it’s a mining site in WA or a wastewater plant in QLD, we deliver practical pumping solutions.

🧰 Expert Technicians

Our team of trained technicians understands the ins and outs of positive displacement pumps. From diagnostics to full rebuilds, you’re in safe hands.

🚛 Fast Turnaround

We know downtime is costly. Our Perth and Brisbane branches allow us to dispatch parts and technicians quickly.

🤝 Long-Term Support

We’re not just here for a quick sale. We’ve been in the industry for 15+ years and focus on long-term client relationships built on reliability and trust.

Get the Right Helical Rotor Pump for Your Application

Not all helical rotor pumps are created equal. The correct size, stator material, and configuration can drastically impact performance and longevity.

MultiTorque works with leading pump brands like:

- Napco

- Orbit

- NOV

- Wilden (for complementary air-operated options)

Let us help you select the best solution for your site or application. Whether you need a standalone pump, a complete trailer unit, or ongoing servicing, our team will guide you every step of the way.

Contact MultiTorque Today

Ready to upgrade your operation with a reliable, high-performance helical rotor pump?

📞 Call us now on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

🔗 Follow us on LinkedIn

Let MultiTorque provide the muscle behind your flow. We bring the torque – you get the results.