Air Start Diesel Systems: Efficient and Reliable Engine Starting Solutions 2025

Air start diesel systems are widely used in heavy-duty applications where reliable engine starting is critical. From marine vessels and power generators to large industrial engines, these systems provide a powerful, safe, and efficient method to start diesel engines, especially those with large cylinders and high compression ratios.

If you’re exploring solutions for dependable engine starts, understanding how air start diesel systems work and the benefits they offer is essential.

What Is an Air Start Diesel System?

An air start diesel system uses compressed air to turn over a diesel engine during startup instead of relying on electrical starters. The system stores compressed air in high-pressure tanks and releases it through air starters that engage the engine’s flywheel or crankshaft, generating the torque needed to start combustion.

These systems are common in large engines where electric starters would require excessive power or be impractical due to engine size.

How Do Air Start Diesel Systems Work?

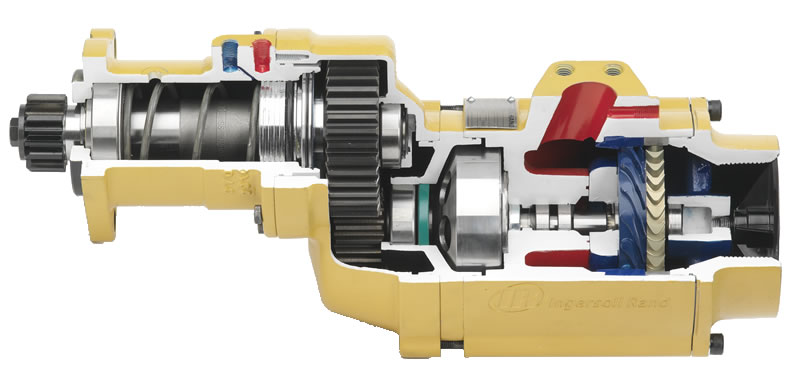

The main components of an air start diesel system include:

- Air Compressor: Generates compressed air stored in receivers (tanks).

- Air Receivers: High-pressure tanks storing the compressed air.

- Air Starter Motor: Converts compressed air energy into mechanical torque to crank the engine.

- Control Valves and Pipes: Manage airflow from the receivers to the starter motor.

- Governor and Safety Devices: Ensure proper air pressure regulation and system protection.

When starting the engine, the system releases compressed air into the air starter motor, which spins the engine’s flywheel to initiate the combustion process. Once the engine fires and runs independently, the air start system disengages.

Advantages of Air Start Diesel Systems

Air start diesel systems offer several benefits, especially in demanding environments:

- High Torque Output: Provides powerful starting torque suitable for large diesel engines.

- Reliability: Less prone to electrical failures since it does not depend on battery power.

- Safety: Reduced risk of sparks or electrical hazards, important in explosive or marine environments.

- Low Maintenance: Fewer moving parts compared to electric starters result in lower maintenance needs.

- Quick Start: Enables rapid and repeated engine starts, beneficial in emergency or backup power situations.

Typical Applications of Air Start Diesel Systems

- Marine Engines: Ships and boats with large engines rely on air start systems for dependable starting.

- Power Generation: Diesel generators in remote or industrial settings use air starters for consistent operation.

- Heavy Machinery: Construction and mining equipment with large diesel engines often utilize air start technology.

- Locomotives: Rail engines benefit from air start systems for robust engine starts.

Choosing the Right Air Start Diesel System Manufacturer

Selecting a trusted manufacturer is key to ensuring high performance and durability. Look for manufacturers who offer:

- High-Quality Components: Durable materials and precision engineering.

- Custom Solutions: Tailored systems for specific engine sizes and applications.

- After-Sales Support: Technical assistance and maintenance services.

- Compliance: Products meeting industry standards and safety regulations.

MultiTorque: Your Air Start Diesel System Partner in Australia

For reliable air start diesel systems in Australia, MultiTorque provides expert supply, service, and custom solutions. With extensive experience in industrial pumps and engine systems, MultiTorque offers:

- High-quality air start systems compatible with a wide range of diesel engines.

- Customized installations and maintenance support.

- Fast delivery and technical expertise across Australia.

Contact MultiTorque at 1300 726 525 or email sales@multitorque.com to discuss your air start diesel system needs today. https://www.linkedin.com/company/3176927