Stainless Steel Progressive Cavity Pump: Built Tough for the Harshest Fluids 2025

When it comes to pumping aggressive, corrosive, or hygienic fluids, a stainless steel progressive cavity pump stands out as the top-tier solution. Designed for durability, chemical resistance, and easy cleaning, this pump is the go-to choice across food, beverage, chemical, and wastewater industries.

When it comes to pumping aggressive, corrosive, or hygienic fluids, a stainless steel progressive cavity pump stands out as the top-tier solution. Designed for durability, chemical resistance, and easy cleaning, this pump is the go-to choice across food, beverage, chemical, and wastewater industries.

At MultiTorque, we supply, service, and repair stainless steel progressive cavity pumps for Australian clients who demand reliable performance—every time. Whether you need a full pump system, a single unit, or expert servicing, we’ve got you covered from Perth to Brisbane.

What Is a Stainless Steel Progressive Cavity Pump?

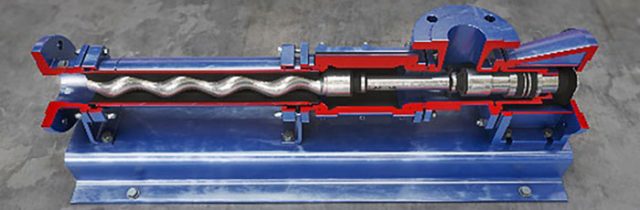

A progressive cavity pump is a type of positive displacement pump that uses a helical rotor turning inside a double-helix stator to move fluid through a series of sealed cavities. When constructed with stainless steel, this pump gains several advantages:

-

Superior corrosion resistance

-

Compatibility with food-grade applications

-

Increased mechanical strength

-

Easy to clean and sterilise

-

Long service life in tough environments

Whether you’re pumping caustic chemicals or thick food pastes, stainless steel construction keeps your system clean, safe, and running smoothly.

Key Features & Benefits

1. Corrosion Resistance

316 stainless steel construction resists acids, alkalis, saltwater, and other aggressive media—essential for chemical and wastewater applications.

2. Hygienic Design

Ideal for food and beverage industries. Stainless steel pumps meet hygienic standards, and many models can be CIP (clean-in-place) compatible.

3. Low-Shear Pumping

Gentle movement ensures shear-sensitive fluids like yogurt, cream, or emulsions maintain consistency and integrity.

4. Handles Viscous and Abrasive Fluids

Whether it’s sludge, slurry, resin, or pulp, this pump handles tough fluids with ease.

5. Steady, Pulsation-Free Flow

The progressive cavity mechanism guarantees a non-pulsating, continuous flow—even under varying pressure conditions.

Common Industries Using Stainless Steel Progressive Cavity Pumps

At MultiTorque, we serve a diverse range of sectors that rely on stainless steel PC pumps:

-

Food & Beverage – Fruit pulp, molasses, syrups, dairy

-

Chemical Processing – Acids, polymers, flocculants

-

Water Treatment – Sludge, pH balancing agents

-

Cosmetics – Lotions, gels, creams

-

Pharmaceutical – Sterile, low-shear fluid transfer

-

Mining & Oil – Where corrosion resistance is essential

Each industry has unique challenges—and that’s why we offer tailored solutions based on flow rates, viscosities, and environmental conditions.

Custom-Built Stainless Steel Pump Systems

Need more than a standalone pump? MultiTorque designs and builds custom stainless steel progressive cavity pump systems on skids, trailers, or mobile units. We also retrofit existing pump bases and piping for clients upgrading from cast iron or plastic units to stainless steel.

We consider everything—from fluid characteristics to power sources—to deliver a turnkey package that performs reliably and safely.

Repairs, Servicing & Spare Parts

Our technicians are trained to maintain and rebuild stainless steel PC pumps for top brands such as Netzsch, Mono, Orbit, NOV, and more. We offer:

-

Rotor and stator replacements

-

Seal and gasket overhauls

-

Corrosion damage repair

-

Laser alignment and flow testing

-

Spare parts and performance upgrades

With locations in Perth and Brisbane, our service reach spans across mining towns, remote sites, and industrial zones throughout Australia.

Get Stainless Steel Progressive Cavity Pump Support Today

If you’re operating in a corrosive or food-grade environment, don’t risk downtime or contamination with inferior materials. Choose stainless steel—and choose MultiTorque for expert advice and long-term support.

📞 Call us today on 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au