Progressive Cavity Sludge Pump: The Powerful Solution for Viscous Waste Handling 2025

When dealing with thick, abrasive, or fibrous sludges, standard centrifugal pumps often struggle. Enter the progressive cavity sludge pump—a robust and precise pumping solution designed for high-viscosity, solid-laden media. If you need reliable, non-clogging sludge transfer, this is the pump to count on.

At MultiTorque, we supply, service, and repair progressive cavity pumps across Australia. Whether you’re managing wastewater, mining slurry, or agricultural effluent, we’ve got the right equipment and experience to support your operation.

What Is a Progressive Cavity Sludge Pump?

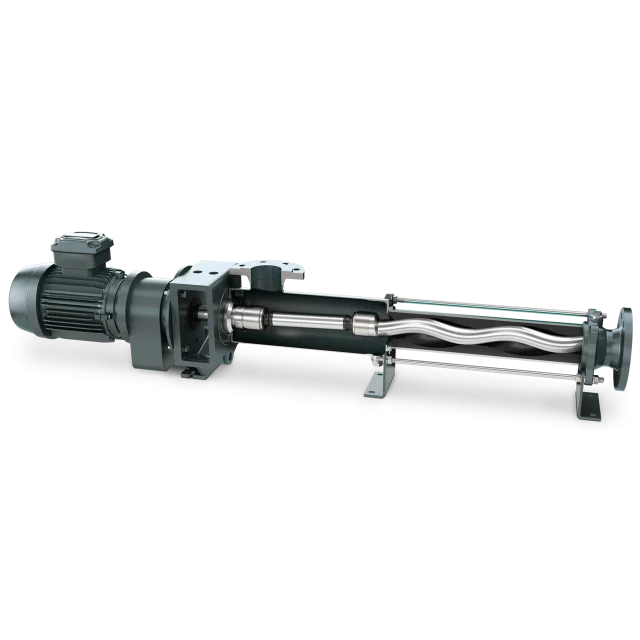

A progressive cavity sludge pump is a type of positive displacement pump engineered for moving highly viscous, solid-rich, or shear-sensitive fluids. It works by rotating a helical rotor inside a matching stator, forming sealed cavities that transport the fluid smoothly through the pump.

This design allows the pump to:

-

Handle sludges with high solids content

-

Provide consistent flow without pulsation

-

Operate under high pressure with minimal backflow

Because of its ability to maintain flow rate regardless of viscosity or pressure changes, it’s ideal for sludge handling across multiple sectors.

Ideal for Challenging Sludge Applications

Sludge is typically a mix of water, organic and inorganic solids, and sometimes chemicals—making it a difficult medium for most pumps. Progressive cavity pumps shine in applications such as:

-

Wastewater treatment – Thickened activated sludge, digester feed, scum transfer

-

Mining – Tailings, mineral-rich slurry, and thick chemical sludge

-

Agriculture – Effluent handling, manure slurry, compost tea

-

Industrial waste – Food byproducts, paint sludge, oil-water emulsions

Key Features & Benefits

✔️ Solids Handling: Easily handles sludge with fibrous or gritty content

✔️ Low Shear Transfer: Prevents emulsification or breakdown of materials

✔️ Self-Priming: Effective in both suction lift and flooded applications

✔️ Continuous, Pulsation-Free Flow: Ensures smooth system operation

✔️ Easy to Maintain: Modular components make repairs simple

Pump Design: Built for Tough Conditions

The core components include:

-

Rotor: A metal helical shaft

-

Stator: An elastomer-lined housing that matches the rotor’s shape

-

Drive: Often gearbox-equipped to provide torque and flow control

-

Suction/Discharge Ports: Sized for high-solids throughput

When paired with variable frequency drives (VFDs), these pumps provide excellent control over flow rates, making them adaptable to seasonal or variable load conditions.

Trusted Brands We Support

At MultiTorque, we use the top brands in the sludge pump category, including:

-

Netzsch

-

Mono

-

Orbit

-

Mononov

We also stock aftermarket or OEM parts, including rotors, stators, seals, and gearboxes. Our repair workshop can handle anything from routine seal changes to full system rebuilds.

Why Choose MultiTorque?

With over 15 years in the industry, MultiTorque is a trusted name in Australian pump supply and servicing. We understand the harsh realities of sludge pumping and offer fast, honest, and effective support.

What you get with us:

-

🛠️ In-house repair facilities

-

🚚 On-site service options across WA & QLD

-

🔧 Custom solutions including mobile trailer setups

-

🧠 Expert advice for matching the right pump to your system

Whether you’re installing new sludge systems or upgrading aging infrastructure, we’re your go-to team.

Get in Touch with MultiTorque Today

If you’re looking for a reliable progressive cavity sludge pump, speak to the experts at MultiTorque. We’ll guide you through the best options, deliver fast turnaround on parts and servicing, and keep your system running with minimal downtime.

📞 Call 1300 726 525

📧 Email: sales@multitorque.com

🌐 Visit: www.multitorque.com.au

Let’s keep the sludge moving—and your operations flowing.