6 Powerful Reasons Industrial Gear Pumps Dominate Fluid Transfer Applications

When it comes to rugged, reliable, and precise fluid transfer, industrial gear pumps are the unsung heroes across countless sectors. From chemical processing to mining and oil transfer, these workhorses are built to handle high-viscosity fluids with minimal fuss. In this article, we break down the key reasons why gear pumps remain the top choice for demanding industrial applications.

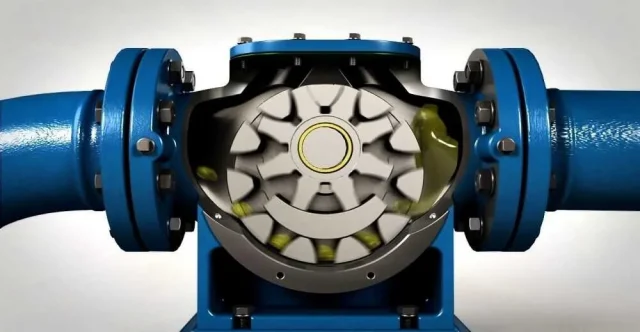

What is an Industrial Gear Pump?

An industrial gear pump is a type of positive displacement pump that uses meshing gears to pump fluid by displacement. This consistent flow makes them ideal for oil, chemicals, adhesives, and fuel—even under extreme conditions.

There are two primary types:

-

External gear pumps – use two identical gears to create flow.

-

Internal gear pumps – use an inner and outer gear for quieter, smoother operation.

1. High Efficiency for Viscous Fluids

Industrial gear pumps shine when handling high-viscosity materials like oils, syrups, or molasses. Their robust design ensures minimal slippage and highly efficient flow, even at low speeds or high pressures.

| Fluid Type | Suitable Gear Pump? | Notes |

|---|---|---|

| Motor oil | ✅ | Smooth flow, no pulsation |

| Resin | ✅ | High torque capabilities |

| Water (low-viscosity) | ❌ | Less efficient than centrifugal |

2. Precise Flow Control

Gear pumps provide fixed displacement per revolution, allowing for highly accurate and repeatable flow. This makes them ideal for metering and dosing applications where consistency is key—especially in industries like food production or chemical batching.

3. Compact Yet Powerful Design

Don’t let their size fool you. Gear pumps offer impressive pressure ratings, often up to 3000 PSI, in a compact footprint. This space-saving design allows for easier integration into skids, trailers, and mobile units, without sacrificing performance.

4. Built for Durability

Industrial gear pumps are built from high-strength materials like cast iron, stainless steel, and bronze. This ensures long-lasting resistance to wear, corrosion, and abrasion—making them an ideal fit for 24/7 operations in mining, oil & gas, and marine sectors.

5. Low Maintenance, High ROI

One of the biggest advantages of gear pumps is their simple mechanical design. With few moving parts and no valves, maintenance is minimal. This lowers the total cost of ownership, reduces downtime, and provides a high return on investment over time.

6. Trusted Australian Supplier – MultiTorque

If you’re in Australia and need a tough, industrial-grade gear pump, look no further than MultiTorque. With over 15 years of experience in the industry, we supply, service, and repair a wide range of industrial pumps for mining, chemical, and oil applications.

Our team specializes in:

-

Sourcing external and internal gear pumps

-

On-site installation and servicing

-

Custom solutions for high-pressure or high-viscosity systems

Whether you’re upgrading your system or tackling a brand-new build, MultiTorque’s expert team will keep your flow under control.

Get in Touch

Call 1300 726 525 or visit https://www.multitorque.com.au to speak with our team about industrial gear pump solutions tailored to your needs.