5 Reasons Why a Vertical Water Pump is the Ultimate Choice for Industrial Efficiency

5 Reasons Why a Vertical Water Pump is the Ultimate Choice for Industrial Efficiency

When it comes to handling water transfer in large-scale industrial operations, vertical water pumps are the unsung heroes that keep systems running smoothly. Whether you’re managing a cooling tower, irrigation system, or a high-rise building’s water supply, a vertical pump offers unbeatable performance, space-saving design, and long-term durability.

At MultiTorque, we understand the importance of reliable, high-performing pumps—and vertical water pumps are at the top of the list when it comes to power and precision.

What Is a Vertical Water Pump?

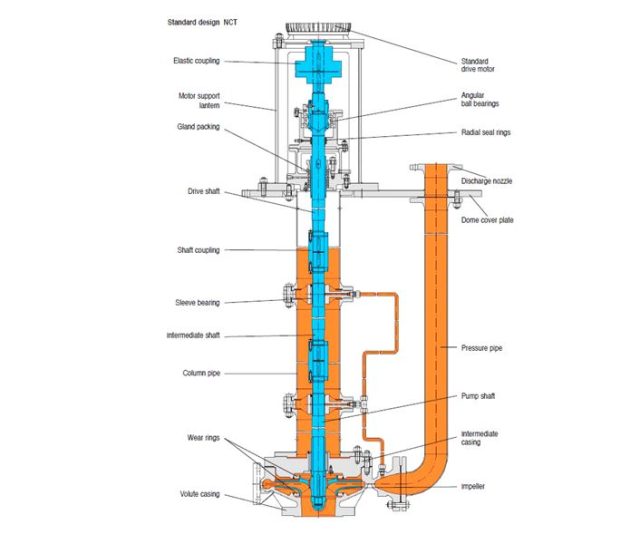

A vertical water pump is a type of centrifugal pump designed with the motor located above the pump, connected through a vertical shaft. These pumps are ideal for situations where space is limited or where suction lift is required from a deep source like a pit, tank, or sump.

Because of their construction, vertical pumps are often used in:

-

Industrial water treatment

-

Municipal water supply

-

Boiler feed applications

-

Agricultural irrigation

-

Firefighting systems

Their modular design also makes maintenance simpler and system upgrades more cost-effective.

Top 5 Advantages of Vertical Water Pumps

1. Space-Efficient Design

One of the biggest benefits of vertical pumps is their compact footprint. They’re designed to fit into narrow spaces where horizontal pumps wouldn’t be feasible. If you’re operating in a facility where floor space is at a premium, vertical pumps are a no-brainer.

2. High Performance for Deep Sumps

Vertical pumps shine when it comes to deep-well pumping. With extended shafts and bowls placed below the water surface, these pumps can efficiently draw water from depths that would challenge other pump types.

3. Long-Term Durability

Built to last, vertical pumps are typically made from corrosion-resistant materials such as stainless steel or ductile iron. They’re engineered to withstand the rigors of industrial use, offering longer service life and reduced downtime.

4. Easy Maintenance and Upgrades

Vertical water pumps feature a modular design, meaning that individual parts can be repaired or replaced without dismantling the entire system. This saves time and significantly lowers long-term maintenance costs.

5. Energy Efficiency

These pumps are not just strong—they’re smart. With the right motor and controls, vertical pumps can be paired with Variable Frequency Drives (VFDs) to optimize performance and reduce energy usage by up to 30%.

Where Are Vertical Water Pumps Used?

Due to their efficiency and adaptability, vertical pumps are found in a wide range of industries:

| Industry | Application |

|---|---|

| Power Generation | Cooling towers, boiler feeds |

| Agriculture | Irrigation and drainage |

| Water Utilities | Distribution and supply |

| Manufacturing | Cooling and process water |

| Construction | Dewatering and groundwater removal |

Their versatility makes them a trusted choice in environments where reliability is non-negotiable.

Why Choose MultiTorque for Vertical Water Pumps?

At MultiTorque, we supply and service top-tier vertical water pumps across Australia. With 15+ years of experience, a team of dedicated technicians, and a nationwide support network, we’re ready to help you find the perfect solution for your application.

We offer:

-

Custom pump configurations

-

Fast lead times and expert servicing

-

On-site installation and maintenance support

Explore our industrial pump range at 👉 https://www.multitorque.com.au

https://www.linkedin.com/company/3176927

Or give us a call at 1300 726 525 to speak to a pump expert today.

Final Thoughts

If you’re looking for a high-performance, space-saving, and durable water transfer solution, a vertical water pump is the clear winner. It delivers the power, efficiency, and long-term reliability you need—especially when sourced and supported by a trusted supplier like MultiTorque.